More Information

Submitted: March 31, 2023 | Approved: May 24, 2023 | Published: May 25, 2023

How to cite this article: Kileti P, Barkwill B, Mahajan D. Understanding RNG Gas Quality through Execution at Newtown Creek WRRF RNG. Ann Civil Environ Eng. 2023; 7: 017-023.

DOI: 10.29328/journal.acee.1001051

Copyright License: © 2023 Kileti P, et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Keywords: Renewable natural gas; Newtown Creek WRRF; Gas quality; Gas blending; Gas distribution

Understanding RNG Gas Quality through Execution at Newtown Creek WRRF RNG

Pradheep Kileti1*, Brian Barkwill1 and Devinder Mahajan2

1National Grid, Future of Heat Engineering, Melville, NY 11747, USA

2Institute for Gas Innovation and Technology, Stony Brook University, Stony Brook, NY 11794, USA

*Address for Correspondence: Pradheep Kileti, National Grid, Future of Heat Engineering, Melville, NY 11747, USA, Email: [email protected]

With each passing year a new record for global emissions is set (1) and policymakers and utility companies must embrace all avenues for decarbonization of energy. Universal adoption of electrification for every building and home by 2050 (2) is not practical, a balance must be struck between an equitable transition to cleaner energy supplies and ensuring uninterrupted, safe delivery of energy to utility customers. Renewable Natual Gas (RNG) is a molecule-for-molecule replacement of traditional geological natural gas with tangible life cycle emissions reductions. California continues to lead the way, initially starting with the low carbon fuel standard (LCFS) which aimed to reduce the carbon intensity of transportation fuel, and subsequently, Senate Bill 1440, which established RNG procurement goals including 12% RNG by 2030 (3). Other States are starting to adopt similar changes such as Oregon’s Senate Bill 98 and Colorado’s Senate Bill 21-264. As utilities attempt to transition the energy network, they must never compromise system safety and reliability. Recognizing that raw biogas has dangerous levels of contaminants of concern (COC) and must be conditioned to pipeline quality, its important utility companies better understand the methods with which methane is extracted and the testing protocols used to confirm performance. This paper highlights the equipment, processes, and testing regime National Grid and its partner the New York City Department of Environmental Protection (NYC DEP) deployed as part of its Newtown Creek RNG project, which successfully began injecting RNG into the NYC gas distribution network in October 2022.

Climate change is the defining challenge of the 21st century. The science is clear that we must act now to reduce greenhouse gas (GHG) emissions as fast as possible to avoid the worst effects of climate change. With ambitious goals being set around the county, as well as around the world, it’s imperative that tangible methane reductions are realized within the next decade in order to achieve publicly stated goals for 2050. According to the UN Environment Program Climate & Clean Air Coalition, with each passing year, we set new record increases in global emissions [1]. Policymakers cannot let perfection be the enemy of good, it’s time to embrace all pathways toward decarbonization. Policy-wise, California continues to lead the way. Senate Bill 1440 established RNG procurement goals for gas utilities, including 12% by 2030 [2]. Other states followed in their wake, with similar legislation such as Oregon’s Senate Bill 98 and Colorado’s Senate Bill 21-264 having been recently passed.

In April 2021, the New York City Mayor’s Office of Sustainability issued the “Pathways to Carbon-Neutral NYC” report [3]. The report highlighted the challenges of electrification for 40% - 70% of the buildings in New York City and cited the role low-carbon fuels have to play for the City to meet its climate goals. National Grid conducted its own analysis, which found that in NAUSA’s operating territories (New York and Massachusetts) it is technically difficult and/or impossible to electrify 30% - 70% of building space in the urban areas of New York City and Boston and 5% - 40% outside of those major cities [3]. Considering that access to reliable heat is required for human health and required by law in cold climates, decarbonization of heat is not yet a one solution fits all problem.

National Grid’s Fossil Free Vision targets a hybrid approach to decarbonizing the heating sector along with targeted electrification and significant improvements to energy efficiency. Similar to the decarbonization of electricity from wind and solar, gas networks can be used to heat homes with alternative fuel supplies such as renewable natural gas and green hydrogen. Hydrogen blending in gas pipeline networks [4,5] has become the primary focus of research in the decarbonization of heat. Hydrogen has substantial benefits and offers incredible long-term promise as a stand-alone heating fuel, however, there are real equipment and production limitations to realizing that potential in the next ten years. Renewable natural gas is a critical piece of the puzzle, potentially offsetting up to 95 of residential heat, reducing emissions by up to 235 million MT of CO2 eq [6]. Beyond its decarbonization value, RNG can help to meet localized demand for pipeline natural gas.

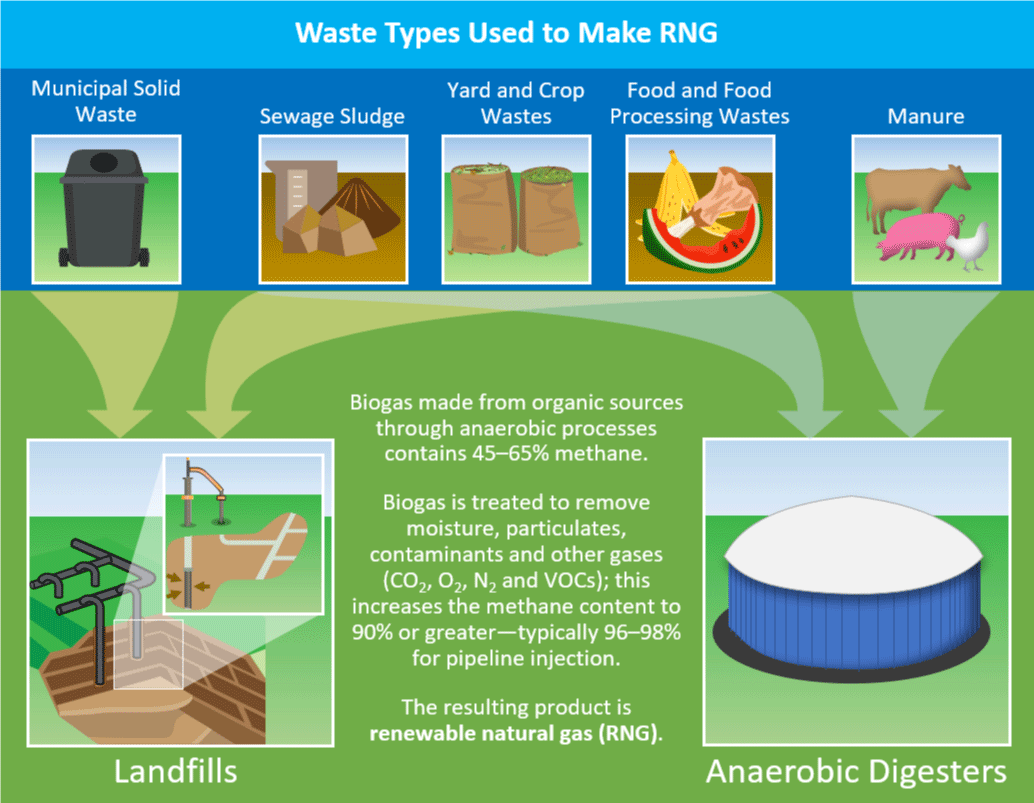

The American Gas Association (AGA) broadly defines RNG as “pipeline-compatible gaseous fuel derived from biogenic or other renewable sources that have lower lifecycle carbon dioxide equivalent (CO2e) emissions than geological natural gas” [6]. According to the US Department of Energy, most RNG is produced via anaerobic digestion (AD) of organic material, a process in which microorganisms break down organic matter in the absence of oxygen [7]. Typical feedstocks for biogas production via AD, include wastewater sludge, food waste, animal manure, and landfill waste. AD processes yield between 45% - 65% methane, with the balance predominately compromising CO2, H2S, and water vapor. To be suitable for introduction to the gas distribution network, the raw biogas must be processed to increase methane content and remove unwanted constituents. Thermal gasification of biomass can also produce RNG under appropriate conditions, where synthesis (or syngas) gas is generated and conditioned to meet the pipeline quality specifications [8]. The final pathway is power-to-gas, where electricity is used to produce hydrogen. The hydrogen is then fed to a methanator, where H2 and CO2 are converted to methane (CH4) and water. Since the hydrogen used is produced from a carbon-free source, such as wind or solar, the resulting methane is considered renewable [9] Figure 1.

Figure 1: EPA sources of biogas for RNG.

Even the smallest change to gas networks and gas supply composition must be vetted for impacts on reliability and safety. A case in point is the introduction of Marcellus Shale into gas distribution networks, where heavier hydrogen carbons such as ethane and propane caused the energy value of the gas to increase compared to the gulf coast supply, introduction of alternative fuels such as renewable natural gas and hydrogen must be vetted thoroughly to maintain homogeneous gas composition. In recent years, efforts such as the Northeast Gas Association Interconnect Guide for Renewable Natural Gas (RNG) [10], have tried to quantify and manage risks of various constituents of concern (COCs) within raw biogas.

Gas quality standards are set and enforced to ensure the gas delivered will not negatively affect customer equipment or generate excessive levels of dangerous byproducts such as carbon monoxide. These standards are often set by regulatory pipeline tariffs and their limits have been determined through years of operational experience and sound science. A utility tariff defines terms and conditions for accepting, transporting, and receiving natural gas, including specifications for gas quality and how an energy provider charges the customer. Quality regulations also ensure that gas will not damage or degrade gas system equipment [11]. Tariffs specifying acceptable ranges for gas quality can be found on any interstate pipeline website.

Beyond the tariff requirements, the following are some of the more common COCs that need to be considered:

1) Sulfur

2) Ammonia

3) Volatile Organic Compounds

4) Siloxanes

5) Halogenated compounds

6) PCBs and Pesticides

7) Aldehydes and Ketones

8) Moisture

If RNG is to fulfill its potential as a decarbonized heating source, it is imperative that utility companies better understand the impacts of each COC and see proof of concept behind various conditioning systems and gas interconnect systems which act as the utility’s last line of defense in preventing out of spec gas from entering the pipeline.

National Grid has been at the forefront of the renewable natural gas space for decades. In 1982, National Grid implemented one of the first RNG projects in the country, accepting biogas from Fresh Kills landfill and conditioning it, and injecting it into the gas distribution network in Staten Island [12]. The facility operated for nearly 40 years prior to its closing in 2021 as a result of depressed gas production. In recent years, National Grid partnered with the New York City Department of Environmental Protection and Waste Management to produce RNG from wastewater sludge and food waste and inject it into the local distribution system.

Newtown Creek water resource recovery facility

Newtown Creek Wastewater Resource Recovery Facility (WRRF) is the largest wastewater treatment plant in New York City. Servicing over 1.3 million people each day throughout Northwest Brooklyn, Southwest Queens, and Lower Manhattan, the facility has a design flow capacity of 310 million gallons per day (MGD) with a wet weather capacity of over 700 MGD.

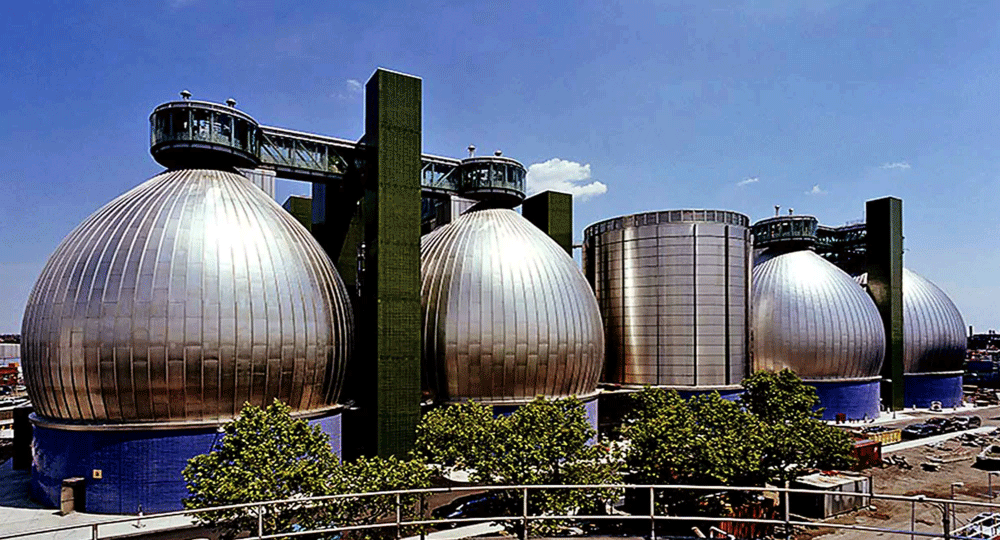

Solids are collected via high-rate sedimentation tanks and thickened to produce sludge. Wastewater sludge is rich in organic material, making it an ideal feedstock for anaerobic digestion. As part of a major capital improvement that was completed in 2010, [13] NYC DEP erected eight (8) egg-shaped anaerobic digesters to break down over 1.4 million gallons of sludge each day and produce biogas onsite [14]. The City has also partnered with Waste Management to collect food waste and produce engineered bio-slurry, which can be co-digested alongside sludge within the digesters [15]. The food waste program has expanded up to 250 tons per day of organic waste, with additional plans to expand the program currently being considered by the City.

National Grid partnered with NYCDEP to mutually benefit from the biogas produced on site, which historically has only beneficially used only a portion of the biogas produced on site for boiler heating. National Grid owns the conditioning system, which will take all excess gas supply and condition it to pipeline quality prior to injecting it into the local Greenpoint, New York gas distribution network.

Prior to selecting any single conditioning system, robust gas sampling of the raw gas was conducted to identify an optimal treatment system. Table 1 below highlights containments often founds in raw biogas from wastewater sludge. Raw gas values determined by a third-party laboratory and the National Grid limit. The sampling and testing methods are outlined in Section 3.

| Table 1: Contaminants of concern. | |

| Component | Present in DEP Raw Gas |

| Hydrogen Sulfide (H2S) | Yes |

| Total Sulfur | Yes |

| Total Siloxanes | Yes |

| TOTAL KETONE | Yes |

| TOTAL HALOCARBON | BDL |

| TOTAL VOCs/SVOCs/PAHs | Yes |

| TOTAL PAHs | Yes |

| TOTAL SVOCs | Yes |

| TOTAL VOCs | Yes |

| Mercury | Yes |

| Ammonia | Yes |

| Aldehyde | Yes |

| Total PCB | BDL |

| Total Pesticides | BDL |

| Total Metals | Yes |

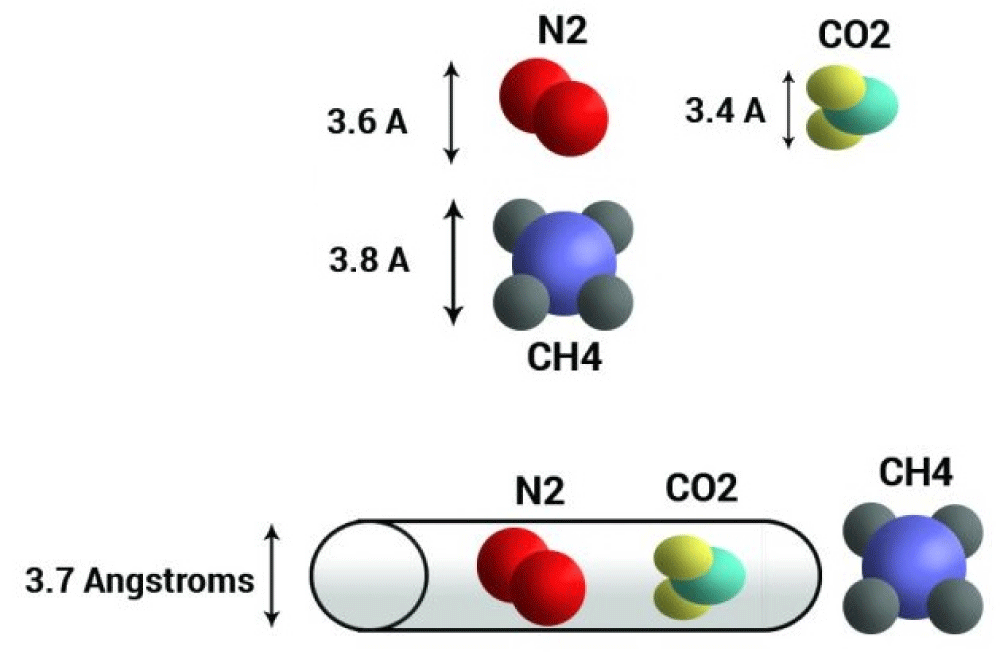

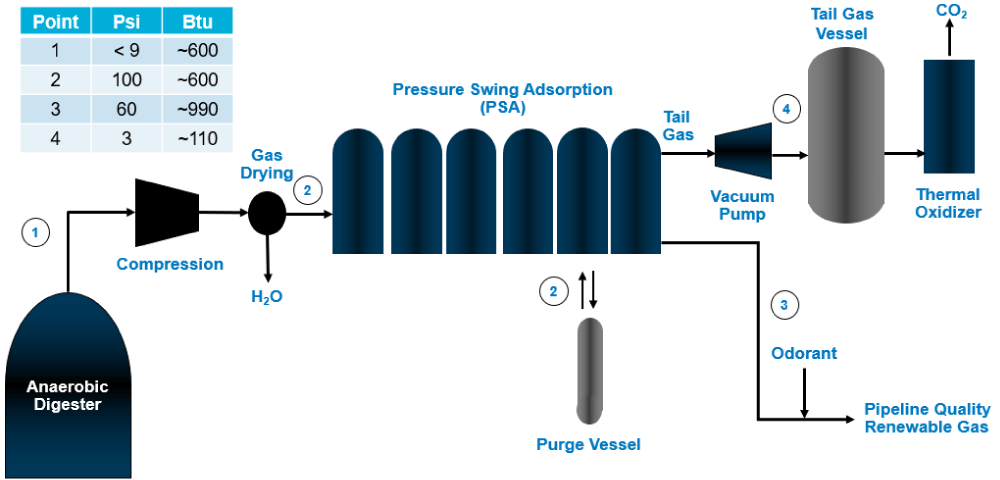

For this application, a pressure swing adsorption (PSA) system was utilized to enhance the quality of the biogas. As a technology, PSA is used to separate some gas species from a mixture of gases under pressure according to the species’ molecular characteristics and affinity for an adsorbent material (Figure 2). Engineered media, typically using special adsorptive materials such as zeolites, are used as a molecular sieve with the pore size of the media being used to separate gases at high pressures. Conditioning Gas, also known as Sales gas, is removed from the PSA vessels and then the process then swings to low pressure, allowing the adsorbed gases to desorb from the adsorbent material [16] Figure 3.

Figure 2: Photos of Newtown Creek WRRF egg shaped digesters.

Figure 3: Guild associates image: Media pore size relative to key gas constituents in biogas.

At Newtown Creek, a vacuum pump is used to remove all the tail gas, or waste gas, which is fed to a thermal oxidizer. This process wastes about 5% - 10% of the methane product to ensure high quality in the sales gas while also allowing the gas supply to burn properly Figure 4.

Figure 4: Newtown Creek process flow diagram.

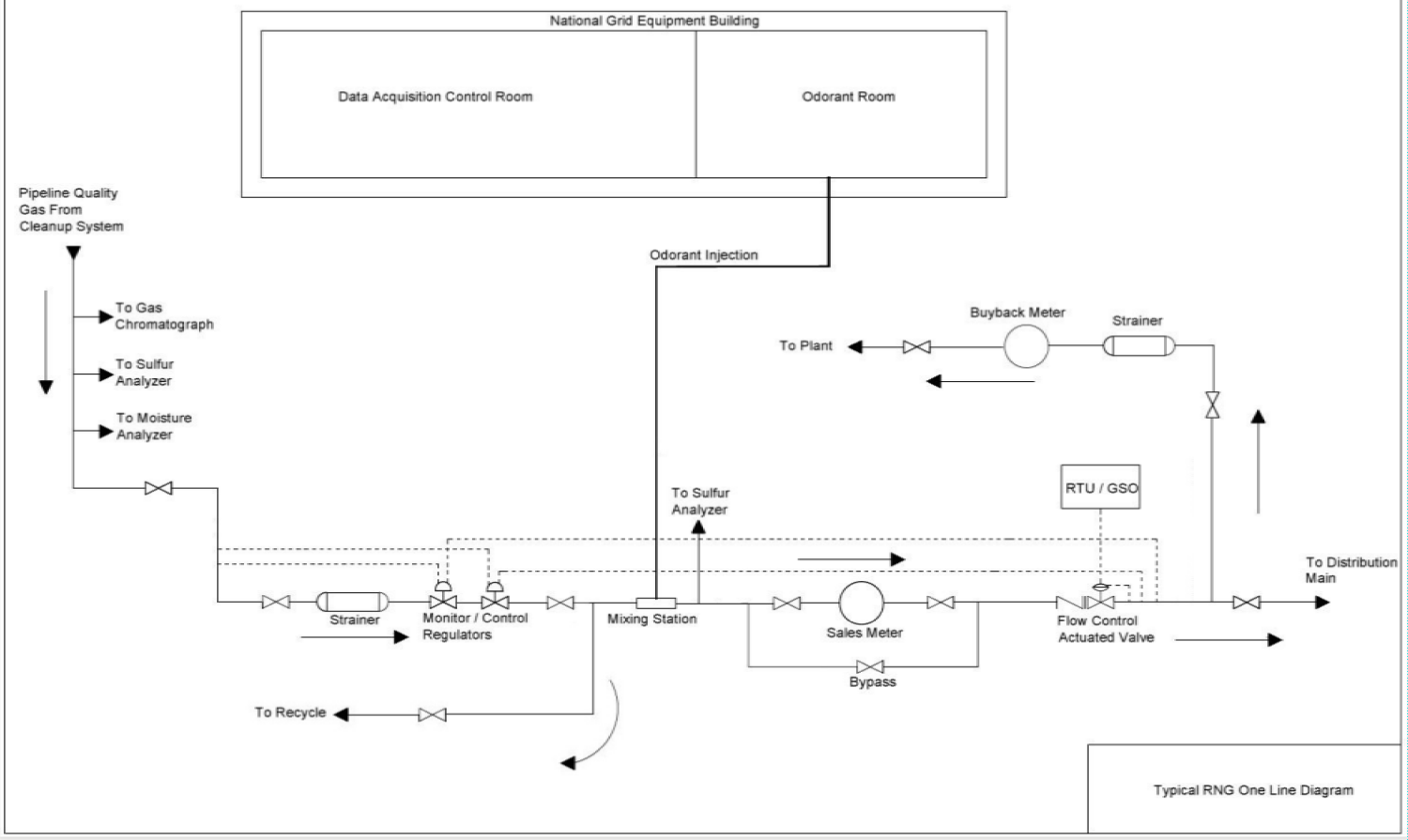

Downstream of the conditioning system, National Grid installed a standard RNG interconnect system (Figure 5), fitted with a gas chromatograph, sulfur analyzer, moisture analyzer, odorant system, pressure regulation, gas meter, and process control valves that open and close to allow flow into the distribution network depending upon the gas quality of the treated gas. Odorant is stored according to local building code requirements in a building/enclosure. The system was extensively reviewed with National Grid’s process safety team to ensure there are no common-cause failures that could result in out-of-spec gas being allowed to enter the gas distribution network.

Figure 5: National Grid installed a standard RNG interconnect system.

Sampling procedure

The product gas out of the pressure swing adsorption system was sampled and analyzed to evaluate the system’s performance. For each round of sampling, triplicate samples were taken for every test for redundancy purposes. Gas sampling was conducted by the National Grid’s gas laboratory and worked with another laboratory that managed/performed the analytical work. Each round of sampling evaluated the concentrations of the following gas components:

- Major components ‐ C1 to C6+ hydrocarbons, N2, O2, H2, CO, CO2

- Volatile organic compounds (VOCs) and halocarbons

- Sulfur compounds

- Siloxanes

- Ammonia

- Aldehydes

- Trace metals (including mercury)

- Semi-volatile organic compounds (SVOCs)

- Polyaromatic hydrocarbons (PAHs) and alkyl PAHs

The sampling and analytical procedures are described below:

Gas composition and hydrocarbons: A pre-cleaned 6L sulfinert Summa canister was used to collect gas samples for the gas composition test as well as the VOC, halocarbon, ketone, and sulfur compounds analyses. Each summa canister was under a vacuum for 20 minutes in accordance with EPA method TO-15.

A gas chromatograph with a thermal conductivity detector and flame ionization detector following (GC/TCD/FID) EPA reference methods 3C and TO‐3 was used for the gas composition analysis. The VOC, halocarbon, and ketones followed EPA TO-15, using a gas chromatograph/mass spectrometer (GC/MS) to detect concentrations. The Sulfur analysis was completed using a gas chromatograph with a sulfur chemiluminescence detector (GC/SCD) following ASTM D5504.

Siloxanes: The EPA Method 0040 (modified) called for new pre-cleaned 1L Tedlar bags to be used when collecting the gas samples. A gas chromatograph/mass spectrometer (GC/MS) was used to conduct the siloxane analysis in accordance with ASTM D8230.

Ammonia: The NIOSH method 6014 (modified) was implemented using a dry gas meter for volume measurement. The gas samples were collected in sulfuric acid-coated silica gas tubes and analyzed using a visible adsorption spectrophotometer.

Aldehydes: The sampling and testing procedure followed the guidelines from EPA method TO‐11A. DNPH cartridges were used to collect the gas samples and a dry gas meter was used for volume measurement. The tubes were desorbed and analyzed by high-pressure liquid chromatography (HPLC) using UV detection.

Trace Metals: The gas samples were collected and tested in accordance with EPA Method 29 (Modified). A sampling train was assembled, the major components of which are outlined below:

- A probe assembly

- The first and second impingers initially contained 100 mL each of 5% nitric acid solution to collect metals

- The third impinger was initially empty

- The fourth impinger contained silica gel

- A pre‐calibrated dry gas meter was connected to the outlet of the sample train and measured the volume of gas sampled

The contents of the first three impingers were combined. Triplicate rinses of the impingers and connecting glassware were performed with 0.1 N nitric acid and combined with the impinger solution sample. A blank train was prepared, and samples were recovered in a manner identical to the test sampling trains. Sample analyses were performed using inductively coupled plasma mass spectrometry (ICP‐MS) in accordance with the analytical method EPA 6020B.

Total mercury: Mercury samples were collected on gold-coated adsorbent tubes specifically designed for detecting low levels of mercury in gas streams following the procedures detailed in ASTM D5954. A dry gas meter was used for volume measurement. The samples were analyzed in accordance with ASTM D5954 using atomic adsorption spectroscopy (AAS).

SVOCs, PAHs, and Alkyl PAHs: Semi‐volatile organic compounds (SVOCs), poly aromatic hydrocarbons PAHs, alkyl PAHs, polychlorinated biphenyls (PCBs), and pesticides were collected using a modified sampling train and sampling procedures outlined in Environment Canada Report EPS 1/RM/2. The major components of the sampling train were as follows:

- A probe assembly

- Amberlite XAD‐2 sorbent trap

- The first and second impingers contained 100 mL of distilled water

- The third impinger was initially empty

- The fourth impinger contained silica gel

- A pre‐calibrated dry gas meter was connected to the outlet of the sample train and measured the amount of gas sampled

Two separate trains per sample were required to capture all compounds. SVOCs were collected on one sample train and the remainder of the compounds were on the second sample train. All test trains and auxiliary glassware were pre-cleaned as outlined in Environment Canada EPS 1/RM/2. A blank train was prepared and treated in a manner identical to the test trains. Analyses were completed using the following reference methods and instrumentation:

- SVOC’s ‐ Reference method EPA 8270D using gas chromatography with mass spectrometry (GC/MS)

- PAH’s and Alkyl PAH’s ‐ Reference method EPA 8270D using selective ion monitoring gas chromatography with mass spectrometry (SIM GC/MS)

Without demonstrated gas quality validated by a third-party lab, the conditioned gas could not be injected into the distribution system. A temporary thermal oxidizer was brought to the site to combust the conditioned gas as the commissioning of the odorant system was performed and gas samples were collected and analyzed.

The startup of the feed gas compressor and the pressure swing adsorption system began on July 26th, 2022. For several weeks, the system pulled biogas from the Newtown Creek digesters, conditioned the biogas, and flared both the sales and tail gas produced by the system. Gas sampling for third-party validation began on August 18th and was completed on September 1, 2022. The sales gas quality was measured by the onsite gas chromatograph and the third part lab showed exceptional quality. The methane content of the sales was recorded to be 98.336% or greater throughout the fifteen-day gas sampling window. The lowest energy content recorded was 997.4, well above the 980 requirements held by National Grid, which was required to meet all regulatory requirements for blending RNG in this location. Inert gases such as Nitrogen and Oxygen were acceptable for pipeline injection, however, elevations were elevated in the initial measurement. Gas Quality determined this was due to air intrusion given the ratio measured. A revised collection process using a sample collected in a steel cylinder with inlet and outlet valves was used in lieu of a summa canister.

Table 2 shows the National Grid not to exceed limits for each COC and the results of each round of testing

| Table 2: Third party lab results. | |||||

| Component | Round1 Below Limit (Y/N) | Round2 Below Limit (Y/N) | Round3 Below Limit (Y/N) | NationalGrid Limit | Units |

| Hydrogen Sulfide (H2S) | Y | Y | Y | 4.00 | ppmv |

| Total Sulfur | Y | Y | Y | 18.00 | ppmv |

| Total Siloxanes | Y | Y | Y | 0.50 | mg/m3 |

| TOTAL KETONE | Y | Y | Y | 103.00 | ppbv |

| TOTAL HALOCARBON | Y | Y | Y | 100.00 | ppbv |

| TOTAL VOCs/SVOCs/PAHs | Y | Y | Y | 471,000 | ppbv |

| TOTAL PAHs | ppbv | ||||

| TOTAL SVOCs | ppbv | ||||

| TOTAL VOCs | ppbv | ||||

| Mercury | Y | Y | Y | 80.00 | ng/m3 |

| Ammonia | Y | Y | Y | 10.00 | ppmv |

| Aldehyde | Y | Y | Y | 1.00 | ppbv |

| Total PCB | Y | Y | Y | 1.00 | mg/m3 |

| Total Pesticides | Y | Y | Y | 1.00 | ppbv |

| Total Metals | Y | Y | Y | 213.00 | ug/m3 |

The results of the third-party analysis showed each COC was properly stripped below gas tariff requirements. On September 9th, National Grid Gas Quality experts approved the supply for pipeline injection. On October 12, 2022, National Grid and NYC DEP successfully began injecting RNG into the Greenpoint, NY gas distribution network.

As RNG grows in adoption and uses in the heating network, its imperative utilities become comfortable with the processes and systems that validate performance and confirm gas quality. The Newtown Creek RNG system utilized a pressure swing adsorption system that was operated for several weeks to test performance, with gas consumption of a distribution network simulated with a temporary thermal oxidizer. The methane content of the sales gas was recorded to be 98.336% or greater throughout the fifteen-day gas sampling window, successfully demonstrating the system stripped methane from the biogas. Three rounds of sampling, with each sample being triplicated, were conducted over 15 days to ensure all gas quality requirements were met. The results showed all the Contaminants of Concern identified as present in the raw gas samples, were all conditioned below National Grid Tariff requirements. On September 9th, National Grid Gas Quality experts approved the supply for pipeline injection and on October 12, 2022, National Grid and NYC DEP successfully began injecting RNG into the Greenpoint, NY gas distribution network. In addition to 24/7 monitoring via a gas chromatograph, sulfur analyzer, and moisture analyzer, additional third-party lab tests will be conducted to validate performance. Monthly samples will be taken for the next twelve months, supported by internal gas quality checks via the Gas Lab’s gas chromatograph.

Funding

This research was funded internally by National Grid.

Data availability statement

Detailed research data is available upon request.

The primary personnel at National Grid responsible for the successful execution of this project are as follows. Future of Heat (Melissa Mauro); Project Management (Richard Swedborg, Ryan Wood, Saed Abdul Hamid, Jay Doodnath); Gas Quality (Daniel Settle), Instrumentation and Regulation (Sebastian Gomez, David Dinota), Materials Lab (Tom Savino); Gas Lab (Devon Bennett, Leo Tyrrell, Akeil Belfon, Irina Paster). Special thanks to Ortech Consulting, ALS Global Laboratories, and Ohio Lumex who conducted the third-party analysis.

Gas Engineering (Dennis Leyble, Brian Bermingham) that would be great.

- UN Environment Programme & Climate & Clean Air Coalition. Global Methane Assessment: 2030 Baseline Report - Why Act Now: a new era for accelerated implementation. https://static1.squarespace.com/static/53a09c47e4b050b5ad5bf4f5/t/63e51c1cc51031116b522631/1675959325919/2022_Methane-baseline-summary_0.pdf

- California Public Utility Commission. CPUC Sets Biomethane Targets for Utilities. https://www.cpuc.ca.gov/news-and-updates/all-news/cpuc-sets-biomethane-targets-for-utilities

- National Grid Group. Our vision for a fossil-free future," April 2022. [Online]. Available: https://www.nationalgrid.com/us/fossilfree.

- Mahajan D, Tan K, Venkatesh T, Kileti P, Clayton C. Hydrogen Blending in Gas Pipeline Networks-A Review. Energies. 2022; 3582: 15. https://doi.org/10.3390/

- Loughran J. Britain's gas grid preparing to accept 20 percent hydrogen mix by 2023," Engineering & Technology 2022. https://eandt.theiet.org/content/articles/2022/01/britain-s-gas-grid-preparing-to-accept-20-per-cent-hydrogen-mix-by-2023/.

- American Gas Foundation study Prepared by ICF. Renewable Sources of Natural Gas: Supply and Emissions Reduction Assessment. 2019.

- Us Department of Energy. Renewable Natural Gas Production. https://afdc.energy.gov/fuels/natural_gas_renewable.html.

- IEA Bioenergy. Status Report of Thermal Gasification of Biomass and Waste 2021. https://www.ieabioenergy.com/wp-content/uploads/2022/03/Status-Report2021_final.pdf

- Oxford Institute of Energy Studies. Power-to-Gas: Linking Electricity and Gas in a Decarbonizing World?. https://www.oxfordenergy.org/wpcms/wp-content/uploads/2018/10/Power-to-Gas-Linking-Electricity-and-Gas-in-a-Decarbonising-World-Insight-39.pdf

- Wilson R. Interconnect guide for emerging fuels into energy delivery networks. Northeast Gas Association & GTI Energy, 2022.

- Mauro M. Incorporating RNG into the Gas System," American Institue of Chemical Engineers. https://www.aiche.org/resources/publications/cep/2021/september/incorporating-rng-gas-system

- Ascher K, O’Connell F. From Garbage to Energy at Fresh Kills. The New York Times. https://archive.nytimes.com/www.nytimes.com/interactive/2013/09/15/nyregion/from-garbage-to-energy-at-fresh-kills.html

- L’Observatoire International. 2009 AL Design Awards: Newtown Creek Wastewater Treatment Plant, Greenpoint, Brooklyn, N.Y. https://www.architectmagazine.com/awards/al-design-awards/2009-al-design-awards-newtown-creek-wastewater-treatment-plant-greenpoint-brooklyn-n-y_o

- LevineL. Digester Eggs bring “elegant combination of engineering and art” to Newtown Creek. Greenpointers. https://greenpointers.com/2017/10/31/digester-eggs-bring-elegant-combination-engineering-art-newtown-creek/

- Waste Management Fact Sheet. WM Varick 1 CORe – Newtown Creek Co-Digestion Project. https://www.wm.com/NYCMA/WMCORe%20varick-factsheet%20073114.pdf

- Guild Associates. Inc., Molecular Gas Adsorbent Technology. https://www.guildassociates.com/gas-processing-systems/mgtech/