More Information

Submitted: May 31, 2023 | Approved: June 08, 2023 | Published: June 09, 2023

How to cite this article: Olowosebioba AA, Folorunsho AD, Akindele BA, Akingbade FS, Andrew IO, et al. Design and construction of solar-powered smart garbage disposal unit. Ann Civil Environ Eng. 2023; 7: 024-029.

DOI: 10.29328/journal.acee.1001052

Copyright License: © 2023 Olowosebioba AA, et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Keywords: Arduino nano; Ultrasonic sensor; Solar panel; Easy EDA; Sanitation

Design and construction of solar-powered smart garbage disposal unit

Olowosebioba AA1*, Folorunsho AD1, Akindele BA1, Akingbade FS1, Andrew IO2, Olaniyi GA3 and Dada OJ1

1Physics with Electronics Unit, Science Laboratory Technology, Ogun State Institute of Technology, Igbesa, Nigeria

2Physics Department, Lagos State University, Ojo, Nigeria

3Crescent University, Abeokuta, Nigeria

*Address for Correspondence: Olowosebioba AA, Physics with Electronics Unit, Science Laboratory Technology, Ogun State Institute of Technology, Igbesa, Nigeria, Email: [email protected]

Cities with developing economies experience exhausted waste collection services, and inadequately managed and uncontrolled dumpsites; which is an ongoing challenge and many struggles due to weak institutions and rapid urbanization. The purpose of the research is to design and construct a smart garbage disposal system using a two-way power supply unit (that is, the electrical power supply unit and solar power supply unit) based on Arduino Nano that utilizes ATMEGA 328p microcontroller. Two pairs of ultrasonic sensors, the pair that faced upward detects the presence of garbage disposal agent at a close distance of (5 - 50) cm and then opens the lid while the other pair faced the inside of the container senses when the container is filled up and then closes the container until it is emptied are used.

Waste management is all the activities and actions required to manage waste from its inception to final disposal [1]. A garbage disposal unit is a container that collects garbage or stores items that are recyclable or non-recyclable, decomposable, or indecomposable. It is usually used in homes, offices, and others, but in case it is fully loaded unaware the garbage is spilled out into the environment and causes nuisance all around. The containers which collect debris and store them automatically without allowing them to spill out into the environment are known as smart garbage disposal units.

Waste management thwarts harm to human health and the surroundings which reduces the volume and hazardous character of residential and industrial waste. Improving proper waste management also reduces pollution, recycles useful materials, and creates more green energy [2].

The methods by which wastes are managed include collection, transportation, treatment, and disposal of waste together with monitoring and regulations. Waste collection methods vary widely among different regions and countries. Curbside collection, in which waste is collected at regular intervals by specialized trucks, is the most common method of waste disposal in some countries. Waste collected is then transported to an appropriate disposal area [3].

Nowadays, cities with developing economies experience exhausted waste collection services, and inadequately managed and uncontrolled dumpsites; and the problems are worsening [4]. One such problem is the issue of domestic solid waste disposal that causes pollution [5,6]. The build-up of waste then caused a rapid deterioration in levels of sanitation as well as the overall quality of metropolitan life [7]. Waste collection method in such countries is an ongoing challenge and many struggles due to weak institutions and rapid urbanization.

Therefore, a smart garbage disposal unit uses Arduino Nano and ultrasonic sensors to detect the quantity of waste in a bin and update them on the status of the bin which senses the item to be thrown in the dustbin. Even though it’s touch-free, the dustbin’s lid will automatically open when someone approaches it, eliminating the need for manually opening the grimy cover since it opens and close the lid with the help of the motor. It brings a new and smart way of cleanliness. It is a decent gadget to make the home clean, due to practically, all offspring consistently making it grimy and spread litter to a great extent by electronics, rappers, and various other things. Since the smart dustbin is additionally intriguing and children make fun of it, it will help to maintain cleanliness in the home. It can be applied to various types of waste. Dustbin will open its lid when someone/object is near at a certain range and wait for a given time period then it closes automatically. Here the lid will close when unused and open only when required.

Environmental problems are raised by modern cities for waste collection and disposal [8]. Hong, et al. [1] reported that the breeding of insects and mosquitoes can create a nuisance around and promote an unclean environment which may even cause dreadful diseases. Early garbage removal trucks were simply open-bodied dump trucks pulled by a team of horses which became motorized in the early part of the 20th century and the first close-body trucks to eliminate odors with a dump lever mechanism were introduced in the 1920s in Britain [9].

The purpose of this work is to design and construct a device that will tackle and solve environmental challenges automatically by making use of solar power and a battery source module as an alternative power source in order to prevent power challenge in the day and enhances its functionality at night. Therefore, smart waste solar power supply systems become essential for cities that aim at reducing cost and managing resources and time [10]. The attractiveness and smartness of the smart garbage disposal device create easy to use, hands-free, and stress-free method for waste collection and it is developed to prevent environmental disasters.

Materials

The major materials used for the software of the design of the solar-powered smart garbage disposal unit and the hardware of its construction while implementing the design are enlisted in Table 1.

| Table 1: Software / Hardware Used. | |

| Name of Software/Hardware | Uses of Hardware in the proposed system and specification |

| Arduino IDE | For Programming and Uploading the code to Arduino Nano Board, connected via USB cable to the computer. |

| Easy EDA | For the design of the circuit diagram and PCB |

| Arduino Nano | To control and operate the system. It is connected to all the components of the system. Specifications: 32KB Flash memory, 1KB EEPROM, 2KB SRAM, 16MHz Clock, 14 Digital I/O, 6 Analog Inputs, 6 PWM Output Pins, 12C Bus, Serial Bus (Tx, Rx). |

| Ultrasonic sensor | To sense the height of the garbage in the dustbin and compare it with the garbage bin depth. Supply voltage 5 v, Global Current Consumption 15 mA Ultrasonic Frequency 40k Hz, Maximal Range 400 cm, Minimal Range 3 cm, Resolution 1 cm, Trigger Pulse Width 10 µs, Outline Dimension 43x20x15 mm. |

| Solar Panel | PV solar panels generate direct current (DC) electricity. With DC electricity, electrons flow in one direction around a circuit. |

| Battery | 3.2v (2 batteries connected in series) |

| Servo motor | Used to open the lid of the dustbin |

Other required hardware materials used for the construction of solar-powered smart garbage disposal units are:

I. Printed Circuit Board (PCB)

II. Resistor

III. Jumper wires

IV. JST Connector

V. Cables

VI. Power control module

VII. Female header

VIII. A small dustbin with a hinged lid

IX. Miscellaneous (such as glue, screws, and others)

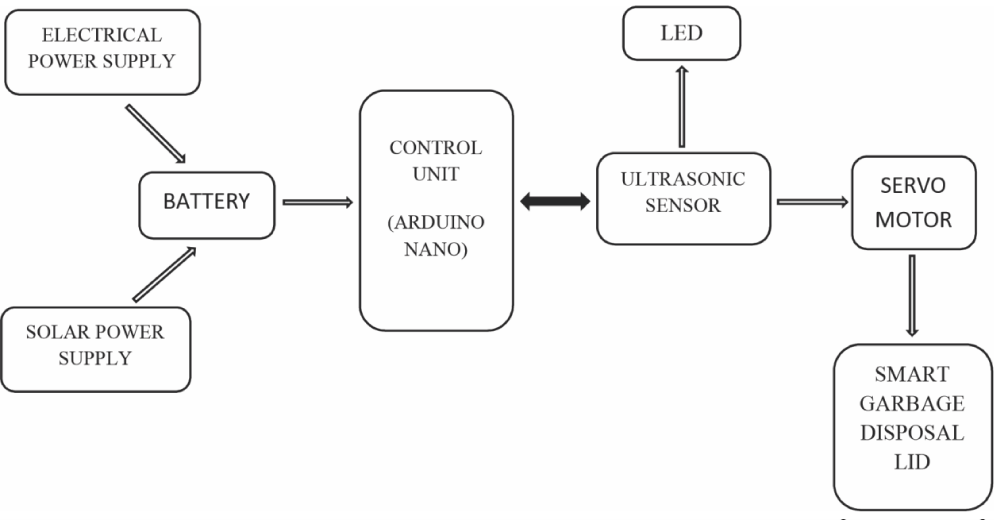

System block diagram (Figure 1)

Figure 1: Block Diagram of Smart Garbage Disposal Unit.

Figure 1 represents the block diagram of the smart garbage disposal unit.

Methods

The smart garbage disposal system used a two-way power supply unit. The electrical power supply unit from the mains supplied 220vAC to the system through the power supply module which rectified the voltage and supplied 5v to the system. Also, a solar power supply unit is attached to the device as an alternative power supply. The PSU then charges a lithium battery.

The control unit of the overall system centred on Arduino Nano which utilized ATMEGA 328p microcontroller. It executes programs in order to control other devices or modules used for the other units of the smart garbage disposal system. The microcontroller is supplied with a 5v controlled power supply. Arduino Nano is the main Module in the construction.

The ultrasonic sensor which is interfaced with Arduino Nano is in pairs of two. Each pair performs different functions; one faced upward and the other pair faced the inside of the trash can.

The pair that faced upward detects the presence of a garbage disposal agent at a close distance of (5 - 50) cm. Then, the indicator light turns ON and Arduino will activate the servo motor, and with the support of the extended arm, the lid opens within twenty seconds to allow the disposal agent to drop their garbage inside the dustbin. The other pair that faced inside of the trash can is to check the level of the garbage; whether it filled up or not. If it is filled up at a distance of 5 cm from the garbage, Arduino Nano activates the sensor and the lid remains closed until the garbage inside the bin is removed. The LCD interfaced with the Arduino displays that the garbage is full inside the trash can.

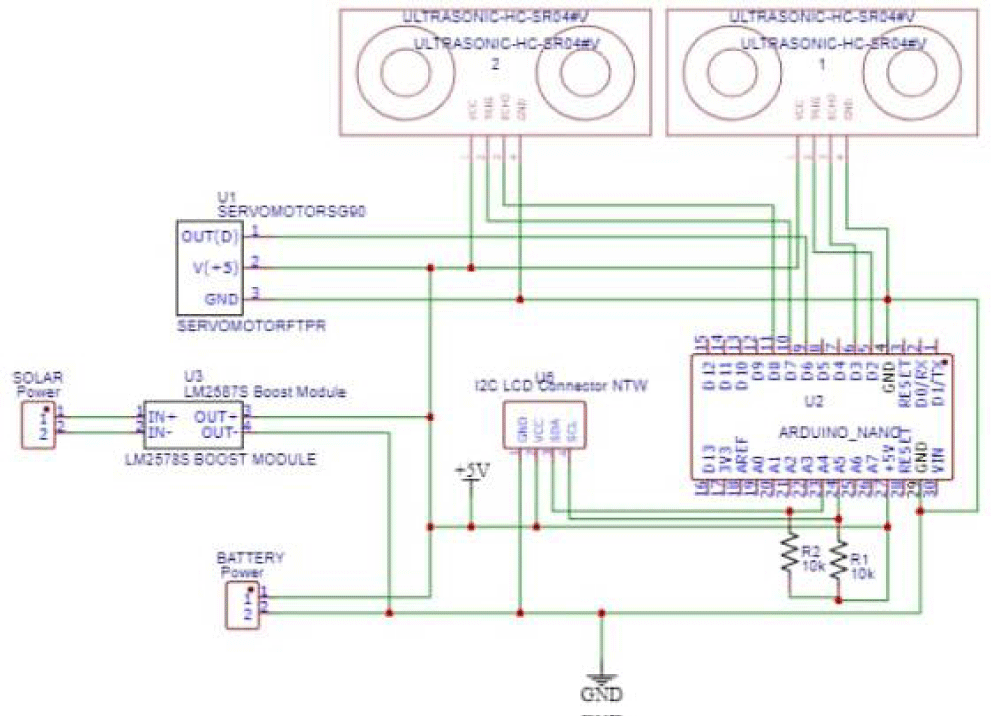

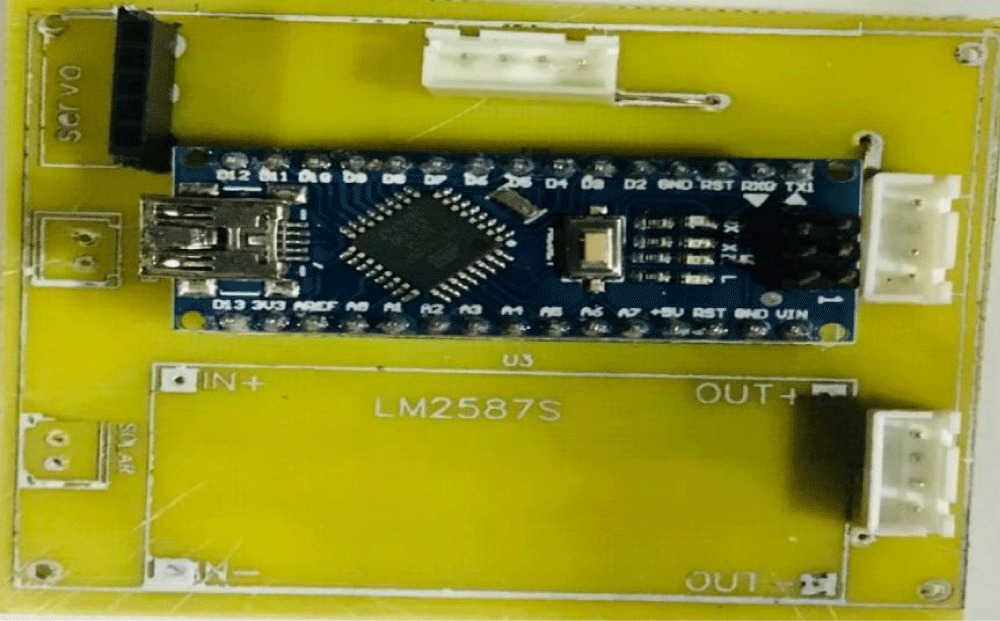

The circuit diagram of the smart garbage disposal system was designed using Easy EDA design software. It consists of components listed in subsection 3.2.2. The active programmable microprocessor used is Arduino Nano. The microprocessor was used in processing the programmes for controlling the activities of the LCD, ultrasonic sensors, and servo motor. After successfully simulating the design, the final circuit layout of the system is shown in Figure 2.

Figure 2: Circuit Layout of Smart Garbage Disposal System.

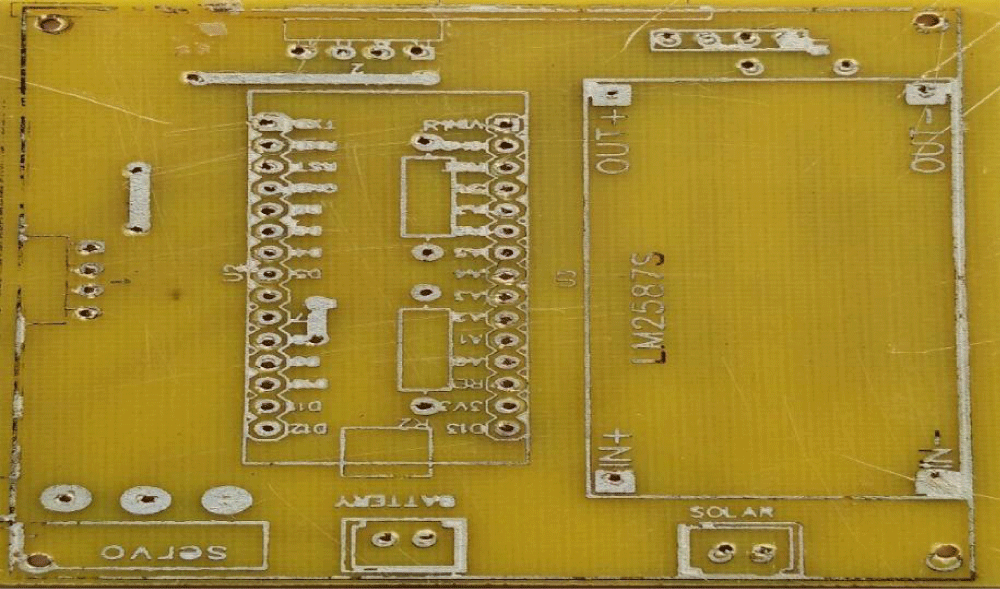

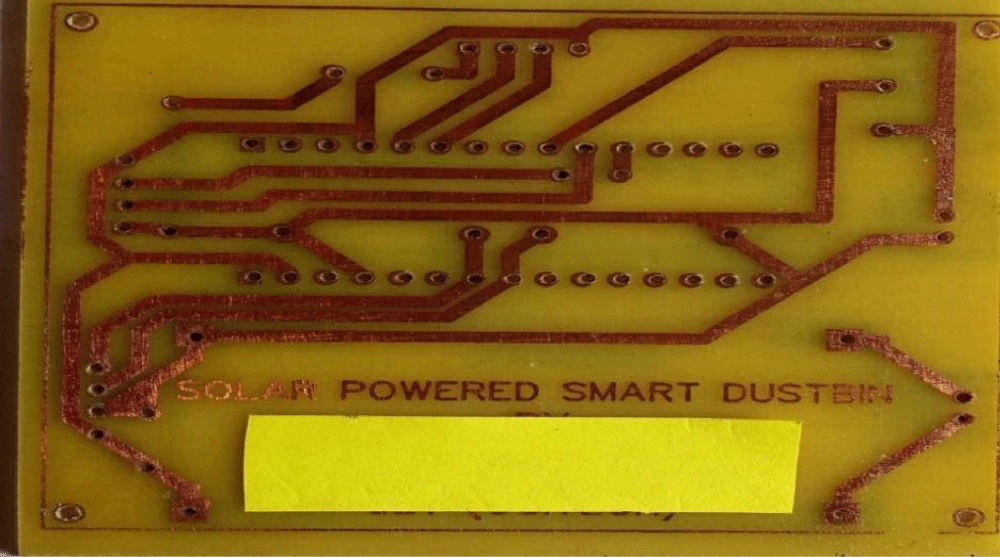

Printed circuit board (PCB) description

Every electronic device requires a rigid circuit to perform its specific task. The PCB pattern was created with the aid of Easy EDA (CADs) design software. The circuit designed for the system was converted to a PCB pattern layout where the position of each component is described. The pinpoint for the individual corresponding component is drilled after the etching of the PCB. Figures 3,4 show the front and back views of the final PCB construction.

Figure 3: Final front view of PCB.

Figure 4: Final back view of PCB.

Components assemblage

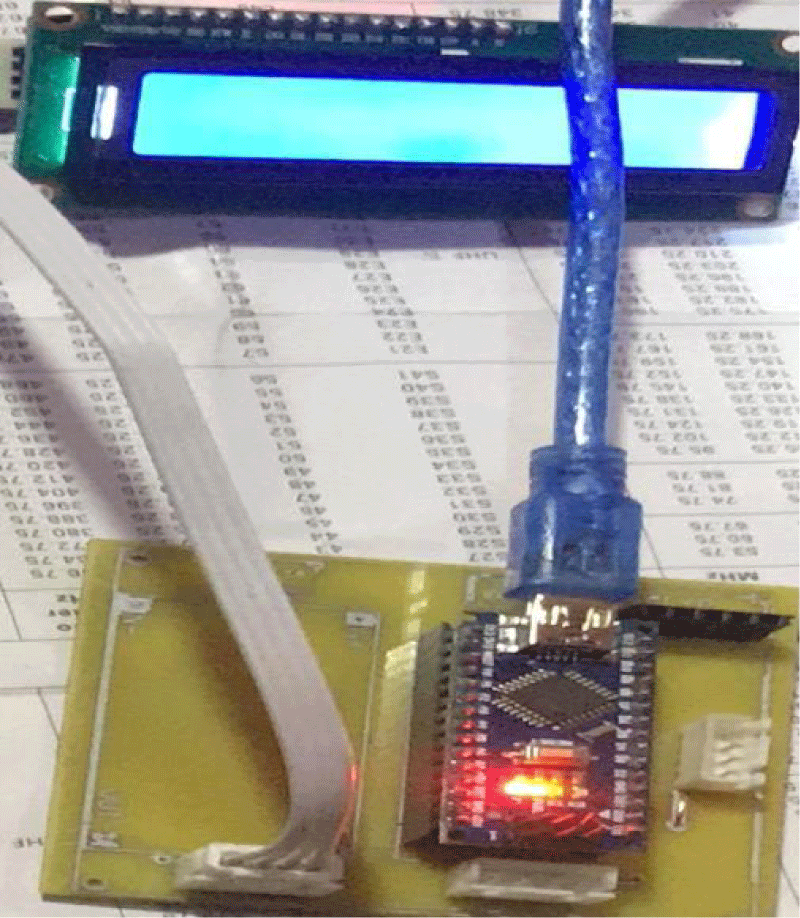

Jumper wires were fixed and soldered in order to bridge some disconnected lines and then components were fixed and soldered to the appropriate position as indicated on the PCB. Female headers (pin line) were fixed and soldered carefully to avoid joint connection and then, the Arduino Nano was fixed onto the side-by-side soldered female headers (Figure 5).

Figure 5: Mounting Components on PCB.

Having fixed the 10k resistor on the PCB, the J-S-T cable corresponding to the servo motor was connected and that which corresponds to the ultrasonic sensors, and Liquid Crystal Display (LCD) were also connected to their appropriate position on the PCB as shown in Figure 6.

Figure 6: J-S-T connected to LCD from PCB.

The servo motor was connected near the hinge of the lid. Holes corresponding to the ultrasonic sensor and the LCD size were created on the lid of the trash bin. Then, PCB and other output components were mounted on the garbage disposal trash bin with the help of glue and screws. The power supply outlet was screwed to one side of the trash and the solar panel was placed on the trash bin cover.

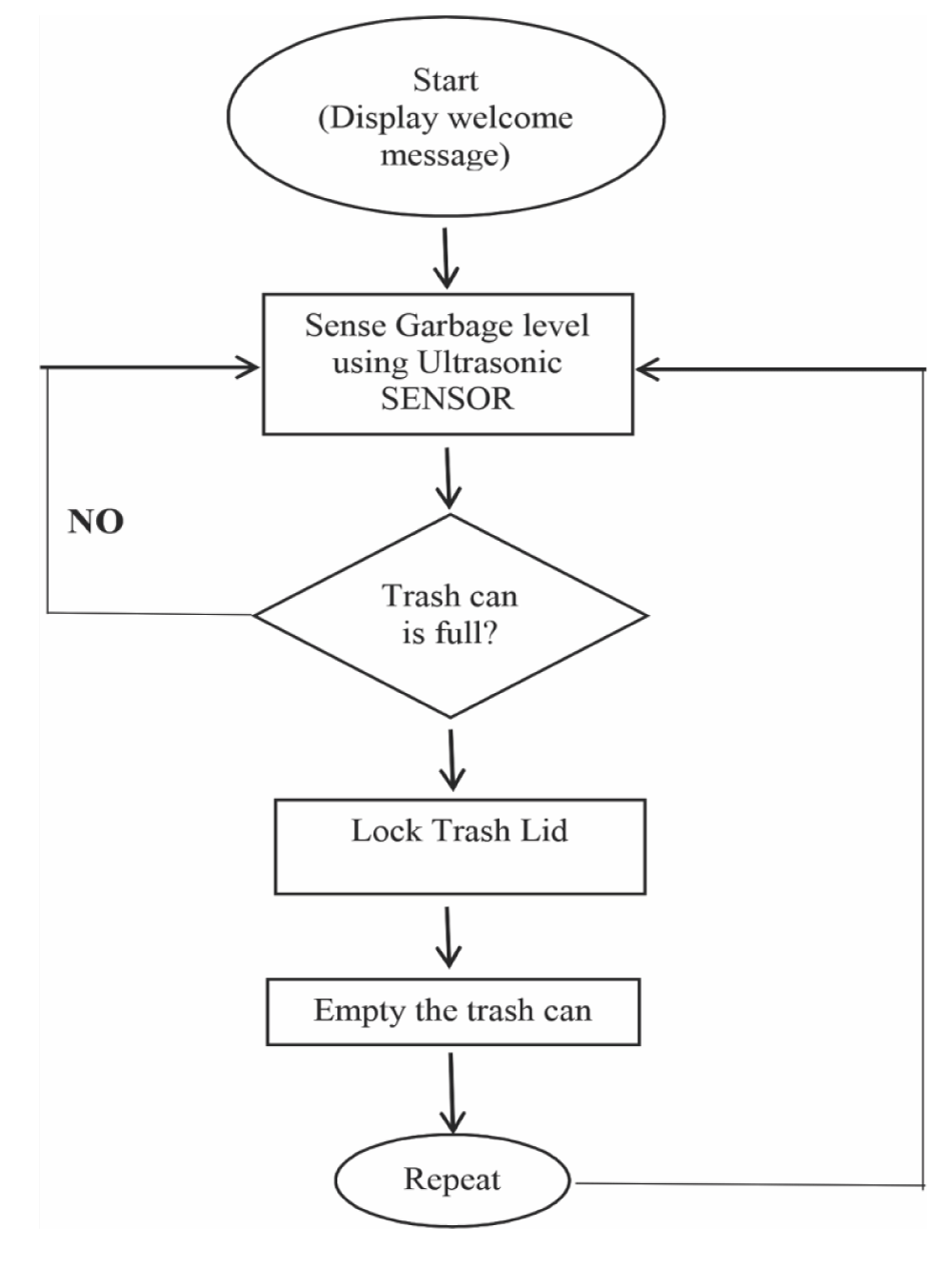

Simulation and algorithm

Figure 7 shows the flowchart of the smart garbage disposal system and the simulation command code using Arduino IDE software is displayed for each digital component used. The under-listed is the step-by-step algorithm of the smart garbage disposal system.

Figure 7: Flowchart.

I. Step 1: Start (Display welcome message).

II. Step 2: Check the value from the ultrasonic sensor.

III. Step 3: Update the status of the garbage disposal bin on the LCD Screen.

IV. Step 4: If the Sensor value > Threshold Value, the trash lid closed is detected.

V. Step 5: Else go to step 2.

VI. Step 6: Empty the dustbin and then go to step 2.

VII. Step 7: Repeat.

Result analysis

After verification and compilation of the programming language on the Arduino IDE, the complete design mounted on the PCB was connected to the Personal Computer. The programme was then uploaded to the Arduino Nano board (Figure 8) as it was fixed on the trash bin. The uploading takes some minutes and the Arduino IDE displays “done compiling”. This shows that it was uploaded successfully. After this, it was tested to observe its operation. The design worked according to Yujie, et al. [11] suggestion that the programming of the loop body needs to directly or indirectly call the functions of each module and make some logical judgments, and finally achieve the corresponding design requirements.

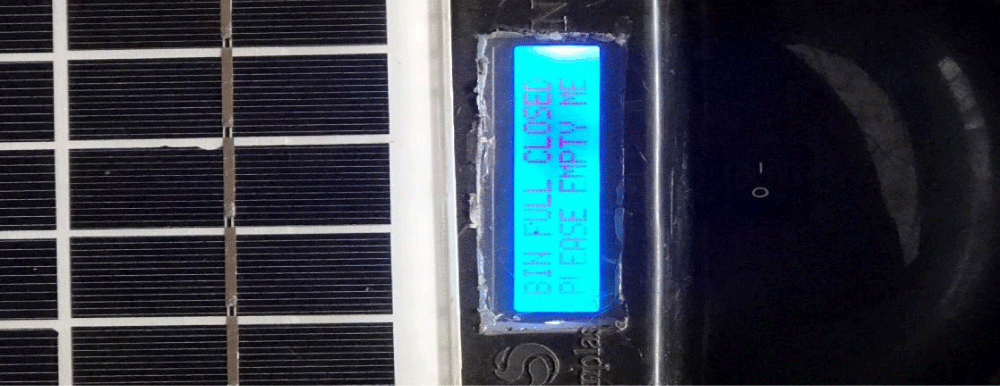

Figure 8: Liquid Crystal Display is Connected with Arduino Nano Board for Uploading.

Having provided the casing and finished the construction of the sections of this system, assembly into the casing followed. The sections were properly fixed and assembled.

Finally, the battery leads, solar panel, and ultrasonic sensor were carefully fixed outside the trash bin from the internal part of the casing through the holes made in the body of the casing. The regulated power module which was rectified to a 5vDC power supply was used.

Table 2 shows the expected response against the typical response of the smart garbage disposal system. Ultrasonic sensors, servo motors, solar panels, and the display LCD were put to the test for confirmation of their response.

| Table 2: Expected response versus typical response. | |||

| ID | Test Features | Expected Action | Typical response |

| SD-1 | Sensor Ultrasonic (HC-SR 04) | Detect objects (garbage) right in front of it with an optimal distance of a minimum of 5cm and a maximum of 50cm. | Successful |

| SD-2 | First operation of Servo Motor | Automatically opens the smart dustbin cover with a certain delay time. | Successful |

| SD-3 | Second operation of Servo Motor | Automatically close the smart dustbin cover, after the opening time delay is over. | Successful |

| SD-4 | Source Voltage (9volt battery) | Saves power to flow on the Arduino and lasts approximately 2-4 weeks. | Successful |

| SD-5 | Ultrasonic (HR=SR04) | Detect object (garbage) inside the bin and remain closed indefinitely until offloaded | Successful |

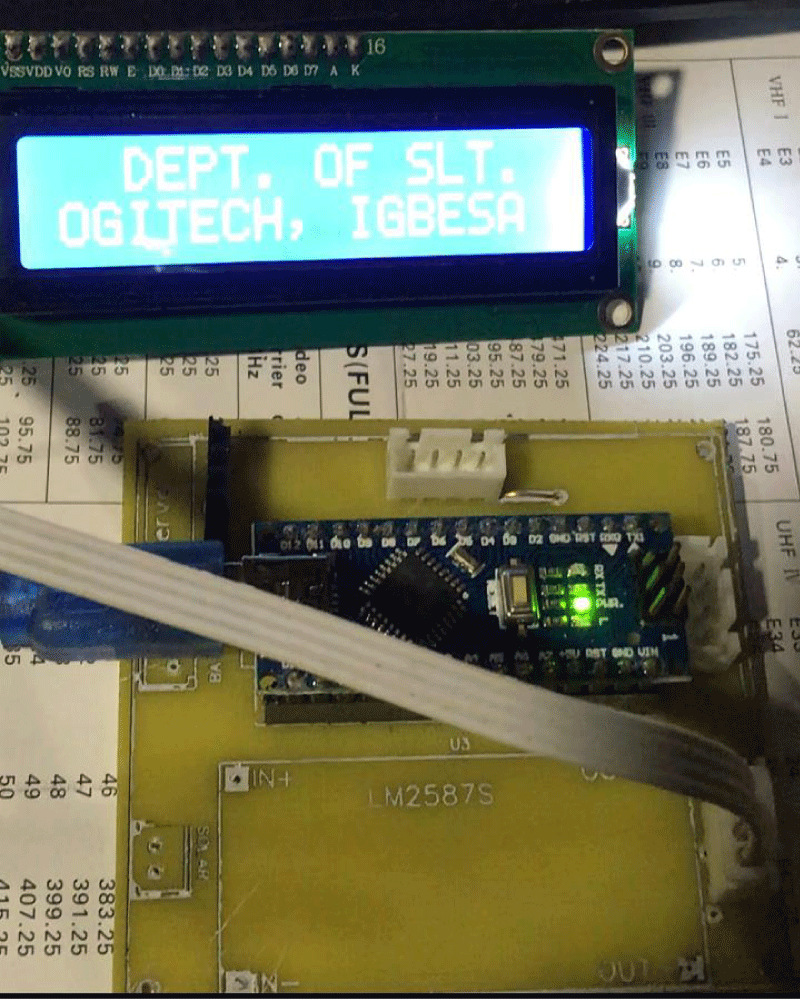

When the power switch is high, the LCD shows welcome messages in the order shown in Table 3. After the display of the welcome message, the dustbin is ready for use. Then, the lid closes, and the LCD displays a “BIN CLOSED” message (Figure 9).

| Table 3: Welcome messages displayed. | ||

| Display stage | Message type | Preset output display |

| 1st | Project topic | |

| 2nd | Name and Matric. No. of the student | |

| 3rd | Name of Supervisor | |

| 4th | State of the Bin | Closing bin |

| 5th | ||

Figure 9: Showing display when the lid is closed.

Whenever a waste disposal agent moves a distance of 5 cm to 50 cm toward the ultrasonic sensor’s field, the LCD displays “BIN OPENING” and the lid opens up to allow waste to be dropped inside the can. Once the agent finished dropping the waste, the lid closes again and shows a “CLOSED” message.

The process continues until the inner sensor detects that the bin has full. It then displays “BIN FULL CLOSED PLEASE EMPTY ME” (Figure 10). This message locked up the bin indefinitely until the whole of the waste is been emptied. It then repeats all the stages again.

Figure 10: Showing display when the trash bin is full.

The usage is indefinite since it charges itself automatically using a solar panel mounted on the body. Though, in the absence of sunlight, there may not be enough photons dropped on the solar panel to be converted to electricity that charges the battery.

In such a situation, the trash bin is connected to the main electric power source for charging. The charging may take approximately 4 to 5 hours or more before being fully charged. Having fully charged, the time to run down depends on how frequently it is being used (that is, the time to drain the battery is not easily measurable).

A solar-powered smart garbage disposal device was designed and constructed using Arduino Nano programmable board. The device generates its power source from electricity and solar system. It opens the lid on the presence of the waste disposal agent around the ultrasonic sensor at a distance between 5 cm to 50 cm and displays “bin opening”. It closes the lid if it does not sense anything and displays “bin closed”. The lid is locked down when the bin is filled up with debris at a distance of 5 cm from the waste within it. It is recommended for further research that an Internet module be added to this device to open an interface for the Internet of Things (IoT) between either mobile phones, waste disposal agents’ ground stations, or the cloud.

- Hong I, Park S, Lee B, Lee J, Jeong D, Park S. IoT-based smart garbage system for efficient food waste management. ScientificWorldJournal. 2014;2014:646953. doi: 10.1155/2014/646953. Epub 2014 Aug 28. PMID: 25258730; PMCID: PMC4166430.

- Chinaza GA, Hannington T, Chibueze GA, Igwe SV and Amagwula OI. Industrial waste management, treatment, and health issues: wastewater, solid, and electronic wastes. European Academic Research, 2020; 8(2):1081-1119.

- Satyamanikanta SD, Narayanan M. Smart garbage monitoring system using sensors with RFID over Internet of Things. Journal of Advanced Research in Dynamical and Control Systems. 2017; 9(6):133-139.

- Perera C, Zaslavsky A, Christen P, Georgakopoulos D. Sensing as a service model for smart cities supported by Internet of Things. 2013; 25(1): 81–93.

- Thompson AF, Afolayan AH, Ibidunmoye EO. Information science, computing and telecommunications, 2013; 206.

- Yusof MN, Jidin AZ, Rahim MI. Smart garbage monitoring system for waste management. MATEC Web of Conferences 97. 2017; DOI: 10.1051/matecconf/20179701098

- Nightingale F. Selected Writings of Florence Nightingale. 1st ed. Lucy Ridgely Seymer (New York: The Macmillan Co.). 1954; 38287.

- Chowdhury B, Chowdhury MU. RFID-based Real-time Smart Waste Management System, in Australasian Telecommunication Networks and Applications Conference. 2007; 175-180.

- Chattopadhyay P, Chaudhuri R, Dasgupta S, Priya G. Smart garbage monitoring system. International Journal of Engineering Research & Technology (IJERT). 2017; 6(5):2278-0181. [Cited August 27, 2022] http://www.ijert.org.

- Zanella A, Bui N, Castellani A, Vangelista Lsz, Zorzi M. Internet of Things for smart cities. IEEE Internet Things J. 2014; 1(1): 22-32.

- Yujie W, Yanzhu X, Bingchang Z, Junhong Z, Xinpu S. The design and implementation of the smart trash can based on the Internet of Things, Journal of Physics: Conference Series 1550 (2020) 022003 IOP Publishing doi:10.1088/1742-6596/1550/2/022003