More Information

Submitted: January 03, 2024 | Approved: January 22, 2024 | Published: January 23, 2024

How to cite this article: Pratt J. Management and use of Ash in Britain from the Prehistoric to the Present: Some implications for its Preservation. Ann Civil Environ Eng. 2024; 8: 001-011.

DOI: 10.29328/journal.acee.1001059

Copyright License: © 2024 Pratt J. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Management and use of Ash in Britain from the Prehistoric to the Present: Some implications for its Preservation

Jim Pratt*

Cross House, Mountain Cross, West Linton, Peeblesshire, EH46 7DF, Scotland

*Address for Correspondence: Jim Pratt, Cross House, Mountain Cross, West Linton, Peeblesshire, EH46 7DF, Scotland, Email: [email protected]

The properties that make the wood of fast-grown Ash pliable, strong, and resilient have been exploited by man for thousands of years, and are illustrated by reference to the probable use of Ash timber for tools, arms, and transport by the Roman Army of Occupation in Britain two thousand years ago. Militarily organized and disciplined, the Roman Army was responsible for changing the face of Britain with huge infrastructure projects that required significant numbers of tools, equipment, and fuel, in addition to the arms it used to maintain control over the fractious tribes of the north. The extent to which it maintained supplies of this valuable resource by managing its woods, possibly by coppicing, is discussed and raises the question as to the degree of genetic selection involved in coppicing.

Ash: Fraxinus excelsior: extinction: prehistoric and historic uses: Roman army military use of Ash.

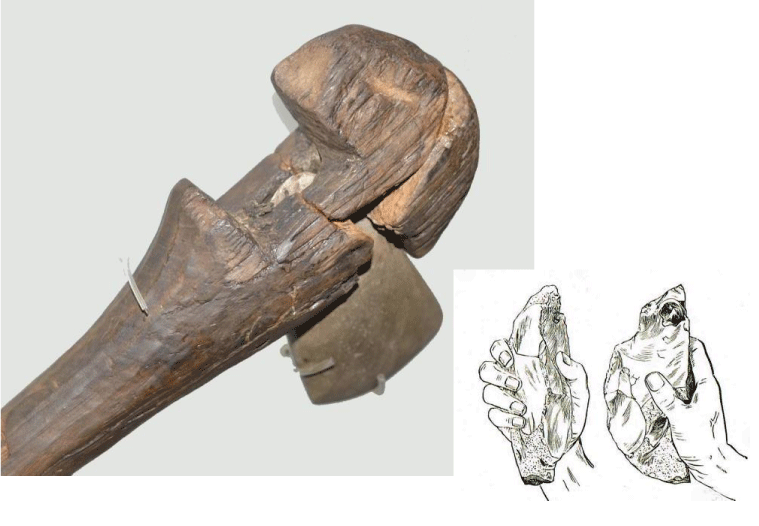

Arguably, one of the most significant of man's achievements has been to work out how to fix a handle, or haft, to a stone and thus create an axe. This is a surprisingly difficult union to achieve using only stone tools, and early man exhibited great ingenuity in doing so, even to the extent of using pieces of antler as intermediate links between wood and stone [1]. The effect of the haft is to extend the radius of a man’s arm, thus trebling the length of the arc of travel of the axe head and thereby increasing the speed of the stroke. By doubling the speed of travel of the axe head the force of impact is quadrupled [2]. The provision of this significant mechanical advantage over hand-held axes enabled man to extend his lifestyle beyond that of a hunter-gatherer and manage his environment to provide a regular source of food and heat. Although stone axe heads are commonplace, few hafts have survived, and there is no clear date for this crucial invention. One exception is the Shulishader porcellanite stone axe from the Hebrides (Figure 1) which has a haft tentatively identified as Rosaceae sp. The fact that this haft seems to have been reused suggests the value placed on a good handle. Ash, (Fraxinus excelsior L) which became the preferred timber to use in wooden hafts [1,3,4], was uncommon in North Britain when this axe was made in the Neolithic: a C14 date of 3495-2910 BC [5] for the handle fits with a known period of use of porcellanite stone axe heads imported from Northern Ireland [6].

Figure 1: Neolithic Stone Axe, found at Shulishader, Lew- is. The haft is probably Rosaceae spp. The head, from Ireland, is porcella- nite. The axe is in the Na- tional Museum of Scot- land, Edinburgh and the photograph is reproduced with their permission. Stone hand axes were man’s only large tool for hundreds of thousands of years.

Although no wooden axe hafts have been found from the early Palaeolithic, there is clear evidence that by at least 60,000 years ago early humans already had a long history of making wooden handles and shafts for their stone tools, bound together with tree resins [7]. These included shafts for spears made by Neanderthals 400,000 years ago [8]. Although these shafts were of spruce, they provided precedence for all that followed. Later there is clear evidence (see below) that Ash had become the preferred species for spear shafts. What are the characteristics of Ash that make it so suitable for this purpose?

Ash timber properties

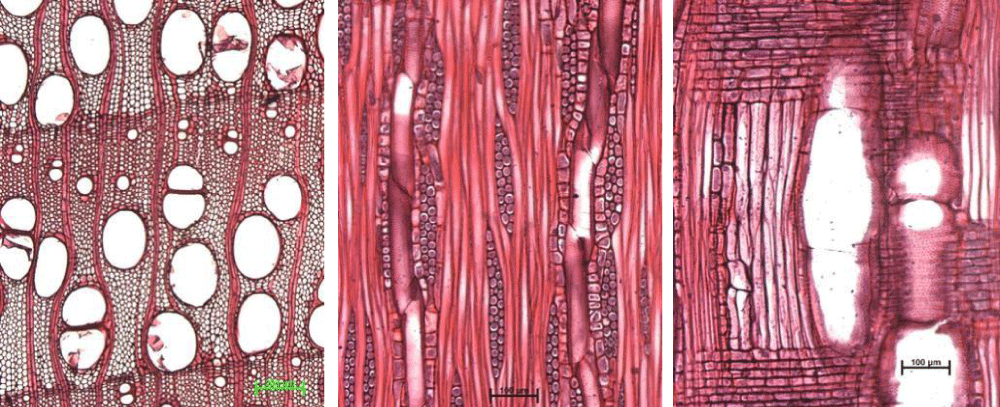

Ash is a ring-porous fast-growing native hardwood. It is easy to saw and machine when dry and is the toughest of British-grown woods [9]. It has vasicentric axial parenchyma, i.e., a complete sheath of parenchyma cells around one or more vessels (Figure 2). Over several years’ radial growth, the thickness of early wood remains fairly constant and any increase in ring width comes from the laying down of more latewood vessels, with a corresponding increase in density. Strength and toughness will therefore tend to increase with more rapid growth. Weaknesses in slow-grown Ash can be explained by the comparatively narrow layers of latewood that are laid down where short growing seasons restrict the amount of latewood formed.

Figure 2: Anatomy of Fraxinus excelsior (Ash) . From left: cross (xs), radial longitudinal (rls) and radial tangential (tls) sections. Courtesy Peter Gasson, Kew.

Variability of growth also depends on genetic or systematic effects: ring width tends to reduce with increasing age, so timber derived from old trees may be less dense and not as tough as that from young vigorous trees. Ash has an air-dry density close to that of both oak and beech (650 - 700 kg/m3), and a high Modulus of Elasticity (longitudinal: 15,800 N/mm2, radial 1510 N/mm2) compared to other hardwoods [10]. Toughness (the resistance of wood to the propagation of cracks on sudden impact) is an essential characteristic of woods used for handles, of which Ash is a notable example. High density is a prerequisite of this strength property, as is the fibre-composite structure where relatively weak interfaces between cell-wall layers absorb energy by modifying (redirecting) the primary crack [11]. Timber of low density, the presence of compression wood, and other growth imperfections can all reduce toughness. In the case of Ash for tool handles, it is now recommended that wood having between 4 and 16 rings per 25 mm should be used to avoid serious injury that can occur from failure of slow-grown stems [10].

Ash is also notable for its bending properties, which depend on its structure, toughness, and strength. Standard tests in which clear specimens of constant (25.4 mm) thickness were subjected to bending to failure show how well Ash compared to other native species (Table 1). Comparison is also drawn with two commercially-important North American species. Tests were undertaken in which the outer 'tensile' face was supported either with or without a restraining strap, the latter being indicative of the bending undertaken in normal use.

Table 1: Limiting radii of curvature (mm) at which 5% of the population of test samples of home-grown species failed in steam bending following air-drying. (m/c not given). Data from Stevens and Turner (1970). |

||

| Species | mm (supported) |

mm (unsupported) |

| Ash | 64 | 300 |

| Alder | 360 | 480 |

| Beech | 38 | 330 |

| Elm | 38 | 340 |

| Hornbeam | 100 | 420 |

| Oak (Q. robur) | 51 | 330 |

| Yew | 220 | 420 |

| Hickory (USA) | 46 | 380 |

| Sitka spruce (home- grown) |

910 | 810 |

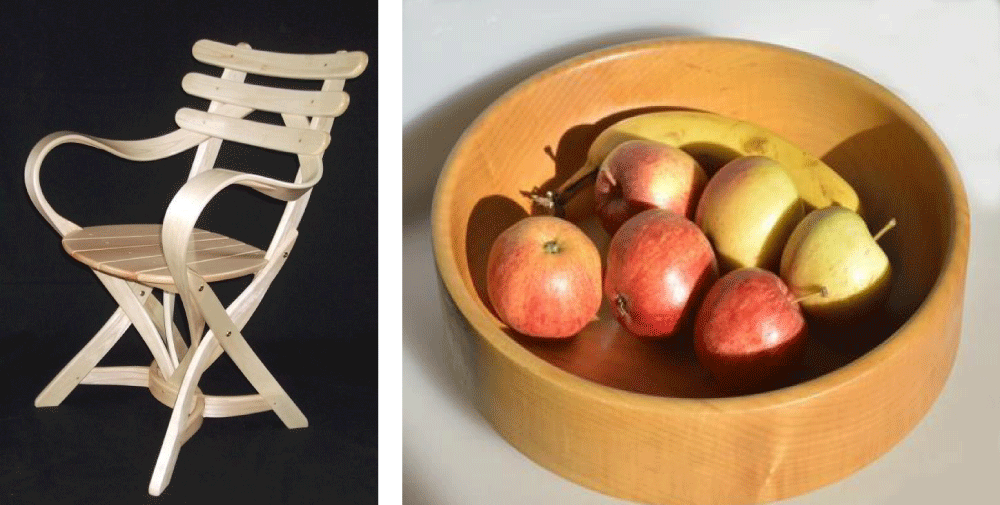

Ash is clearly superior in unsupported bending to all these species, albeit beech and oak are perhaps more adaptable. In thin-section (3.2 mm) laminates, Ash is superior to all except beech. It is easy to work, and produces few splinters. It turns well and makes strong, light furniture with a pleasing honey-coloured grain (Figure 3). Its many domestic uses have been rehearsed recently [12,13]. Ash has long played a part in conflict (see below) and recently in two world wars (Figure 5)

Figure 3: Coppiced Ash split from an ancient stool in Bradfield Woods and bent to form this chair, made by a local craftsman Dan Hussey, who kindly donated this photo- graph. Ash turns well.

Figure 4: Replica 1911 Bristol Boxkite, built by Miles Aircraft Ltd for the film “Those Magnifi- cent Men in their Flying Machines” using authentic materials, which included Ash for the undercarriage skids. 6 May 1964, pilot George Miles FRAeS. Photo courtesy Karen Miles.

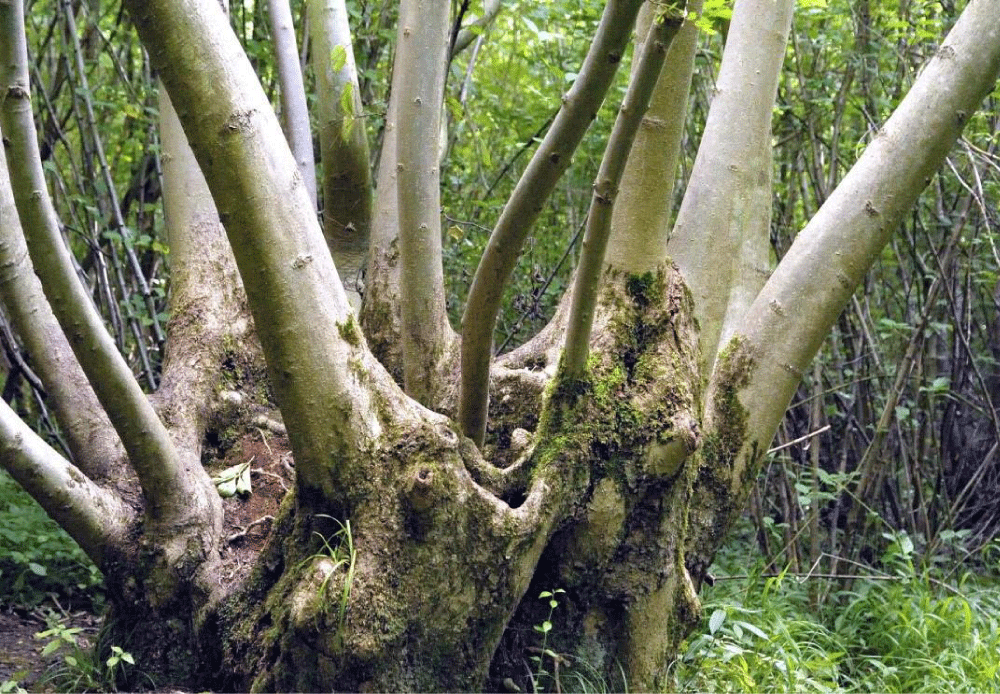

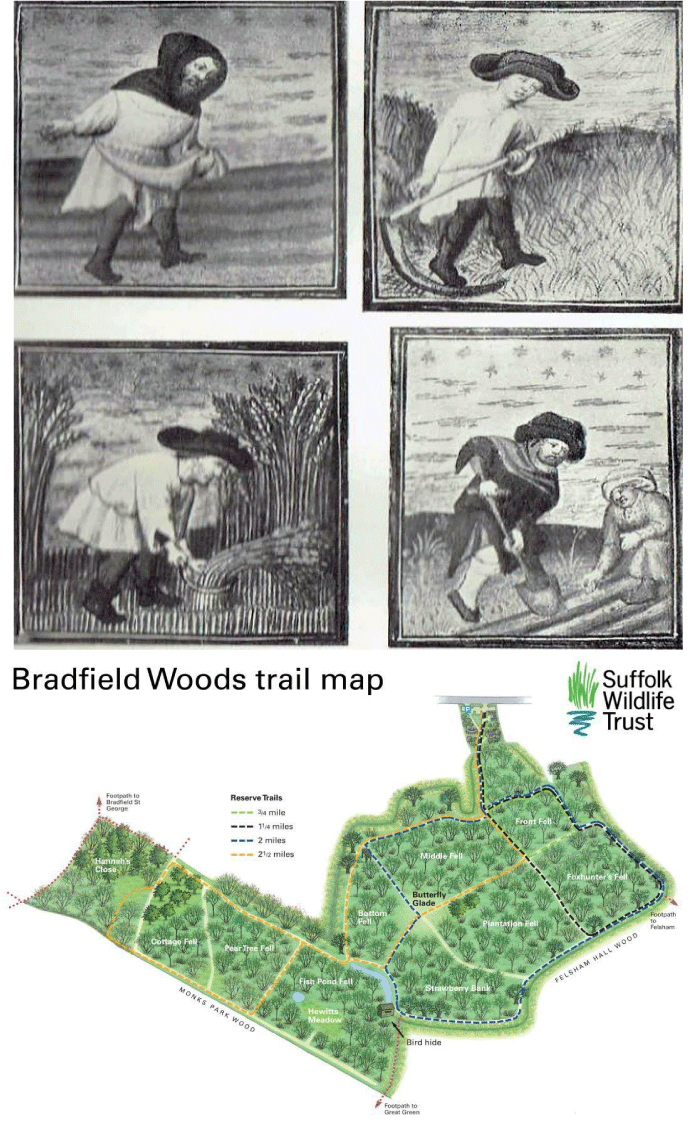

Figure 5: Coppiced Ash stool, Bradfield Woods, Suffolk. Some of these stools are 800 years old and may have been cut at least 70 times. Note the high quality and vigour of these stems.

when it formed the undercarriage skids on the Bristol Boxkite, used as a trainer in WW1, and in WW2 formed part of the wooden structure of the De Havilland Mosquito, adding strength to wooden components in areas of high stress.

Ash management, Britain

Ash grows widely throughout Britain, performing best on deep, moist well-drained brown earths where Yield Classes 10 – 12 have been recorded [14]. Form is likely to be better in mixed than in pure stands. Hiley concentrated on growing Ash for the lucrative sports industry in south Devon [15], and found it surprisingly hard to achieve consistently superior crops, noting that there is much to learn about the species. However, he quotes correspondence in which sales of high-quality timber were sporadic until the First World War, when the circumstances changed dramatically so that demand for the same timber from the Bristol Aeroplane Company outstripped supply.

Management of Ash by pollarding, to provide foliage as livestock feedstuff, was commonly practised over centuries [12]. Of more significance is the management of Ash by coppicing. Rackham noted that in rural communities, Ash grows faster in coppice than as planted trees, and the resultant poles are more useful than the big tree. He suggested [16], from evidence collected from excavated Neolithic trackways in Somerset that coppicing started 6000 years ago. It is now clear that this form of management began much earlier [17], since evidence similar to that found in Somerset for coppicing has been found on Mesolithic sites in Yorkshire to date from circa 9000BC - 7000BC, and from submerged landscapes on the edge of the English Channel [18]. By the time when farming was developing in the Neolithic in the third millennium BC, coppicing to produce a strong, resilient timber of useful and consistent size, easily harvested using simple stone tools [19] and gathered from close-by, was therefore already well established. Its use was not confined to Britain, and has been inferred from pollen and wooden artefacts from Switzerland in the early Neolithic [20]. Direct evidence for coppicing other than that inferred from the shape of preserved artefacts in the prehistoric period is circumstantial at best, and no diagnostic features distinctive of coppice have been found on the ground. An added complication is that Ash is rarely common within pollen diagrams [21]. However, references of the use of coppicing per se are not uncommon among Roman authors [22]. That Ash was coppiced in the Middle Ages is not in doubt [23], and it is readily observable today in, for example, Bradfield Woods, Suffolk, (Figure 5) where some of the coppice stools are amongst the oldest living objects in Britain.

The Ash in antiquity

Ash was the chosen wood for one of the oldest anthropomorphic carved figures in Europe, found in the Somerset Levels and dated to 2100 BC [24]. It may be relevant that it is considered to be hermaphrodite [25]: apposite for a triecious species such as Ash [26].

In Viking mythology, Yggdrasil was a gigantic Ash that bestrode the world and heaven, with its roots in the underworld. It joined together the lands of gods and men. Its huge size and shape was strong enough to hold them apart yet keep them together in one place. It was a world of good and evil, of joy and sorrow, and it suffered more than man can understand. Yet from this vast and terrifying object, the bees feed happily on its honey dew [27]. Rivers that flowed from its three roots gave rise to the ancient association between Ash trees and sources of water such as wells and springs, and is one of the reasons why Ash occurs commonly in English place names (see below).

Ash had more mundane uses in Medieval England [28]: to remove warts (in Cheshire), you were advised to rub them with bacon and slip the bacon under the bark of an Ash tree Figure 6. In addition, an anti-malarial tonic was extracted from Ash bark before quinine was introduced to Europe (Lonsdale, D.L. pers. comm. 2016). Ash also had a special function curing rickets or rupture: a longitudinal split made in a tree was opened up, and the affected child, naked, would be passed through the fissure at sunrise at least three times. Thereafter, the split would be closed, tightly bound and sealed with clay. If the tree should die, then so would the patient, who (unsurprisingly) guarded the tree assiduously for the rest of his life. This personal attachment to Ash trees may be another reason why the name occurs with unusually high frequency among English place-names [23]: another is the utilitarian value of the species to rural communities for the provision of small-wood and building timber, fuel, fodder and implements.

Figure 6: Medieval husbandry re- lied on hand-held implements for almost all the work needed to keep body and soul alive. Brad- field Woods, in Suffolk, England (below) has been a source of sup- ply of coppiced Ash for at least 1000 years, the long, clear stems being used locally to make hay rakes, scythe handles and fine bent furniture. The woods are di- vided into at least ten sections, to ensure a range of ages for con- tinuous coppicing. Map courtesy Suffolk Wildlife Trust.

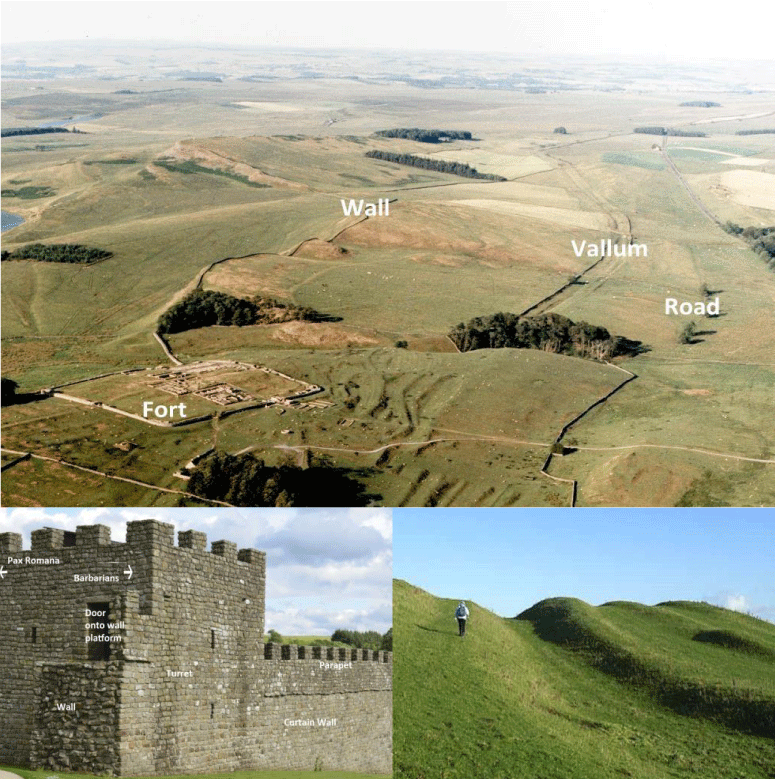

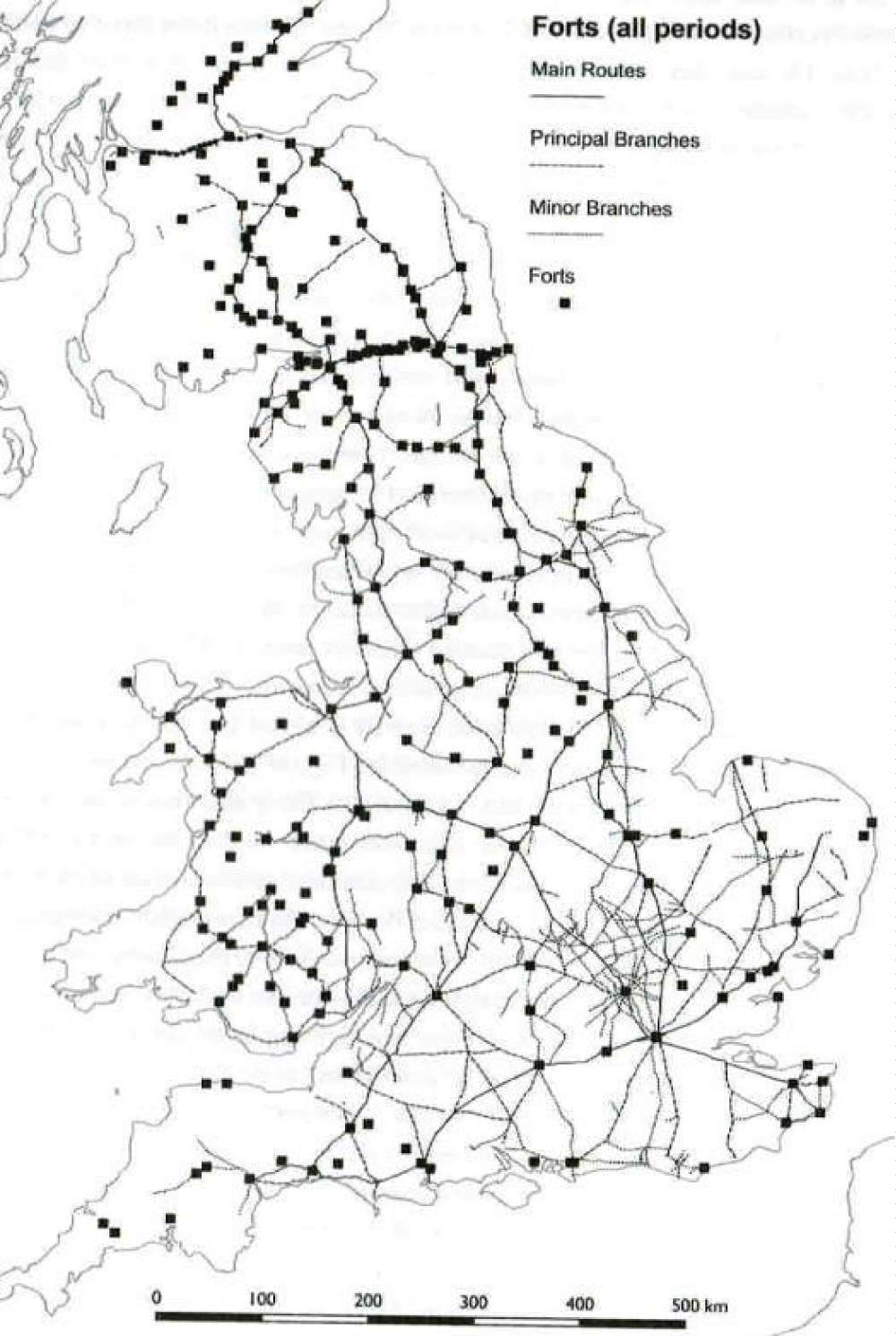

This utilitarian value of Ash is considered below in relation to the demands for wooden artefacts (particularly weapons and tool handles) in one well-researched group from the Iron Age, namely the Imperial Roman Army which occupied Britain for 350 years from AD 43. Within the first 80 years this highly-disciplined force built major infrastructures within a relatively undeveloped, rural Britain, often to standard design. They included over 2000km of permanent, all-weather roads [29], hundreds of bridges, 300 military forts, 6 major fortresses [30], and the 118 km (72 mile) frontier system, Hadrian’s Wall (Figure 7). 20 major urban towns were constructed during that period [31]. For a discussion on the post- conquest surveying of road alignments, see Current Archaeology (Issue 314) May 2016.

Figure 7: The northern Frontier of Roman Britain. Aerial view East over the Roman fort of Housesteads, on Hadrian's wall. The curtain wall lies along the north wall of the fort and stretches to the horizon. The Vallum runs almost parallel to the Wall itself and forms the southern edge of the militarised zone. To the south of the Vallum, the (later) Roman military road joining all the forts on the wall is evident in this aerial photograph. (Photograph by kind permission of Air Images Ltd). A reconstructed turret at Vindolanda Roman Fort attached to a short length of the curtain wall illustrates around 30m of the 117 km frontier that makes up Hadrian’s Wall. The massive earth-moving needed to create the 112 km length of the Vallum is evident in the insert below right, all the more impressive when it is realised that it was dug by hand using dolabra, wooden shovels tipped with iron, and moved in baskets and carts.

The Army that invaded Britain in 43 AD was composed of four legions each of 5,000 heavily-armed infantrymen with a roughly equivalent number of Auxiliary troops, the latter raised in European countries that had been absorbed into the empire. This Army crossed the English Channel in around 900 ships [32] and was a self- contained expeditionary force with horses, wagons and carts, tents, weapons, building tools and enough food and fodder for several days campaigning. It established a defended base near London from which it fanned out into the country probably using existing trackways [33], each legion and its auxiliary vexilations subduing its allotted zone. Although Britain was a land without permanent roads or bridges, in which most of the inhabitants were involved in agriculture, it was a sophisticated tribal culture with a population estimated to be between two and four million people [34], of which the majority (>90%) were rural agriculturalists [35]. Close ties with Europe gave the south-east of the country easy access to the Roman Empire, and the tribes that lived in that area were, for the most part, sympathetic to Rome and indeed some may have welcomed and aided the invasion.

Further north and west, away from the continental influence, the native peoples were not compliant and a large, permanent Roman garrison was required to contain them. Thus, three legions (15,000 men), along with 35,000 Auxiliaries remained in Britain throughout the occupation [36]: Spain, by contrast, took 100 years to subjugate but was thereafter controlled by one legion.

The tools and equipment of the legions have survived in sufficient numbers to show their diversity. Their techniques of working are well illustrated in relief carving in stone (Trajan’s Column in Rome, dedicated stone slabs and altars, etc.), and are clearly evident as solid remains in many archaeological excavations in Britain. Indeed, more is probably known of the Roman Army than of other military units in Britain up to the 18th century. One of the sources of that information comes from a significant assemblage of finely-preserved military artefacts which was found in an abandoned second-century fort, Trimontium, at Newstead in the Scottish Borders when it was excavated 100 years ago. The photographs from the excavation report [37] show how self-reliant the occupants of this (and of other) forts must have been, capable of manufacturing, repairing and refitting tools, weapons and equipment in wood, metal, leather and fabric in dedicated workshops (fabricae), [38] within the forts, and illustrate the advantages of Roman military self- sufficiency admired by contemporary writers (Vegetius, 4th Century AD) Figure 8.

Figure 8: Distribution of Roman Army forts built in Britain AD 43—AD 404. Note the concentration of forts in the north and west of the country, and the network of main roads which were built by the Roman administration. Map reproduced, by kind permission of Dr M.C. Bishop from his book The Secret History of the Roman Roads of Britain.

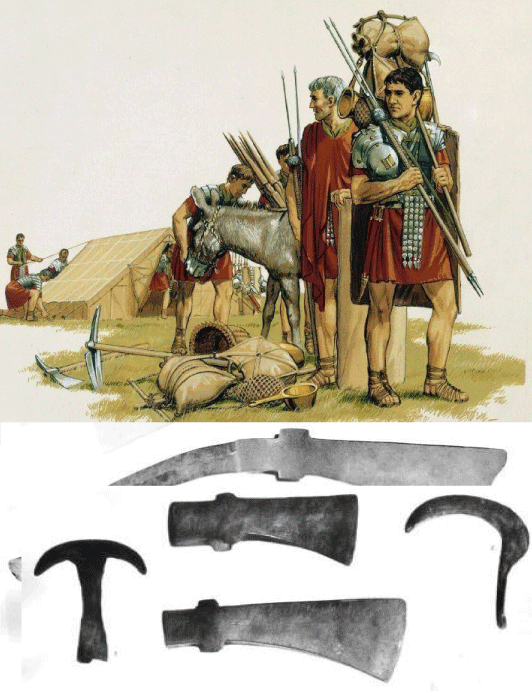

The legions were self-sufficient partly because each man carried all the tools and equipment needed to march, fight, sleep, feed and build; clearly illustrated in Figure 9 showing the members of a ‘section’ of eight men who operated as a unit (contubernium), sharing a tent carried by a pack animal. In addition to his arms and armour, each man is recorded as carrying a saw, basket, pickaxe, a thong of leather, a hook, and three days ration: a bronze mess-tin and a kettle completed the kit, hung on a staff carried on the left shoulder [39]. The arms consisted of a pair of javelin (pila) and a short-sword. Attached to the staff was a wooden stake, sharpened at each end with a hand-grip in the centre, known as a palisade stake (pilum murale), thought to provide a temporary defensive rampart on the march.

Figure 9: An eight-man “section” (contubernium) in a Roman legion prepare to move, in a drawing by Peter Connolly. Each man will carry his own equipment slung on a pole over his left shoulder. Note the two pila in his right hand. The equipment of the second man in line is lying on the ground. The leather 8-man tent will be carried by the donkey. Note the bundle of palisade stakes on the donkey. This picture is taken from The Roman Army by Peter Connolly (Macdonald 1967). Image courtesy akg-images / Peter Connolly 2016. Insert: examples of dolabra , axes, a reaping hook and a turf cutter found during the 1910 excavation of the Roman fort at Trimontium in South Scotland.

The auxiliaries were less encumbered than the legionaries, and were armed and protected according to the custom of the area from which they came. In general, each man carried a sword and also a spear, the latter a weapon distinct in form and function from the pila of the legions. The spear was a weapon for close-order fighting, and not for throwing. Ash has been the preferred haft for spears for thousands of years [40,41]: in ancient Greece, (and indeed also in Wales) the words for spear and Ash are collocations: Homer has spears as always “ashen”. Many hundreds of thousands of spear hafts would have been in use within the Roman Army of occupation, the hafts being the disposable part of the weapon. Evidence that the spear heads were valued and recycled comes from a chest of metal Roman military equipment excavated at the Roman military supply base at Corbridge, on Hadrian’s Wall [38]. Along with armour needing repair were a number of spearheads with broken shafts, supposedly of Ash [42]. Spear shafts could quickly be made from slender stems of coppiced Ash.

In contrast to the auxiliaries’ spears, the primary weapon of the legionaries was the pilum, of which each man carried two. This was a close-range javelin that used weight to provide its penetrative power, especially against armour [38]. A sharpened four-sided steel bodkin head was made at the end of a soft-metal shank, perhaps 500mm long, which in turn was riveted to the end of a weighted haft 1500 mm long. At the base of the haft was a pointed metal shoe or butt, so that the weapon could be stood on end when not carried. This was a subtle weapon, particular to the Romans and well suited for use against barbarians whose natural defence to it was to raise the shield and intercept its flight. Herein lay its inherent effectiveness, since the pilum would readily pierce most shields, and its soft-metal shank would bend under the weight of the haft, rendering the shield useless and exposing barbarian flesh to the brutal Roman stabbing short-sword (gladius). As with the spear, it is probable that Ash was the preferred material for the haft, but unlike the spear the haft was a complex engineered component of value in itself. Many hundreds of thousands of these weapons would have been brought over in the invasion of 43 AD, and the weapon remained standard issue throughout the occupation. It seems likely that coppiced Ash would have been an efficient local source of supply for this weapon as well as for the spear. Key to its effectiveness was the accuracy with which it could be thrown, and the straightness of the haft was crucial. Access to a constant supply of straight stems from which the hafts could be fashioned would be a distinct advantage, and coppiced Ash the ideal choice.

Other weapons made from wood included bows and arrows, and artillery. Most formations included some bowmen, mostly from the Middle East. They used composite bows, made from horn and a variety of woods which did not seem to include Ash. Few bows survive entire. Arrows were made from many woods, of which Ash and pine are specifically mentioned [38]. The mobile artillery (ballista and catapulta), carried or mounted on carts, consisted of frames, mostly oak, with tensionable arms that could have been made from Ash. They shot sturdy wooden-shafted bolts, often of Ash, or stones. They are relevant because of the use of carts (see below). Each legion was equipped with 60 cart-mounted ballista and ten catapulta, each with a supporting cart carrying the ammunition [32], making 140 carts for the artillery alone.

Among the many tools with which legionaries would have been familiar are two that relied on strong hafts: axes and pickaxes (dolabra). Axes (Figure 10) indicate the reliance the Roman military placed on the working of timber. Their commitment and skill working in wood is exemplified in the speed with which the navy was capable of building large (>40 m long) sea-going wooden ships. The Roman author Livy noted that in 205 BC they built 30 of these ships, capable of carrying 10,000 men, from cutting timber to launching in 45 days [43]. On land, the use of timber was equally impressive. An “average” fort for 1000 troops, built during the pacification of Wales in the first century [44], Pen Llystyn covered an area of 1.6 ha with a rampart length of 520 m. The external gates and watch towers along with ten barrack blocks, headquarters, workshops and hospital buildings and two granaries within the rampart were built and roofed of timber, the majority probably of oak [45]. Assuming sizes of timber squared from logs 30 cm in diameter for the structural uprights, along with an allowance for roofing material, it is estimated that around 1000 tonnes of logs would be needed, obtained from some 2000 medium-sized trees. The harvesting, transport and preparation of these timbers was done with hand-held tools, of which the axe would have been predominant. However, the axe (Figure 10) has some curious features. It is large by modern standards (250 mm long, 2.7 kg), of sophisticated construction and yet the eye (to contain the handle) is very small, presupposing a very narrow, round haft. Clearly, a very strong timber would be needed to counteract the considerable force exerted on the haft at its junction with the eye unless the haft was strengthened with a metal collar of some kind, and there is no evidence for that. The fort at Pen Llystyn is one of some 300 built in Britain (Figure 11): some are smaller and a few are very much larger. A 22 ha legionary fortress for 5000 troops of about the same date, at Inchtuthil in north Scotland is estimated to have required some 16,200 cu m of timber, derived from at least 60,000 trees for its construction [46].

Figure 10: A Roman army axe from Trimontium fort, south Scotland. This axe was made by a skilled artisan. It is 250mm long and weighs 2.7kg. The eye is approx. 40mm long: in a modern axe of this weight it would be at least 70mm. The axe is in the National Museum of Scotland, Edinburgh and the photograph is reproduced with their kind permission.

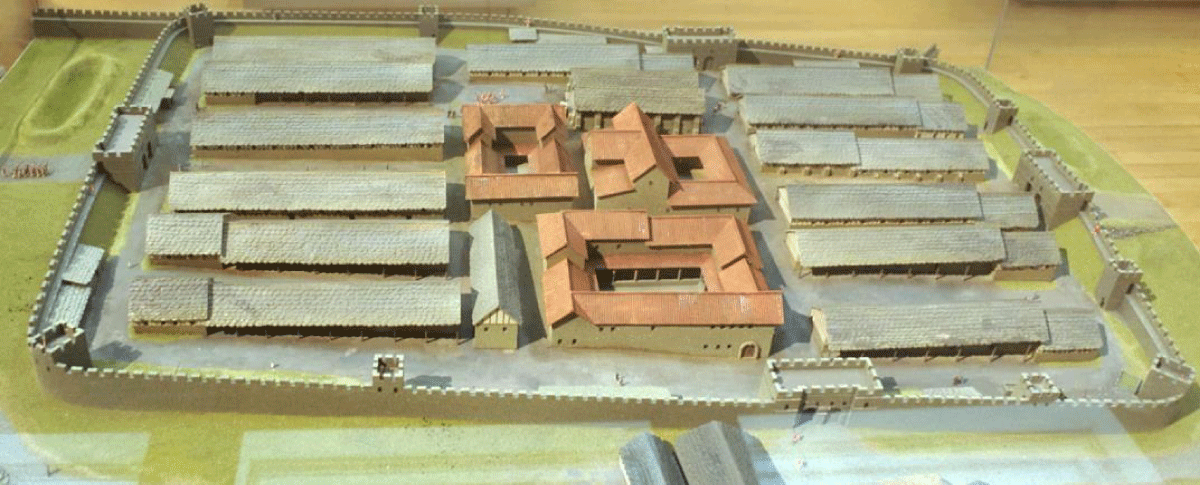

Figure 11: Table-top model of typical Roman Army fort, probably 2nd century, built of stone. Similar in size and layout to the earlier wooden fort at Pen Llystyn, with a perimeter of around 500m, an area of 1.6ha and accommodation for up to 1000 troops.

So far, I have considered the need for high-quality wooden hafts on the tools used for working timber into shapes suitable for building. It is appropriate at this point to consider also the source of the building timber itself. The sheer volumes would contradict the views of earlier archaeologists that many of these buildings were prefabricated out of stockpiled seasoned timber [47], and there is general agreement that structural timber was sourced locally. Additionally, great use was made in these buildings and their associated defences of wood of small diameter for the construction of woven panels to support clay or plaster walls or turf revetments. It has been estimated that in the 1.6 ha wooden fort at Carlisle, in northern England, some 50,000 poles or rods would have been needed for the six barrack blocks, let alone all the other structures and the ramparts [22]. This material would probably have been sourced from pre-existing managed coppice woodland, created by local people to supply building materials and fuel. The large quantities of timber required for this and all the other forts that were constructed of wood along the northern frontier might indicate that the local timber resource was unlimited. In practice, this seems not to have been the case, as is shown by the inappropriate use of Alder timber in structural components of an early Roman fort [48]. Analysis of tree pollen from around the line of Hadrian’s Wall during the early part of the Roman occupation is equivocal, and shows that the vegetation was variable [49,50]. One interpretation would suggest that the area was not clothed in dense ancient forest and wildwood: instead, it was probably quite open countryside with woodland, arable and grazing interspersed. This is relevant if it means that obtaining the timber and smallwood for the building of the large number of forts along the frontier involved long transport distances for the material, probably in carts.

Harvesting and working timber for the building of the early forts required a large and constant supply of hand tools along with their handles or hafts. There is good archaeological evidence that iron scrap was collected and reworked (see e.g. the Corbridge hoard above), and doubtless the fabricae would have provided new handles as well. The question as yet unanswered is where the new handles came from. Given the organisational zeal of the Roman Army, it would be surprising if local fort commanders relied on some distant depot to supply a product like a tool handle that could equally be made in the fort’s workshops, from material from the Army’s woodland or some other local source. There was a long tradition of coppicing within Europe, and it would not be far-fetched to suggest that the Army managed its own woodlands.

Building forts out of timber was expedient during the invasion phase, and was a tactic later employed by the Norman king William 1st following the AD 1066 invasion of England. More permanent structures would be needed thereafter, and away from the clay deposits of the south, the only alternative materials available were turf and stone. Winning and working these required equally sophisticated tools to those used for timber, and sufficient examples have survived on military sites to indicate the techniques used by the Army when creating permanent garrisons or defences.

Nowhere better illustrates this work than along the Hadrianic frontier across the narrowest part of northern England, between Carlisle and Newcastle. This was a frontier with depth, made up of a number of components, some linear and others intermittent along its length. The relationships between ditch, wall, forts, Vallum and road show up well in the aerial view looking east from above Housesteads Fort (Figure 7). It was probably constructed in 10-15 years [51].

In essence, the frontier controlled movement from Pax Romana in the south into the lands of the barbarians to the north, and vice-versa: it was not a defensive line like the trenches in France in WW1. Journeying from north to south a traveller would first have to negotiate a linear ‘V’-shaped ditch 8 m wide, nearly 3 m deep with all its crossings opposite gates in the wall itself. The ditch ran for some 96 km, and required the digging of over 1 million cu m of soil and rock [52]. Behind the ditch, and running the full length of the frontier was the curtain wall itself. Constructed of squared rubble, the outer faces of the shaped stones were more or less roughly squared with wide joints between them. These facing stones, 25 x 30 x 25 cm, weighed about 29 kg each [52] and 20 were needed for each square metre of wall. The wall itself varied in thickness, but averaged around 3 m and a height of 5 m. It is estimated that 24 million facing stones were required for the wall and the forts along its length. The stones were won from quarries opened as close to the wall as possible, and were worked using techniques and tools recognisable today such as bursting, splitting and dressing hammers and wedges to break the rock, and scrappling hammers, mallets, and chisels to square them. The shaped stones and the in-fill rubble probably weighed around 4 million tonnes and needed to be transported to the wall line: an operation requiring many thousands of vehicles of one kind or another [53]. The rubble core was set in clay or in lime mortar, the latter made from limestone quarried, crushed and burnt in kilns near the wall. Scaffolding, probably of alder (Alnus) and Ash, gave access to the walls for building at height. It is estimated that 150,000 linear metres (1,500 cu m) of scaffold poles would have been required, and the sourcing of such large quantities of timber of adequate quality in the area of the frontier would have presented significant problems, given that fuel for the lime kilns would need to be found at the same time. The wall, and the forts, milecastles and turrets along its length, were set upon sound foundations and the areas to accommodate them levelled. The mass of earth to be dug and shifted has not been estimated. But the primary tool for the job was the dolabra, the standard, multi-purpose pick-axe/mattock digging tool carried by each soldier as routine. Many hundreds of thousands of these beautifully designed, ergonomic tools would have been needed. Fine examples exist (Figures 9,12), and they show the same puzzling characteristic as the axe head, having a very small eye for the haft compared to the modern pick-axe handle. These tools were used for levelling, for felling trees and probably also for cutting turfs. In extremis they were very effective close-quarter weapons.

Figure 12: A scene from Trajan’s Column (Rome) celebrating the victory of Rome over the Dacians in AD 105. A legionnaire is felling trees with a dolabra, to clear forest and deny it’s sanctuary to enemy forces, for the building of a fortress, or for fuel etc. Trajan’s Column, Rome. 2nd Century AD.

Set some distance behind the wall, and creating a further impediment to accessing the wall itself and its buildings, a complex linear feature was constructed. Known as the Vallum, it demarcated the southern boundary of the military zone that was the frontier. It consisted of a ditch some 3 m deep and 6 m wide, the upcast spread as 1.5 m high mounds along both sides to form an obstacle over 40 m wide to all traffic, only crossed at 10km intervals. Over its entire length of 112km, the volume of earth and rock excavated and spread was around 1.5 million cubic metres.

At a later date, running roughly parallel to the Vallum and south of it, a road was constructed to link all the parts of the frontier together, and it serves to illustrate in general the efforts made by the Romans to create a network of all-weather routes linking the occupied areas of Britain. Roads varied in width, but most contained the same elements, namely a well-tamped foundation of coarse rubble, boulders or, in wet areas, log corduroy set in a shallow ditch the width of the metalled surface. This ran down the centre of an area cleared of obstructions such as trees, rocks and stumps, along which the roadside drains were cut. Depending on the nature of the subsoil, material from the drains was used to form the running surface or agger which was well compacted and cambered to provide water run-off into the drains.

Using 18th century data on the building of military roads in Scotland, Bishop [33] estimated a rate of construction of about 2 man-years per km of road. As with the construction of the ditch and Vallum on Hadrian’s Wall, this work depended on the use of hand-held tools, and on waggons or carts to transport the building materials as required. By the end of the Roman occupation, it is estimated that some 12,000 km of roads had been built in Britain.

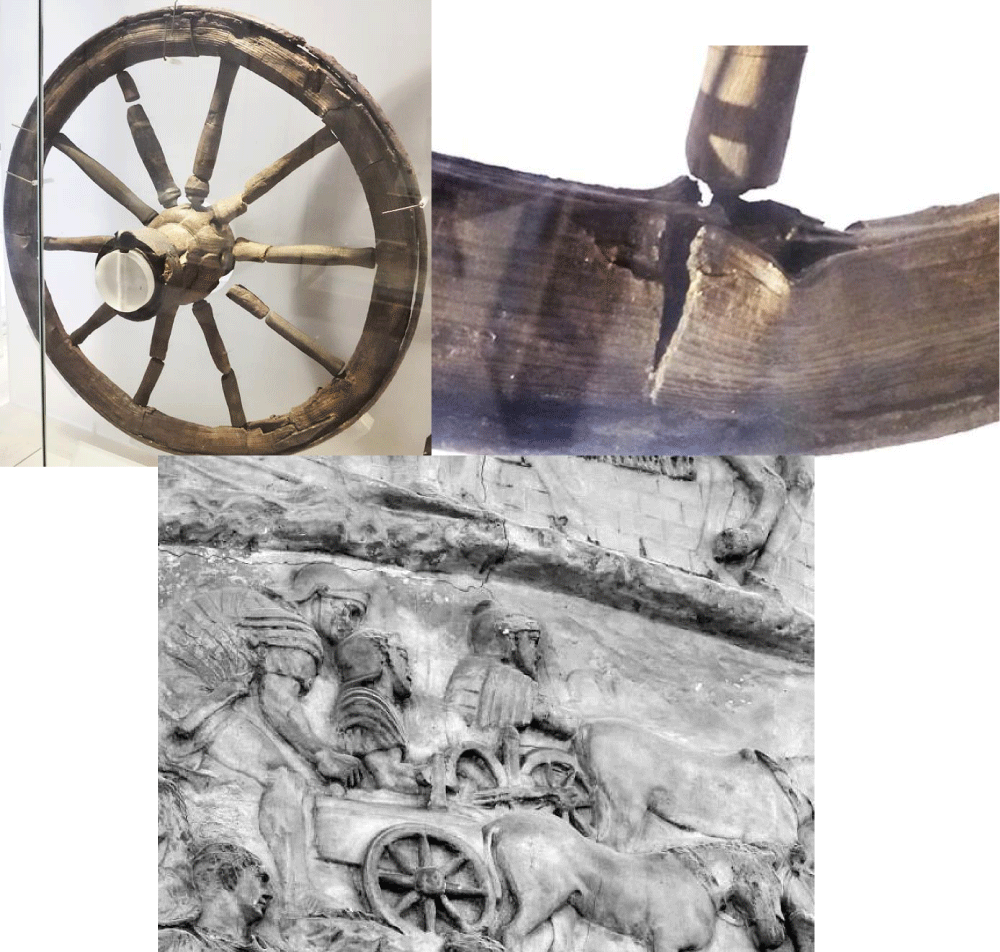

In each of the cases described above, where large masses of the building materials timber, wood, rock, limestone, sand and gravel had to be moved, it seems likely that wooden carts or waggons would have been employed. Three types of cart and their maximum loads were defined in the 4th century [52]: Angaria (490 kg), Raeda (328 kg) and Carus (164 kg), but there are no data on the waggons used by the Roman military in Britain. The use of carts for the transport of a wide variety of goods and equipment is well documented on Trajan’s Column (Figure 13), and a pair of wheels remarkably well preserved (Figure 13) was excavated at Trimontium [37]. These were iron-shod, roughly 1 m in diameter, with 10 spokes of willow fitted to the turned elm hub with square mortises. The spokes were fitted by means of round mortises into the felloe. Usually made from a number of curved lengths of wood, the felloe of this wheel is of a single 3 m length of Ash, steam-bent into a circle with the ends joined by an iron plate. This is a well-attested technique of wheel making, reaching back into the Iron Age [54] in Europe and, using Ash, to the 5th Century BC in Scotland [55]. While the techniques associated with the making of spoked wheels with several lengths of felloe “represents one of the masterpieces of prehistoric woodworking, combining extreme lightness with strength and durability, blending the different properties of different woods …to achieve the best possible combination…” [40], bending a single 3 m length of Ash into a perfect circle and then fixing it accurately to the hub by means of mortised spokes requires a technique that few today can aspire to. In the Trimontium wheels, the Ash was sufficiently well preserved to permit some observations to be made on it. The felloe was split from a clear length of Ash, with about 19 annual rings set within its 10 cm width (i.e. an annual growth rate of around 5 mm). Because the wheel is encased in a glass cabinet, it was not possible to make observations on the profile of the felloe, but from the photograph it looks roughly rectangular. The distortion of the annual rings around some branch initials would suggest that the bend was radial, with the sapwood on the outer edge, next to the iron tyre. The felloe shows clear evidence of failure, where one of the spokes has sprung out of its mortise (Figure 13). This distortion shows signs both of compressive and tensile failure. Such failure might occur if the wheel was over-loaded and hit an obstacle. Once broken, the wheel along with another was discarded.

Figure 13: Roman Army single-felloe cart wheel excavated from a pit in the fort at Trimontium. The felloe is a single 3.1m length of Ash, steam-bent into a circle of approx. diameter 1.0m, encircled by an iron rim. The felloe came from a relatively slow-growing tree, and at some stage it failed at the junction with one of the spokes (below). Both the hub and the spokes were nicely turned on a lathe, the hub of elm, and the spokes of willow. Trimontium, 150 AD The wheel is in the National Museum of Scotland, Edinburgh and the photographs (taken through glass) are reproduced with their kind permission. The use of carts by the Roman Army is well attested on Trajan’s Column, in Rome (see Fig 3). In this case, carts are pictured carrying carrobalista artillery. Trajan’s Column, Rome. 2nd Century AD.

This technique of making single-felloe wheels lasted into the middle Ages in Britain, when the tradition was lost [56]. However, it had lasted for nearly 1000 years, and presupposes that the mysteries of the technique were handed down from father to son and that an adequate supply of high-quality fast-grown Ash suitable for this severe bending was readily available locally. Given that such material would be available from coppiced woodlands, but only if the coppice was regularly cut and managed [57] raises the question of its disappearance from the countryside. As an example of the decline in coppicing as a means of managing woodland, it is instructive to see that in 1952, of a total of 47,500 ha of hazel coppice in England, 42,500 ha (89%) was classed as unworked. A system that had been successfully used for hundreds if not thousands of years up until a century ago has virtually disappeared, along with most of the skills and knowledge that underpinned it.

We have no evidence that the Roman Army created and managed any woodland in Britain to provide it with the timber resource that, in its expansion phase, it so clearly needed. But the Army’s attention to detail, its ability to plan ahead and its pragmatic organisation would make it seem unlikely that it did nothing to safeguard an essential commodity as important as timber. That a system of coppice woodland management developed in England after the Norman invasion that has, in tiny parts, survived to today probably has nothing to do with the Roman Army.

For most of the 1600 years that have passed since the Roman occupation of Britain came to an end, the population of these islands has been dependent on Ash to provide it with the tools needed to work the land. By the time of the Doomsday census of 1086, around 90% of the population (of 2 million) did not live in towns but were involved in agriculture. By 1850, only half the population depended on agriculture but, since it had risen to 27 million, this left perhaps five million and their dependants working in farms and forests with hand-held tools whose handles and hafts, if made from Ash, were strong, flexible, resilient, free from splinters and locally available. Ash met those requirements better than any other species commonly available in Britain.

Ash today

The industrialisation of farming and the reliance on coal, oil and electricity instead of wood for fuel has reduced the demand for Ash in the last century or so. The species is now valued more for its conservation attributes than for the properties of its timber.

However, there remains a small market for sports and domestic goods which has been recently described by Rackham [12] and Penn [13]. Notably, good quality Ash is used today in bespoke Morgan Cars, hand-made in Malvern, using Ash for the frame on which the aluminium bodies are fitted. This work (Figure 14) requires standard components accurately machined and bent to accommodate the tight tolerances needed in a light sports vehicle capable of 155 mph (255 kph). The finest of bent- wood furniture uses Ash: Dan Hussey’s complex furniture (Figure 3) is constructed from planks split from coppiced Ash from Bradfield Woods (see above). Both these industries continue the tradition of matching the product to the appropriate material.

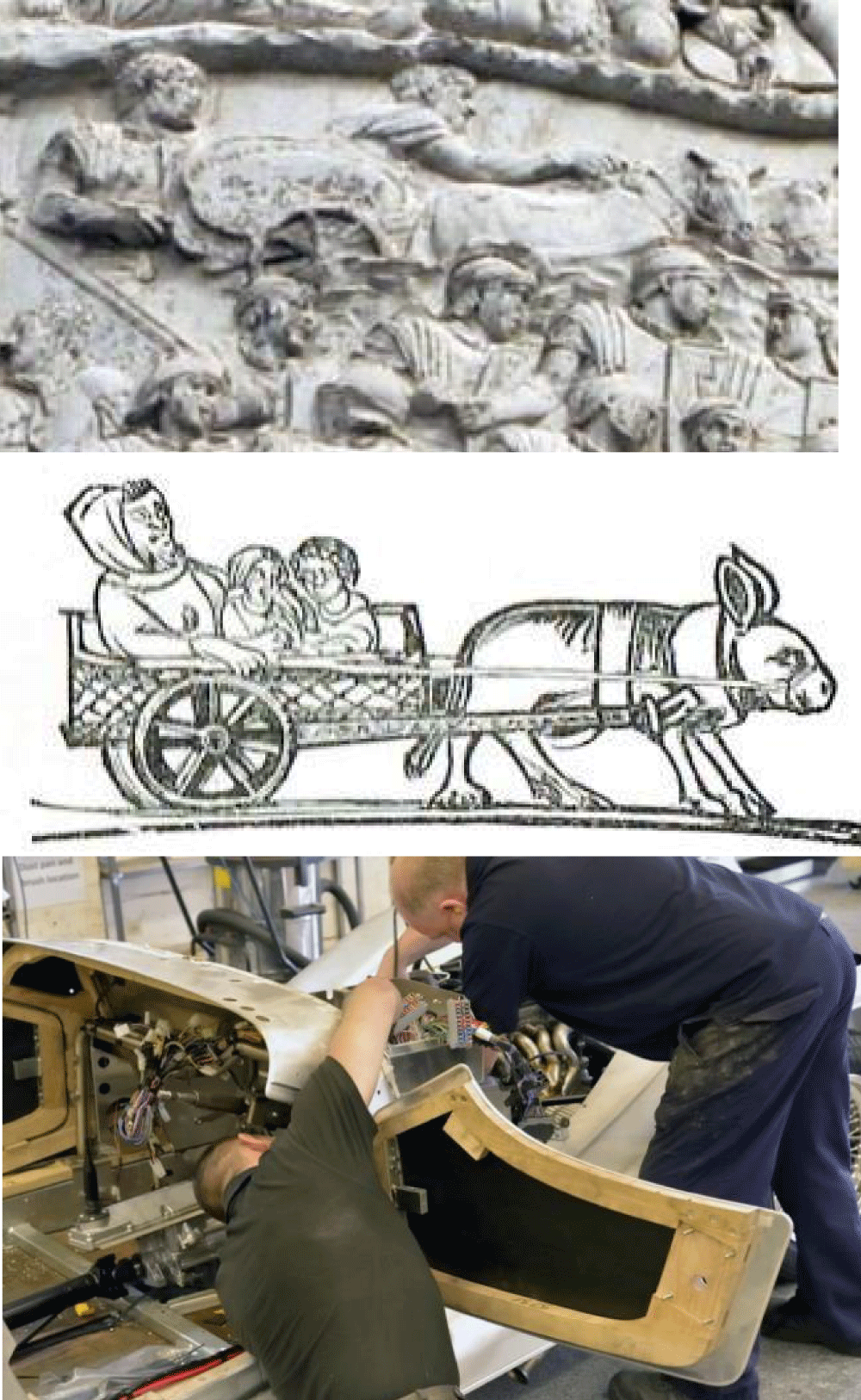

Figure 14: Each of these images is separated by about 1000 years, yet each involved Ash in some form of transport. First, the Emperor Trajan’s troops use a mule-drawn cart to move what looks like a tent in the campaign against the Dacians, 2nd Century AD. From Medieval England a family is transported in a dog cart. From modern England, a Morgan sports car is created using Ash for the framework at the Malvern factory, 2013.

The utility of Ash is summed up in a recent poem [58] which celebrates a crucial agricultural practice, commonplace up to the 1950’s, of stacking harvested wheat sheaves (bundles) in a barn for later threshing:

Bright prongs pierced and unpicked, ash handles bent, they launched the bundles we embraced, laid in a level course, crammed into corners, trod tight. Crispness, countless swathes of kizzened grass pricked our skin, there was wildflower scent in our nostrils. When our heads bumped the slates We came down the ladder in triumph.

What relevance does past use have on the survival of the species now?

In any project to preserve the gene pool of our native Ash against the possible extinction of the species from the combined onslaught of Ash Dieback (Hymenoscyphus fraxineus Queloz, et al.) and of the Emerald Ash Borer (Agrilus planipennis Fairmarie), it is perhaps necessary to consider to what extent the past use of Ash may have affected the genetics of the present population.

There seems to be wide consensus that Ash has been managed by coppicing in the past, to provide easily-harvested wood of appropriate size and strength to meet the local demands for tool handles, weapons, building materials and fuel. The extent to which coppicing involves selection of desirable traits is perhaps not clear. But given the relationship between growth rates, strength and flexibility described above, it would be surprising if the Ash population in Britain has not been subject to structural “improvement” over the past few thousands of years, making it better suited to the needs of a pre-industrial agrarian society which would have valued rapid growth and relatively short rotations. In addition, it can be argued that the immense age of some of the coppice stools will have tended to influence genetic variation among the existing population. And because Ash is dioecious, it is also possible that selection may have been biased towards either predominantly male or female trees if there are differences in growth patterns between the sexes. Whatever the truth, it is worth bearing in mind that for several thousands of years, Ash had a special place in our history and it will be a tragedy if it has come to an end.

Of all the native hardwood species available to man in Britain over 12,500 years since the retreat of the last Ice age, Ash has been the most utilitarian, providing a consistent and reliable resource that has been central to man’s development from a hunter-gatherer to a sophisticated space-walker. However, few in Britain today realise how central it has been to the creation of infrastructure now taken for granted. This is highlighted in this paper by reference to the remarkable (and novel) building by the Roman army of occupation over 300 years ago, only made possible by using the best timber for tool handles: namely Ash. Such items do not survive for long and only turn up within archaeological excavations as undifferentiated stains in the ground. The forthcoming extinction of Ash by an exotic disease imported from another continent is, unfortunately, a symptom of the disdain shown by modern man for his environment and the history of its development.

Keith Barber, Mike Bishop, Peter Fordham, Peter Gasson, Bill Hanson, Fraser Hunter, Robert Hurford, Dan Hussey, Chris Stringer, Dirk Sporleder and Alison Sheridon have patiently submitted to my interrogation and given me copies of their papers. Angela Pitt and David Lonsdale kindly reviewed the text. Margaret Wilson, National Museums Scotland, generously gave permission for the use of my photography of the Museum’s exhibits, and the Suffolk Wildlife Trust made their map of Bradfield woods available. David Lonsdale’s expert opinion on the nature of the failure of the wooden wheel was particularly appreciated.

Except where credited, all the photographs are the author’s, as are all the errors.

Introductory

This paper was originally published as the opening chapter to an EU Cost Research Programme Report into Ash Dieback (ISBN 978-91-576-8697-8), and it is reproduced here with the kind permission of the Copyright holders, the Swedish University of Agricultural Science, to whom I offer my thanks.

Ash (Fraxinus excelsior L.) is subject to the threat of extinction from an alien disease imported into Europe from another Continent, namely Asia. Related species in N America are also under threat from insects from the same continent. Until proper controls are instigated to control the inter-continental movement of plants, such risks are unfortunately inevitable. It is to publicize the risk that this paper is being re-published in another continent, namely N America.

- Maigrot Y. Neolithic polished stone axes and hafting systems: technical use and social function at the Neolithic lakeside settlements of Chalain and Clairvaux. In: Davis and Edmonds (eds.) Stone Axe Studies III. Oxbow Books, Oxford. 2011; 441.

- Mytting L. Norwegian Wood. Chopping, Stacking and Drying Wood the Norwegian Way. MacLehouse Press, London. 2015; 192.

- Green HS. Late Bronze Age wooden hafts from Llyn Fawr and Penwyllt and a review of the evidence for the selection of wood for tool and weapon handles in Neolithic and Bronze Age Britain and Ireland. Bull. Board of Celtic Studies. 1978; 28: 136-141.

- Harding A, Young R. Reconstruction of the hafting methods and function of stone implements. In McK Clough and Cummins (eds.) CBA Research Report No 23: Stone Axe Studies. Council for British Archaeology, Lond. 1979; 137.

- Sheridan A. Scottish stone axeheads; some new work and recent discoveries. In Sharples and Sheridan (eds.) Vessels for the Ancestors: Neolithic of Britain and Ireland. EUP, Edinburgh. 1992; 416.

- Cooney G, Mandal S. The Irish Stone Axe Project, Monograph 1. Wordwell Ltd, Bray, Ireland. 1998; 220.

- Dinnis R, Stringer C. Britain: one million years of the human story. Natural History Museum, London. 2014; 152.

- Thieme H. Lower Paleolithic hunting spears from Germany. Nature. 1997; 385: 807-810.

- Brazier JD. The Timbers of Farm Woodland Trees. Bulletin, Forestry Commission No 91, HMSO, Lond. 1990; 8.

- Desch HE, Dinwoodie JM. Timber: structure, properties, conversion and use. Palgrave Macmillan. 1996; 306.

- Cook J, Gordon JE. A mechanism for the control of crack propagation in all brittle systems. Proc Royal Soc A. 1964; 282: 508.

- Rackham O. The Ash Tree. Little Toller Books, Dorset. 2014; 178.

- Penn R. The Man who Made Things out of Trees. Particular Books, 2015; 234.

- Evans J. Silviculture of Broadleaved Woodland. Forestry Commission Bulletin 62. H.M.S.O. Lond. 1984; 232.

- Hiley WE. A Forestry Venture. Faber and Faber, Lond. 1964; 240.

- Rackham O. Neolithic woodland management in the Somerset levels: Gavin’s, Walton Heath and Rowland’s tracks. In Coles et al (eds.) Somerset Levels Project No. 3. 1977; 65–72.

- Milner N, Taylor B, Conneller C, Schadia-Hall T. Star Carr. Life in Britain after the Ice Age. Council for British Archaeology, York. 2013; 112.

- Catling C. Bouldnor Cliff: a glimpse into the Mesolithic. Current Archaeology. 2012; 262: 31-37.

- Coles J. An experiment with stone axes. Pages 106-107 in: McK Clough and Cummins (eds.) CBA Research Report No 23: Stone Axe Studies. Council for British Archaeology, Lond. 1979; 137.

- Jacomet S, Leuzinger U, Schibler J. The Neolithic lakeside settlement of Arbon, Bleiche 3. Environment and economy. Reprint synthesis from archeology in Thurgau 12. Frauenfeld. 2004.

- Dumayne-Peaty L, Barber K. Archaeological and environmental evidence for Roman impact on vegetation near Carlisle, Cumbria: a comment on McCarthy. The Holocene. 1997; 7(2): 243-246.

- McCarthy MR. Woodland and Roman Forts. Britannia. 1986; 17: 339-343.

- Rackham O. The history of the countryside. Dent, London. 1986; 445.

- Coles B. Wood species for wooden Figures: a glimpse of a pattern. In: Gibson and Simpson (eds.) Prehistoric Ritual and Religion: Essays in honour of Aubry Burl. Sutton Publishing. 1998.

- Coles JM, Orme BJ. Prehistory of the Somerset Levels. Somerset Levels Project 1980. 1982; 64.

- Thomas PA. Biological Flora of the British Isles: Fraxinus excelsior. Journal of Ecology in press. 2016; 2745.12566.

- Brondsted J. The Vikings. (trans. E. Bannister-Good.) Penguin Books, Lond. 1960; 320.

- Frazer JG. The Golden Bough. Macmillan, Lond. 1949; 756.

- Margary I. Roman Roads in Britain. John Baker, Lond. 1967; 546.

- Webster G. The Roman Imperial Army of the first and second centuries AD. Adam and Charles Black, Lond. 1969; 330.

- Wacher J. The towns of Roman Britain. Batsford. 1974; 460.

- Peddie J. Conquest: the Roman invasion of Britain. Sutton Publishing, Glos. 1987; 214.

- Bishop MC. The secret history of the Roman roads of Britain. Pen and Sword Military, Barnsley. 2014; 210.

- Cunliffe B. Iron Age Britain. Batsford, Lond. 1995; 128.

- Millett M. How Roman occupation redrew an iron-age landscape. Current Archaeology. 2016; 314: 26- 31.

- Breeze DJ. The Northern frontier of Roman Britain. Batsford, Lond. 1982; 188.

- Curle J. A Roman Frontier Post and its People. Maclehose, Glasgow. Vols I and II. 1911.

- Bishop MC, Coulston JCN. Roman Military Equipment, 2nd Edition. Oxbow, Oxford. 2013; 322.

- Webster G. The Roman Army: An Illustrated Study. Grosvenor Museum, Chester. 1956; 52.

- Coles JM, Heal SVE, Orme BJ. The use and character of wood in prehistoric Britain and Ireland. Proc Prehistoric Society. 1978; 44: 1-45.

- Travis H, Travis J. Roman Shields. Amberley Publishing, Stroud. 192. Vegetius PFl. Epitoma rei militaris. II, 11. 2014; 192.

- Bishop MC. The Gladius. Pers Comm. 2016.

- Pitassi M. The Roman Navy. Seaforth. 2012; 184.

- Nash-Williams VE. The Roman frontier in Wales. University of Wales Press, Cardiff. 1969; 206.

- Hanson WS. The organisation of Roman military timber supply. Britannia. 1978; 9: 293-305.

- Shirley E. Building a Roman legionary fortress. Tempus. 2001; 160.

- Richmond IA. Roman Timber Building. In Jope (ed.) Studies in Building History. Odhams, Lond. 1961; 287.

- Hanson WS. Elginhaugh: a Flavian fort and its annex. Britannia Monograph Series No. 23, S.P.R.S., London. 2007; 686.

- Dumayne-Peaty L, Barber K. Late Holocene vegetational history, human impact and pollen representivity variations in northern Cumbria, England. Journal of Quarternary Science. 1998; 13(2): 147-164.

- Tipping R. Medieval woodland history from the Scottish Southern Uplands. In Smout (ed.) Scottish Woodland History. Edinburgh. 1997; 215.

- Breeze DJ, Dobson B. Hadrian’s Wall. Allen Lane. 1976; 324.

- Hill P. The construction of Hadrian’s Wall. Tempus. 2006; 160.

- Moffat A. The Wall: Rome’s greatest frontier. Berlinn, Edinburgh. 2009; 270.

- Crouwel JH. Chariots and other wheeled vehicles in Italy before the Roman Empire. Oxbow, Oxford. 2012; 234.

- Carter S, Hunter F, Smith A. A 5th Century BC Iron Age Chariot Burial from Newbridge, Edinburgh. Proc. Prehistoric Society. 2010; 76: 31-74.

- Jenkins JG. Traditional Country Craftsmen. Routledge & Kegan Paul, Lond. 1966; 236.

- Anon Utilisation of Hazel Coppice. Bulletin No 27, Forestry Commission, HMSO, Lond. 1956; 34.

- Rawling T. The Barn. In Slater and Rawling (eds.) How Hall: Poems and memories, a passion for Ennerdale. Lamplugh and District Heritage Society, 2009; 90.

- Stevens WC, Turner N. Woodbending Handbook. HMSO. 1970; 109.