More Information

Submitted: April 15, 2024 | Approved: April 30, 2025 | Published: May 01, 2025

How to cite this article: Rahimi P. Investigation of Fuel Cells under Transient (Dynamic) Conditions to Improve the Efficiency of Polymer Electrolyte Fuel Cells in Dead-Ended Anode Mode: Review Article. Ann Civil Environ Eng. 2025; 9(1): 012-017. Available from:

https://dx.doi.org/10.29328/journal.acee.1001075

DOI: 10.29328/journal.acee.1001075

Copyright license: © 2025 Rahimi P. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Investigation of Fuel Cells under Transient (Dynamic) Conditions to Improve the Efficiency of Polymer Electrolyte Fuel Cells in Dead-Ended Anode Mode: Review Article

Parsa Rahimi*

Department of Energy Engineering System, Faculty of Engineering Modern Technologies, Amol University of Special Modern Technologies, Iran

*Address for Correspondence: Parsa Rahimi, MSc Student of Energy Engineering Systems, Department of Energy Engineering System, Faculty of Engineering Modern Technologies, Amol University of Special Modern Technologies, Iran, Email: [email protected]

Polymer Electrolyte Membrane Fuel Cells (PEMFCs) operating in Dead-Ended Anode (DEA) mode present a promising alternative to traditional flow-through systems by simplifying design and reducing costs. However, their efficiency and durability are challenged by transient phenomena such as water accumulation, nitrogen buildup, and carbon corrosion throughout operation. This review investigates the dynamic behavior of DEA PEMFCs under dynamic operating states, aiming to improve their efficiency. By analyzing purge cycle optimization and transient response characteristics, we identify strategies to mitigate hydrogen loss, maintain voltage stability, and extend stack lifetime. The key findings indicate that precise purge scheduling and effective water management are critical for optimizing performance, with dynamic models providing insights into time-dependent processes. This study underscores the potential of DEA PEMFCs for high-efficiency applications provided transient effects are effectively managed.

Proton Exchange Membrane Fuel Cells (PEMFCs) are increasingly valued for their high efficiency and low environmental impact [1,2], making them viable for use in automotive, stationary, and portable power systems. In Dead-Ended Anode (DEA) mode, hydrogen is supplied at a regulated pressure without recirculation, eliminating reliance on complex balance-of-plant (BOP) components like ejectors and humidifiers found in Flow-Through Anode (FTA) systems. This simplification enhances practicality by reducing system weight, volume, and cost. However, DEA operation introduces dynamic challenges, including the accumulation of nitrogen and liquid water in the anode channel, which leads to hydrogen starvation, voltage drops, and cathode carbon corrosion over time.

Dynamic operating states—such as startup, load changes, and purge events—significantly influence DEA PEMFC performance. Understanding these dynamics is essential for optimizing efficiency** (defined as the ratio of energy output to hydrogen fuel input (Foot note)), while minimizing degradation. Research by Chen et al. [3] explores purge cycle optimization to balance hydrogen utilization and durability, while Moçotéguy, et al. [4] examine transient responses to current steps, highlighting water management’s role in performance decline. This review synthesizes these studies to investigate DEA PEMFCs under dynamic operating states, aiming to enhance efficiency through improved purge strategies and dynamic modeling. The objectives are to: (1) evaluate the impact of transient phenomena on efficiency [5], (2) assess methods for optimizing purge cycles, and (3) propose approaches to mitigate degradation in DEA mode.

This review draws on two seminal studies from the provided document: Chen, et al. [3] and Moçotéguy, et al. [4], and supplemented with additional peer-reviewed sources.

The methodology encompasses:

1. Source selection

The chosen articles focus on DEA PEMFC dynamics and efficiency. Chen, et al. provide a model-based approach to purge optimization, while Moçotéguy, et al. offer experimental and simulation insights into transient behavior [6].

2. Modeling techniques

- Chen, et al. [3] developed a two-phase, 1+1D model simulates anode channel dynamics, including nitrogen and water accumulation, carbon corrosion, and purge flow (e.g., Eq. 2). Efficiency (η) is calculated over multiple cycles (Eq. 1) [7], with purge intervals scanned (20-900 ms) to identify optima. The model was validated with a single-cell experiment (50 cm² MEA, 0.6 A/cm², 50 °C).

(1)

(2)

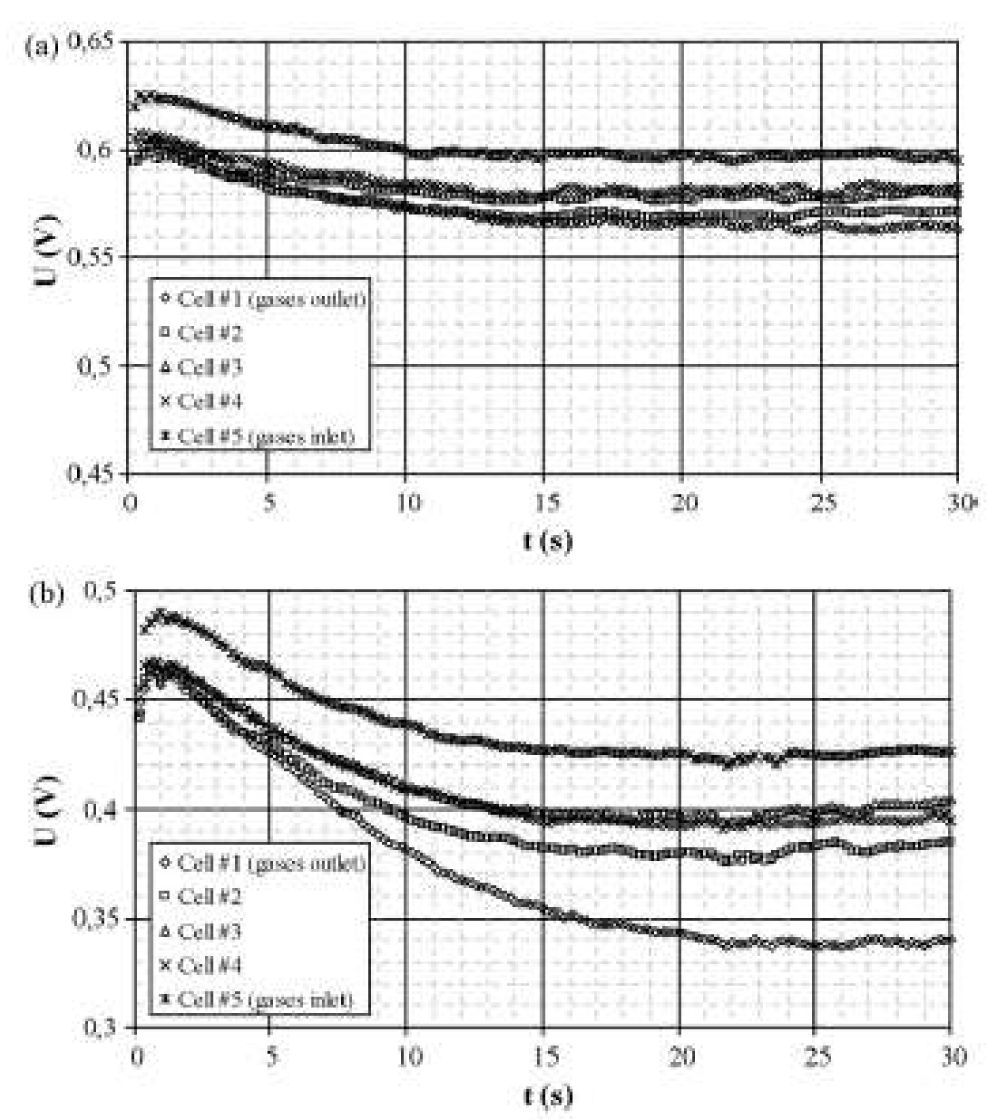

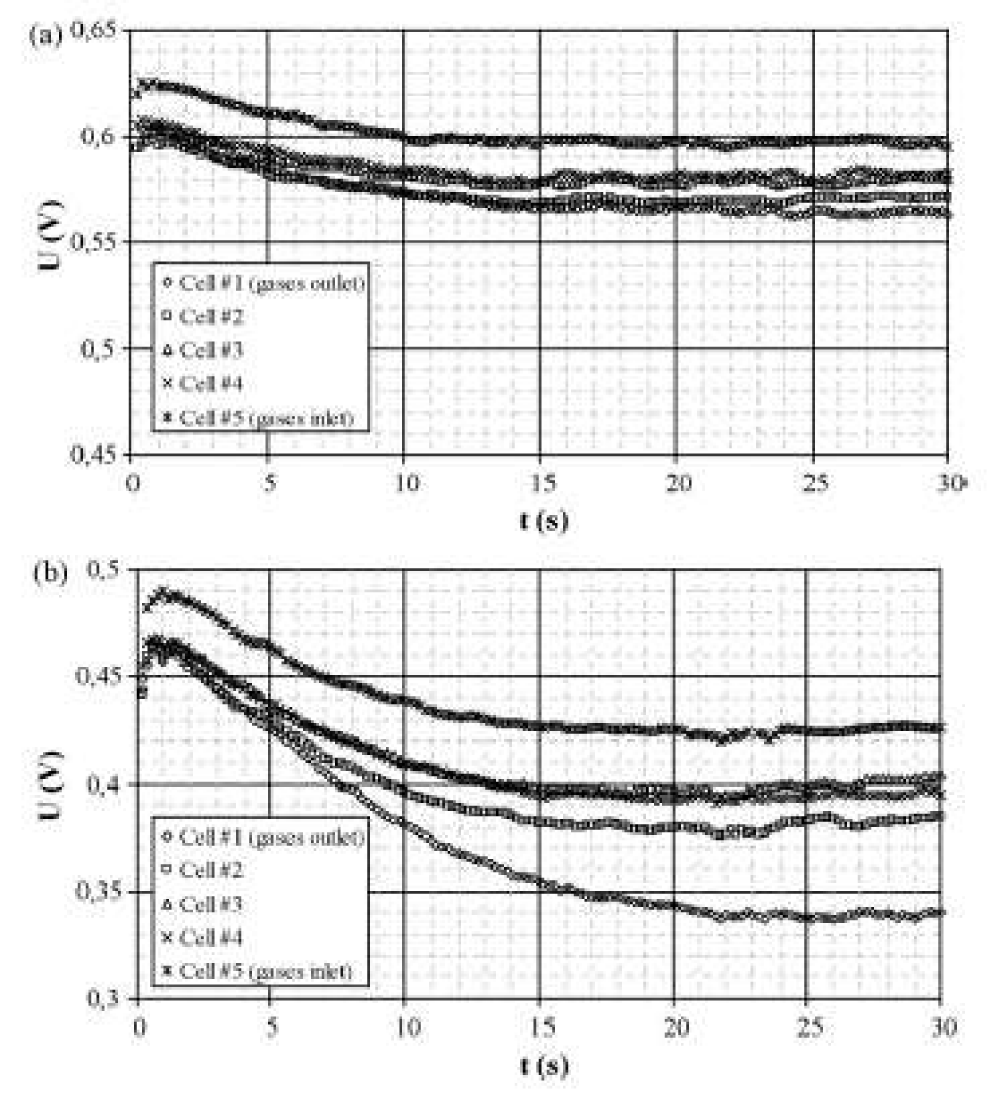

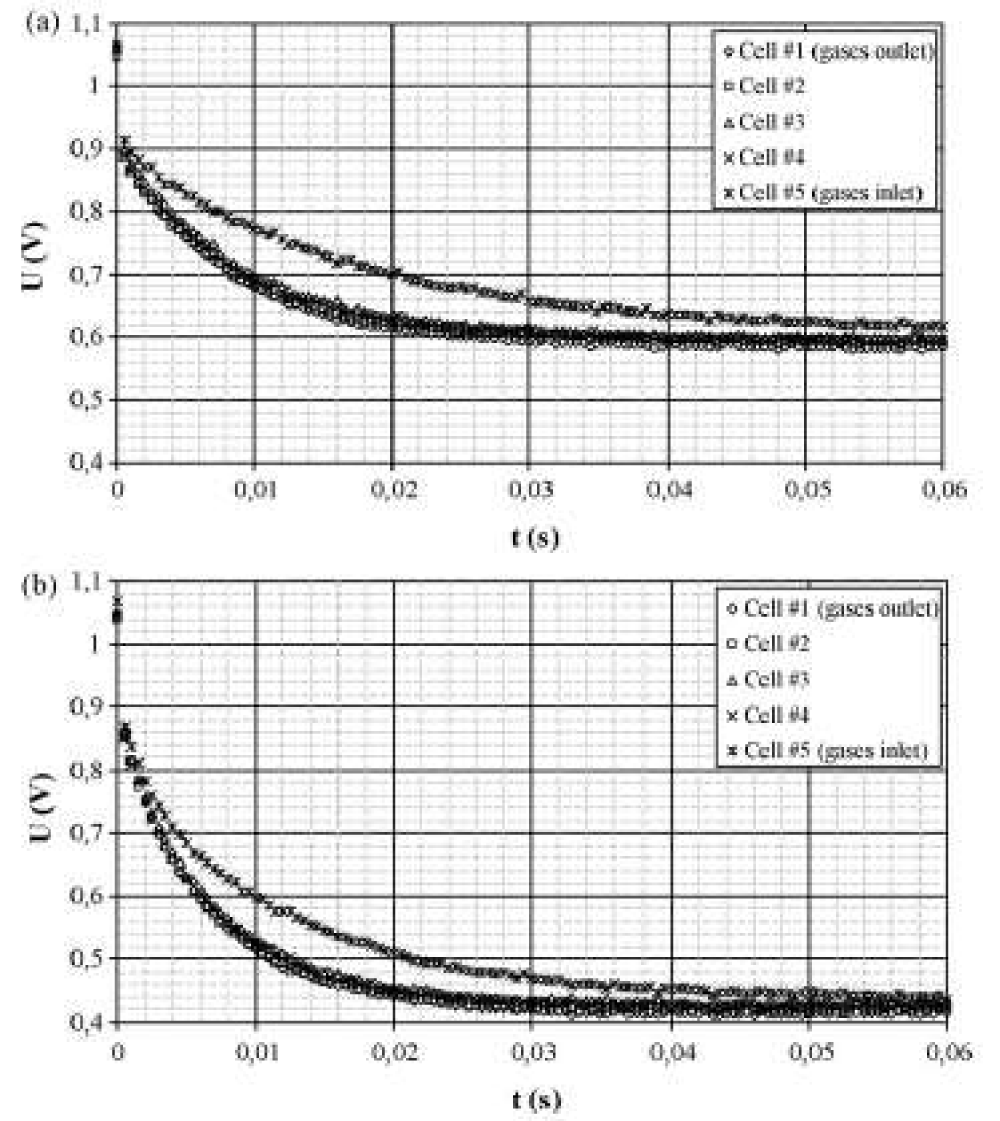

- Moçotéguy, et al. [2] used a one-dimensional dynamic model to predict to a current step (0 to 0.5 A/cm²), incorporating double-layer capacitance and water-induced porosity reduction (Eq. 3). Parameters like initial water content (s_0) and equilibrium current density (j_eq) were fitted to data from a five-cell stack (300cm², 288K) (Figure 1).

Figure 1: Evolution of each cell voltage after a current step from OCV: (a) fresh stack and (b) aged stack.

(3)

Experimental setup

- Chen, et al. measured the evolution of cell voltage and liquid water mass in a single cell with periodic purges triggered at 0.4 V, using high current (0.6 A/cm²) and 100% cathode RH to induce water accumulation.

- Moçotéguy, et al. applied a 150 A current step to a stack, recording voltages at 2000 Hz (first second) and 5Hz (1-30s), comparing fresh and aged states.

3. Analysis approach

Transient effects on efficiency, hydrogen loss, and degradation were quantified. Time constants, voltage stability, and water management strategies were compared to identify efficiency-enhancing measures.

The results are organized into two main themes: transient effects on purge optimization and dynamic responses under load changes.

Transient Effects on Purge Optimization [8].

- Purge cycle dynamics

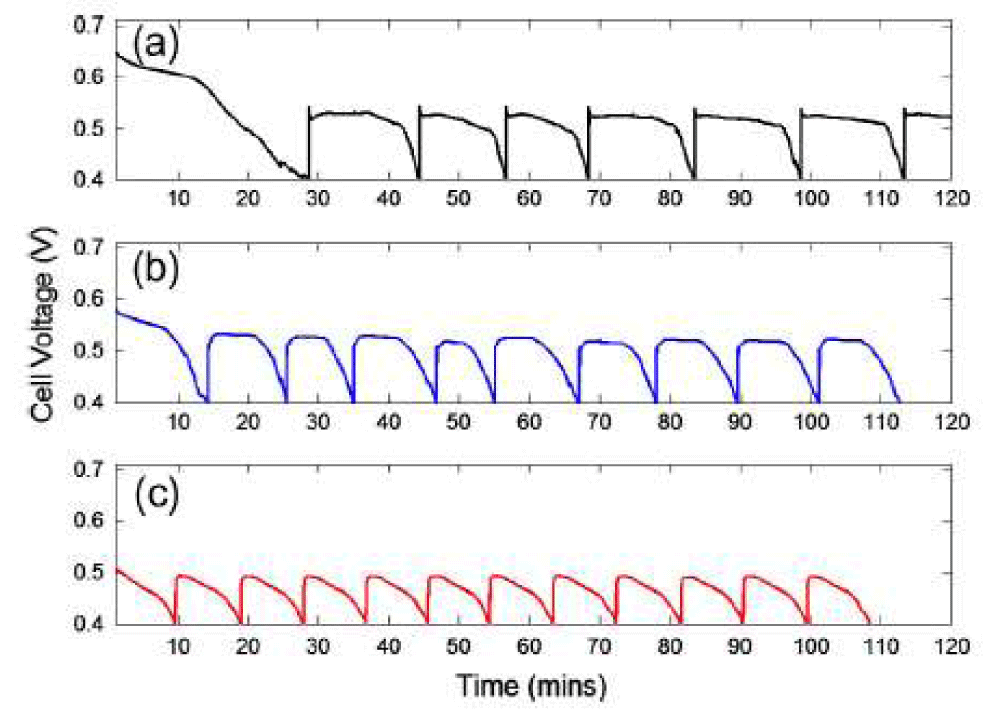

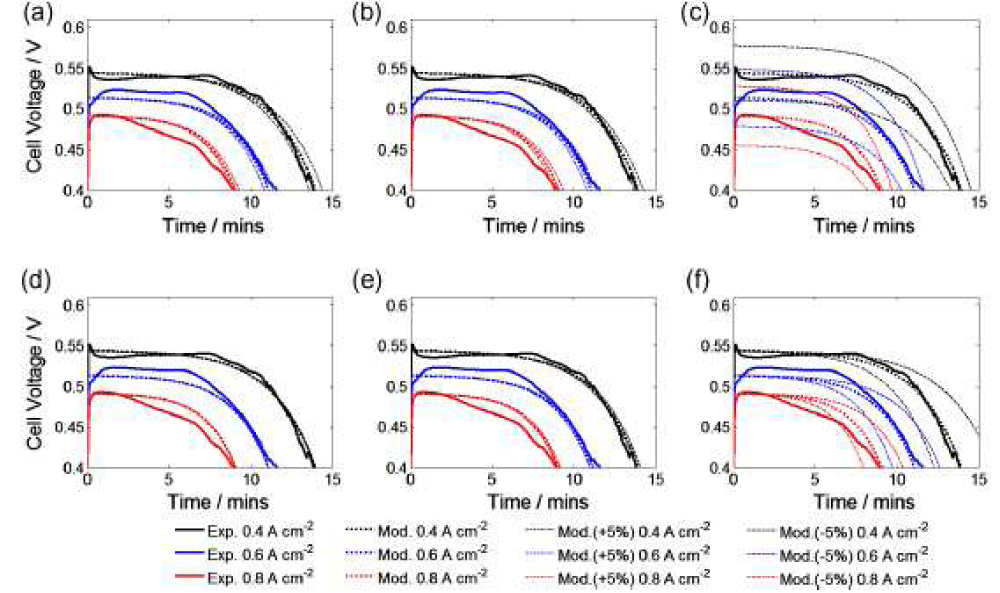

Voltage exhibited cyclic behavior with purges, dropping due to nitrogen and water buildup and recovering post-purge. Efficiency peaked within a target purge interval range (e.g., 20-54 ms for 900 s cycles) (Figure 2), declining beyond due to excessive hydrogen loss.

Figure 2: Cell voltage variations of the single cell with a dead-enabled anode operated at different constant current densities: (a) 0.4 A cm-2; (b) 0.6 A cm-2; and (c) 0.8 A cm-2 [9].

- Cycle duration impact

Short cycles (< 600 s) reduced carbon corrosion but increased hydrogen waste [10], while longer cycles (> 900 s) lowered corrosion rates after a peak cathode potential (~650 s) but reduced voltage output (Figure 3).

Figure 3: Simulation of hydrogen molar fractions on the anode side of the membrane and corresponding cell voltages at selected current densities over a defined time frame. The results highlight the impact of current density on hydrogen distribution and cell performance, providing insights into optimizing operational conditions for enhanced system efficiency [11].

- Hydrogen loss

Purge flow, modeled as plug flow [12] (Eq.2) , showed minimal hydrogen loss at the minimum interval (δt_1) and higher loss at the maximum (δt_2), affecting efficiency (Eq. 2).

- Degradation

After 150 cycles (900 s each), an irreversible 10 mV voltage drop occurred [13], linked to ~ 25% carbon loss at the channel end (Figure 4), driven by transient hydrogen starvation.

Figure 4: Sensitivity analysis of modeling parameters.

Dynamic responses under load changes [2]

- Time constants: Two responses emerged: a rapid 40 ms phase (double-layer charging) and a slower 15-20 s phase (mass transport stabilization) (Figure 5). The 40 ms response was consistent across fresh and aged stacks, while the 15-20 s phase extended with ageing.

Figure 5: Evolution of each cell voltage after a current step from OCV: (a) Fresh stack; and (b) Aged stack.

- Voltage evolution: Fresh stacks showed a 10 mV overshoot and 0.03 V cell variance, increasing to 24 mV and 0.08 V in aged stacks (Figure 6). Steady-state voltage stabilized after 15-20 s, with outlet cells lagging due to water buildup.

Figure 6: Evolution of each cell voltage after a current step from OCV: a) Fresh stack and b) Aged stack.

- Water effects: High initial water content (s_0 = 82% - 85%) rose with ageing, reducing GDL porosity and oxygen pressure (Figure 3), dropping j_eq from 110 A/m² (fresh) to 10 A/m² (aged).

- Oxygen limitation: Interfacial oxygen pressure fell rapidly (e.g., to 5×104 Pa in 7-19 s), indicating mass transfer constraints exacerbated by transient water accumulation.

The transient behavior of DEA PEMFCs reveals critical insights into efficiency optimization:

1. Purge cycle dynamics

- Chen, et al. highlight that transient accumulations of nitrogen and water drive voltage instability, necessitating purges. Optimal purge intervals (e.g., 20-54 ms) balance hydrogen retention and channel clearing, enhancing efficiency (η). However, frequent purges increase hydrogen loss, while infrequent ones risk starvation and corrosion, aligning with automotive lifetime targets (~5000 h).

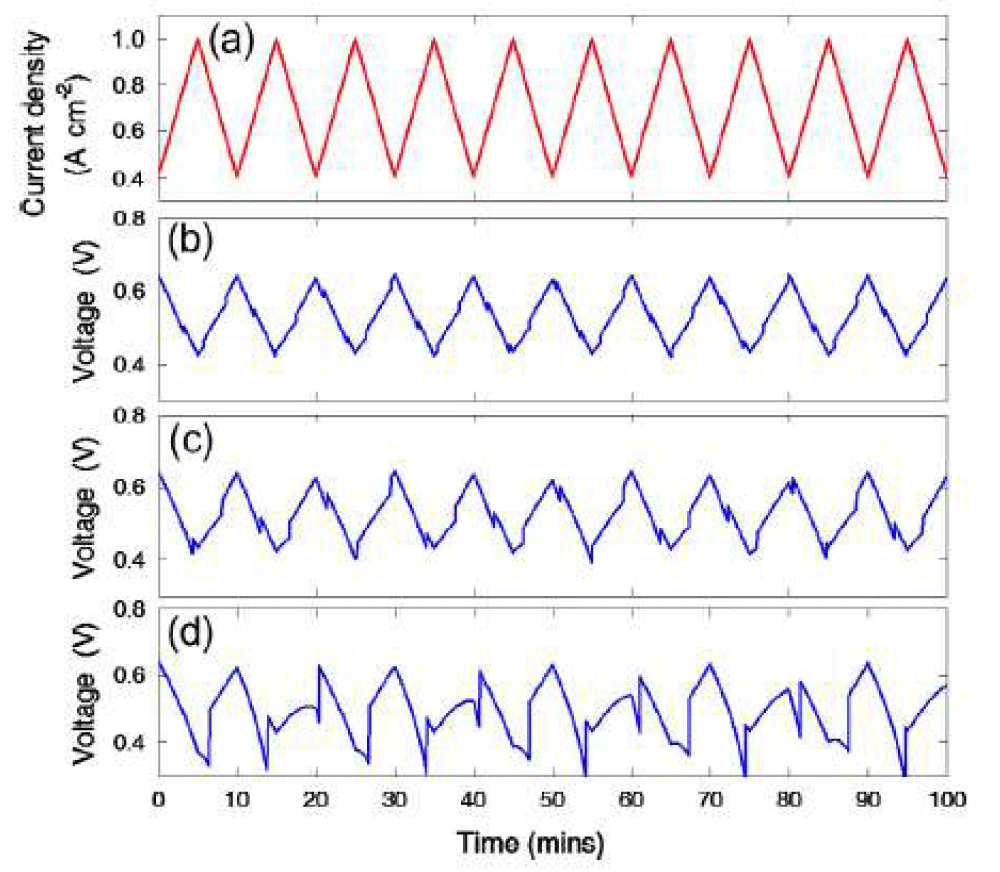

- The non-monotonic efficiency trend (Figure 7) suggests dynamic control of purge timing—adjusting intervals based on real-time voltage or gas composition—could further improve performance.

Figure 7: (a) Periodically varying current density applied to model; simulated voltage response to the varying current when the anode is purged at different nitrogen molar fractions: (b) 0.07; (c) 0.1; and (d) 0.16.

2. Transient load responses

- Moçotéguy, et al. demonstrate that rapid electrochemical responses (40 ms) are robust, but slower mass transport processes (15-20 s) are sensitive to water and ageing. This dual timescale reflects the interplay of capacitance and diffusion limitations. These factors are especially critical under transient loads, such as during startup or power surges.

- Water’s dominance in DEA mode contrasts with FTA systems, where membrane hydration is a primary concern. The high s_0 (82% - 85%) indicates flooding as the key transient challenge, reducing oxygen access and efficiency.

3. Efficiency enhancement strategies

- Chen, et al.’s purge optimization, combined with Moçotéguy, et al.’s water management insights, suggests a hybrid approach. This includes short, precise purges to clear anode accumulations, paired with cathode-side strategies like increased stoichiometric ratios for effective water removal. This could stabilize voltage and reduce corrosion.

- Ageing amplifies transient effects, increasing water content and resistance [14]. Preemptive purge adjustments in aged stacks could mitigate these losses, extending operational life.

4. Practical implications

- For DEA PEMFCs to achieve high efficiency, transient phenomena must be managed dynamically. Real-time monitoring of cell voltage or gas pressure variations, coupled with adaptive purge algorithms, could optimize efficiency under varying loads.

- The reduced need for humidification in DEA mode, owing to inherent water retention, offers a cost advantage. However, controlling flooding is a key consideration for portable and automotive systems.

Future work and research gaps

Despite the advancements reviewed in optimizing purge strategies and understanding transient responses in DEA-mode PEMFCs, several critical gaps remain that warrant focused future research:

Numerous nations are exploring future transport strategies based on the idea that electric vehicles are the future of transportation. Moreover, according to researchers, electric vehicle sales are expected to reach 45 million vehicles per year by 2040, bringing the total global electric vehicle stock to 323 million. However, there are also challenges to the future of electric vehicles. For example, battery technology has come a long way in recent years, but for larger vehicles, the power output is still not enough.

Technically, such a future is conceivable with fuel cell vehicles capable of that uses hydrogen to produce electricity. A fuel cell vehicle could act as a generator and distributor [16], and Homes could function as energy producers and refueling stations [17]. If the hydrogen and electricity produced come from renewable sources and technologies, the amount of emissions from energy consumption for your home and car could be considered zero.

Research into advanced fuel-battery technologies that uses hydrogen to power vehicles, without producing pollution, will be the achievement of competitive vehicles with higher efficiency, lower maintenance costs, and less pollution.

One of the subsets analyzed is the battery and its thermal efficiency. Different batteries tend to perform best in their own specific temperature range, so controlling temperature changes can affect the life and efficiency of the vehicle. Other important components include those that affect passenger comfort, such as heating, ventilation, cooling, and air purification, which can consume a lot of energy. NREL highlights the importance of optimizing these components to enhance passenger comfort with the least fuel consumption and pollution. This systems-level approach may reduce annual fuel consumption significantly, thereby reducing dependence on imported fuel and reducing pollution.

This investigation of DEA PEMFCs under non-steady-state conditions, reveals that efficiency can be significantly enhanced by addressing dynamic challenges. Chen, et al. [1] show that optimizing purge cycles—balancing intervals (e.g., 20-54 ms) and durations (e.g., 600-900 s)—mitigates hydrogen loss and carbon corrosion, achieving peak efficiency. Moçotéguy, et al. [2] indicate that transient responses (40 ms and 15-20 s) are governed by water accumulation, with ageing exacerbating mass transfer limitations. Effective strategies include precise purge scheduling and water management to prevent flooding, ensuring stable voltage and prolonged stack life. These findings support the viability of DEA PEMFCs, efficient alternatives to FTA systems, with future research needed to develop adaptive control systems for real-world transient operation [18].

One of the key issues of proton exchange membrane fuel cells is water management. This issue is not possible without considering the transport of liquid water within the cell. The conservation equations of mass, momentum, energy, ions, oxygen species and water vapor and the transport equation of liquid water in all layers of the cell including cathode and anode electrodes have been solved. A general study of the processes occurring in the cell has been carried out by providing contours of velocity, temperature, concentration of different species and saturation of liquid water, and the effect of liquid water on the efficiency of the cell has been considered. Also, the effect of the passage of reacting gases through the membrane on the efficiency of the cell has been investigated. The results show that by considering the effect of liquid water in the proton exchange membrane fuel cell, the polarization curve and the corresponding efficiency curve are lowered. The effects of several key variables such as coefficient of liquid water diffusion, current density, membrane thickness, and the oxygen-to-nitrogen ratio on the conditions and performance of the proton exchange membrane fuel cell, such as liquid water saturation, oxygen molar concentration, power density, cell temperature, transient efficiency, overall efficiency, potential, and ohmic potential drop, were investigated [6,19,20]. Liquid water saturation at the anode was found to be significant [21], highlighting the need for further investigation into liquid water behavior at this electrode. Liquid water saturation increased at both the cathode and anode with rising current density with increasing [22] current density.

- Wang Y, Chen KS, Mishler J, Cho SC, Adroher XC. A review of polymer electrolyte membrane fuel cells: Technology, applications, and needs on fundamental research. Appl Energy. 2011;88(4):981-1007. Available from: https://doi.org/10.1016/j.apenergy.2010.09.030

- Dumercy L, Péra M-C, Glises R, Hissel D, Hamandi S, Badin F, et al. PEFC stack operating in anodic dead end mode. Fuel Cells. 2004;4(5):352-357. Available from: https://doi.org/10.1002/fuce.200400053

- Chen J, Siegel JB, Stefanopoulou AG, Waldecker JR. Optimization of purge cycle for dead-ended anode fuel cell operation. Int J Hydrogen Energy. 2013;38(11):5092-5105. Available from: https://websites.umich.edu/~annastef/FuelCellPdf/Chen2013.pdf

- Moçotéguy P, Druart F, Bultel Y, Besse S, Rakotondrainibe A. Monodimensional modeling and experimental study of the dynamic behavior of proton exchange membrane fuel cell stack operating in dead-end mode. J Power Sources. 2007;167(2):349–357. Available from: http://philippe.mocoteguy.free.fr/Publis/JPS01.pdf

- Manokaran A, Pushpavanam S, Sridhar P, Pitchumani S. Experimental analysis of spatio-temporal behavior of anodic dead-end mode operated polymer electrolyte fuel cell. J Power Sources. 2011;196(23):9931-9938. Available from: https://doi.org/10.1016/j.jpowsour.2011.06.103

- Casadei D, Verducci F, Grimaldi A, Croci D, Palmieri A, Bianchi R, et al. Experimental investigation on the effect of channel geometry on performance heterogeneity in hydrogen PEM fuel cell. Int J Hydrogen Energy. 2024;95:1299-1315. Available from: https://doi.org/10.1016/j.ijhydene.2024.08.515

- Tsai SW, Chen YS. A mathematical model to study the energy efficiency of a proton. Appl Energy. 2017;188:151-159. Available from: https://doi.org/10.1016/j.apenergy.2016.11.128

- Chen YS, Yang CW, Lee JY. Implementation and evaluation for anode purging of a fuel cell based on nitrogen concentration. Appl Energy. 2014;113:1519-1524. Available from: https://ideas.repec.org/a/eee/appene/v113y2014icp1519-1524.html

- Yang CW, Chen YS. A mathematical model to study the performance of a proton exchange membrane fuel cell in a dead-ended anode mode. Appl Energy. 2014;130:113-121. Available from: https://ideas.repec.org/a/eee/appene/v130y2014icp113-121.html

- Boillot M, Bonnet C, Jatroudakis N, Carre P, Didierjean S, Lapicque F. Effect of gas dilution on PEM fuel cell performance and impedance response. Fuel Cells. 2006;6(1):31-37. Available from: https://doi.org/10.1002/fuce.200500101

- Yang Y, Zhang X, Guo L, Liu H. Different flow fields, operation modes and designs for proton exchange membrane fuel cells with dead-ended anode. Int J Hydrogen Energy. 2018;43(3):1769-1780. Available from: https://doi.org/10.1016/j.ijhydene.2017.10.137

- Singer G, Pertl P, Trattner A. Experiments on maximizing hydrogen utilization and efficiency in a PEM fuel cell system. Int J Hydrogen Energy. 2025;106:1158-1166. Available from: https://doi.org/10.1016/j.ijhydene.2025.02.036

- Yao J, Wu Z, Wang B, Yang Y, Yang F, Zhang Z, et al. High-stability dead-end anode proton exchange membrane fuel cells by purge optimization. J Power Sources. 2024;595:234062. Available from: https://doi.org/10.1016/j.jpowsour.2024.234062

- Mohammadi Taghiabadi M. Analysis of performance degradation in the dead-ended anode proton exchange membrane fuel cell under different load profiles. Fuel. 2024;357(Pt B):129879. Available from: https://doi.org/10.1016/j.fuel.2023.129879

- Khan N, Sagheer YA, Wilckens RS. PEFC system reactant gas supply management and anode purging strategy: An experimental approach. Energies. 2022;15(1):288. Available from: https://doi.org/10.3390/en15010288

- Pratt JW, Klebanoff LE, Munoz-Ramos K, Akhil AA, Curgus DB, Schenkman BL. Proton exchange membrane fuel cells for electrical power generation on-board commercial airplanes. Appl Energy. 2013;101:776-796. Available from: https://ui.adsabs.harvard.edu/link_gateway/2013ApEn..101..776P/doi:10.1016/j.apenergy.2012.08.003

- Oh SD, Kim KY, Oh SB, Kwak HY. Optimal operation of a 1-kW PEMFC-based CHP system for residential applications. Appl Energy. 2012;95:93-101. Available from: https://ideas.repec.org/a/eee/appene/v95y2012icp93-101.html

- Liu S, Chen T, Zhang C, Xie Y. Study on the performance of proton exchange membrane fuel cell (PEMFC) with dead-ended anode in gravity environment. Appl Energy. 2020;261:114454. Available from: https://doi.org/10.1016/j.apenergy.2019.114454

- Cao Y, El-Shorbagy MA, Dahari M, Cao DN, ElSayed MTE, Huynh PH, et al. Examining the relationship between gas channel dimensions of a polymer electrolyte membrane fuel cell with two-phase flow dynamics in a flooding situation using the volume of fluid method. Energy Rep. 2022;8:9420-9430. Available from: https://doi.org/10.1016/j.egyr.2022.07.048

- Ramesh P, Duttagupta SP. Effect of channel dimensions on micro PEM fuel cell performance using 3D modeling. Int J Renew Energy Res. 2013;3(2). Available from: https://dergipark.org.tr/en/download/article-file/148347

- Siegel JB, McKay DA, Stefanopoulou AG, Hussey DS, Jacobson DL. Measurement of liquid water accumulation in a PEMFC with dead-ended anode. J Electrochem Soc. 2008;155(11):B1168-1178. Available from: http://dx.doi.org/10.1149/1.2976356

- Lee Y, Kim B, Kim Y. An experimental study on water transport through the membrane of a PEFC operating in the dead-end mode. Int J Hydrogen Energy. 2009;34(17):7768-7779. Available from: http://dx.doi.org/10.1016/j.ijhydene.2009.07.010