More Information

Submitted: November 17, 2022 | Approved: November 22, 2022 | Published: November 23, 2022

How to cite this article: Abara L, Evaluation of pulp and paper-making potential of Acacia melanoxylon based on chemical composition grown at Chencha, Ethiopia. Ann Civil Environ Eng. 2022; 6: 066-070.

DOI: 10.29328/journal.acee.1001044

Copyright License: © 2022 Abara L. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Keywords: Chemical composition; Tree height levels; Acacia melanoxylon; Pulp and paper

Evaluation of pulp and paper-making potential of Acacia melanoxylon based on chemical composition grown at Chencha, Ethiopia

Lamesa Abara*

Ethiopian Forest Development, Forest Products Innovation Center, Addis Ababa, Ethiopia

*Address for Correspondence: Lamesa Abara, Ethiopian Forest Development, Forest Products Innovation Center, Addis Ababa, Ethiopia, Email: [email protected]

The study aimed to examine the chemical composition of Acacia melanoxylon wood as a potential raw material for pulp and paper manufacturing. Samples of Acacia melanoxylon were taken systematically based on tree height at the bottom (10%), middle (50%), and top (90%) of market height. The sample was sorted, dried, milled, and sieved, and all chemical compositions were determined by the standards outlined in ASTM except cellulose and hemicellulose, which were determined by the Kurschner-Hoffer and alkali extraction methods, respectively. The results of the study showed that the overall average values of chemical composition along tree height levels were 45.02%, 21.94%, 23.79%, 5.52%, 3.24% and 0.48% for cellulose, hemicellulose, Klason lignin, hot-water solubility, alcohol-benzene extracts, and ash content, respectively. Except for hot-water extractives, the chemical composition of the bottom and top portions differed significantly. Generally, this study suggests that the chemical composition of Acacia melanoxylon wood is well suited for pulp and paper production.

Global paper consumption is estimated at 400 million tonnes annually and is projected to reach 500 million tonnes by 2020 [1]. Global paper and board consumption is steadily increasing for many reasons, including population growth and industrialization in developing countries [2].

The pulp is produced from hardwoods, softwood and agricultural residuals. Hardwood and softwood pulp account for 95% of total world pulp production, and the remaining 5% comes from non-wood raw materials, mainly agricultural residues and grasses [3]. In Ethiopia, the demand for paper increases by 10 percent each year [4]. For instance, in 2003 average annual domestic production of paper was 7,266 tons, while in the same year, 127,132 tons of paper have been imported which means the average total supply of paper during the period under consideration was 134,398 tons per annum, of which only about 5% was locally produced. Hence, the consideration of some fast-growing wood species in the Ethiopia forest as a potential raw material for pulp production is the right step towards meeting the demand for pulp and paper.

The genus Acacia consists of about 1,300 species in three subgenera: Acacia, Aculeiferum, and Phyllodineae. Over 95% of these species are endemic to Australia and they are referred to collectively as ‘Australian acacias’ [5]. A. melanoxylon locally known as ‘’Omedla’’ is one of the most important multipurpose tree species and widely distributed in cooler and wetter upland areas, Moist and Wet Kolla Weyna Dega and Dega agroclimatic zones of Ethiopia. This species has been mainly used for firewood, charcoal, light construction, plywood, flooring, fence posts, shade, ornaments, windbreaks, gum, and tannery. It has the ability to coppice from damaged stems and grow rapidly on various soils [6].

Although there are many indigenous and exotic wood species in Ethiopia, imports of forestry products, including pulp and paper, from other countries have increased rapidly [7]. This is due to a lack of information on wood and wood-based technical characteristics or no know-how on their quality, technological alternatives, and less value-added processing which resulted in over-harvesting and degradation of the existing forests both in quality and quantity [7,8].

Prior to recommending any wood species for pulp and paper production, adequate information on chemical composition is vital, since it affects the quality of pulp and pulp products [9]. Even though the wide range of use of A. melanoxylon, its fast growth, its ability to coppice, and its adaptation to different parts of Ethiopia, its quality of pulp and paper products were not known. Therefore, the aim of this study was to investigate the chemical compositions of A. melanoxylon in the context of potential raw material quality evaluation of pulp and paper production.

Description of the study area

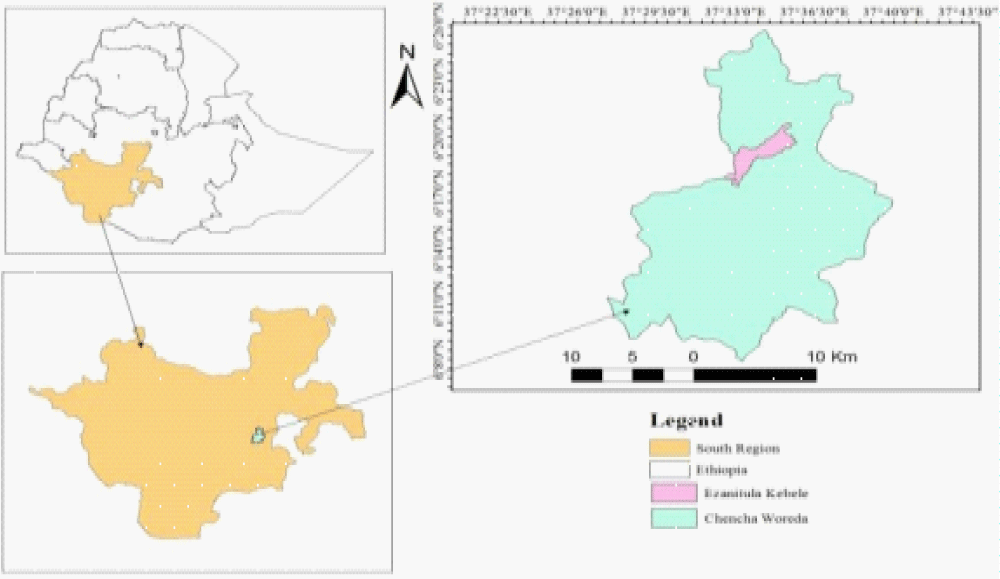

The study sample trees were taken from Chencha district Ezanitula kebele of South Nation Nationality People Region, which is located 37 kilometers North of Arbaminch, and 500 kilometers from the capital city of Addis Ababa. It is located 37o 26’0” - 37o 40’0”E and 6o 8’0”- 6o 26’0”N longitude and latitude respectively (Figure 1). The annual distribution of rainfall in the area ranges from 900 mm to 1200 mm [10] Table 1.

Figure 1: Map of the study area is placed inappropriate place please put it under the description of the study area.

| Table 1: Standard followed for chemical composition analysis. | ||

| Chemical composition | Replication | Standards |

| Cellulose | 3 | Kurschner-Hoffer |

| Hemicellulose | 3 | Direct extraction with aqueous alkali |

| Klason lignin | 3 | ASTM D 1106-56 |

| Alcohol-benzene solubility | 3 | ASTM D 1107-56 |

| Hot-water solubility | 3 | ASTM 1110-56 |

| Ash Content | 3 | ASTM D 1102-84 |

Sample collection and preparation

Wood discs 25 mm thick were systematically taken along tree height levels, at the bottom (10%), middle (50%), and top (90%) of tree height (Figure 2A) [11]. Thereafter, the collected disks were cut into small strips with a knife and dried. The strips were small enough to be placed in a grinding machine and chips were ground in the Wiley mill (Figure 2C). Then the milled material was placed in a shaker with sieves to pass through a number 40 mesh sieve (450 µm) yet retained on a number 60 mesh sieve (250 µm). Finally, each chemical composition analysis was carried out according to American standards for Testing Materials (ASTM).

Figure 2: Sample collection and preparation: cutting disks and coding (A&B), Grinding (C&D).

Data analysis

The statistical analysis was carried out using a statistical analysis program (SAS). Duncan’s multiple range test was used to compare mean values for each chemical component along tree height levels at α = 0.05.

The results showed that the studied species had the highest value of cellulose and Klason’s lignin in the top portion (90%) of the wood. While, the bottom portion (10%) gave a higher value of hemicellulose, alcohol-benzene, hot-water solubility, and ash content (Table 2).

Cellulose content

Cellulose content also has a direct effect on the physical and mechanical properties of a sheet of paper [12]. The Cellulose content of A. melanoxylon increased from the bottom (42.93%) to the top portion (47.03%) (Table 2). Duncan multiple range tests show that there was a significant difference between the bottom and the top portion of cellulose content, however, both portions were insignificant from the middle portion at p < 0.05 (Table 2). The increasing amount of cellulose content from bottom to top observed in this study was also reported by Amini, et al. on A. mangium [13]. The average cellulose content (45.02%) is similar to that found in other acacia species. For instance, in Acacia tortilis (46.92%), and Acacia origina (45.54%) [14].

However, lower than A.mangium (48.42%) (Amini, et al. [13], E. globules (50%), and E. Urograndis (48.6%) [15]. The result was also lower than O. abyssinica (52.06%) [16], however similar to the Pseudo stem of Ensete Ventricosum (44.3%) (Lemma, et al. of non-wood plants growing in Ethiopia [17]. The difference in cellulose content with bamboo and other woody species may be due to species, age, and growth environment differences of sample trees since they affect the chemical composition of the tree species [18]. Previously many scholars reported the relationship between cellulose content and pulp and paper properties. For instance, Kiaei, et al. reported a positive relationship between pulp quality and cellulose content [19]. Moreover, the high cellulose content provides a high pulp yield reported by Khoo and Peh [20]. According to Abdul-Khalil, et al. a cellulose content of 40 percent or higher was satisfactory for pulp and paper production [21]. Therefore, A. melanoxylon is suitable to use as a raw material for pulp and paper production.

Klason lignin content

Determination of lignin content in raw materials provides information for evaluation and application of the processes. Hardness, bleach ability, and other pulp properties, such as color, are associated with the lignin content [22]. Softwoods contain around 25% - 33% lignin and in hardwoods, it can vary between 18% - 25% [23]. Klason lignin content of A. melanoxylon wood increased from the bottom to the top portion. Duncan multiple range tests showed that Klason lignin of both the bottom and middle of tree portions significantly vary from the top portion at p < 0.05 (Table 2).

| Table 2: Mean and standard deviation of chemical composition along tree height levels. | |||

| Chemical composition (%) | Height levels (%) | ||

| Bottom (10%) | Middle (50%) | Top (90%) | |

| Cellulose | 42.93±0.40a | 45.10±2.87ab | 47.03±1.46b |

| Hemicellulose | 24.73±0.60b | 21.56±2.48ab | 19.51±1.42ab |

| Klason lignin | 23.13±0.25a | 23.31±0.10a | 24.93±0.77b |

| Alcohol-benzene | 4.06±0.79b | 3.19±0.06ab | 2.46±0.39a |

| Hot-water solubility | 5.68±0.30a | 5.45±0.05a | 5.42±0.49a |

| Ash | 0.56±0.05b | 0.52±0.025b | 0.37±0.02a |

| The mean of the same row with different superscript are significantly different (p < 0.05) | |||

The mean of Klason lignin in A. melanoxylon obtained in this study (23.79%) was higher than the report of Santos, et al. (21.10%) [24] and Lourenco, et al. (18.6%) [25] on the same species. The difference in Klason lignin may be due to age and growth environment variation since they affect wood’s chemical properties [17]. However, the result obtained was similar to other Acacia species. For instance, in A. mangium it ranges from 21.6% - 24.3%, and 21.6% - 24.6% in A. auriculiformis [26].

Pulpwood requires a low lignin content since lignin content is negatively correlated with pulp yield and fiber strength [27,28]. Lignin also causes the paper to become fragile and because of light oxidation, which results in the production of color bands, it gives the paper a dark or yellowish look [12]. According to Ververis, et al. [29], raw material with Klason lignin of less than 30% has acceptable for pulp and paper production. Therefore, A. melanoxylon Klason lignin from the study site was suitable for the production of pulp and paper.

Hemicellulose

According to Bakker and Elbersen [30], low hemicellulose content in raw material decreases the water-absorbing capacity and thus minimizes the duration of pulping activity. Duncan’s multiple range tests show that the bottom and top portions significantly varied in hemicellulose content, however, both portions are insignificant with the middle portion at p < 0.05 (Table 2). The average hemicellulose content for this study (21.93%) is similar to Acacia tortilis (21.10%) and Acacia etbaica (21.37%) [31]. However, it is less than A. mangium (35.5%) [12] and more than Ethiopia’s growing O. abyssinica (16.90%) [15]. The difference in hemicellulose content may be due to species, age, and growth environment differences of sample trees since it affects the chemical compositions of wood [17] Table 3.

| Table 3: Analysis of Variance (ANOVA) for chemical composition along tree height. | |||||||

| Source of Variation | Mean square and Statistical significance | ||||||

| df | Cellulose | Lignin | Alcohol-Benzene | Hot-Water | Hemicellulose | Ash | |

| Height | 2 | 12.621 ns | 2.944* | 1.926* | 0.0592 ns | 0.746* | 0.029* |

| Notes: ns: not significant; at p > 0.05, *significant at p < 0.05. | |||||||

Extractive content

Extractives of raw materials are undesirable parts since they can have a negative impact on pulping and bleaching operations. For example, low extractives content was related to higher pulp yields [25] and it will also cause pitch problems in the paper-making process, which resulted in processing and production stopping for a moment [31].

Hot - Water soluble extractives

Hot-water soluble extracts of wood include components such as tannins, sugars, gums, starches, coloring, polysaccharides, inorganic salts, cyclitols, and some phenolic substances [32]. The result showed that hot-water extractives of A. melanoxylon were higher at the bottom portion (5.68%) and minimum at the top portion of A. melanoxylon (Table 2). However, hot-water extractives are insignificant along tree portions at p < 0.05. The overall mean of hot-water extractives obtained in this study (5.52%) was lower than O.abyssinica (6.80%) [15] and bagasse fiber (7.42%) [33]. However, the result was similar to tropical pulpwood species: Gmelina Arborea (5.20%) and Leucaena leucocephala (5.60%) [34]. Therefore, it is suitable for pulp and paper making.

Alcohol benzene soluble extractives

No single organic solvent is capable of removing all these substances and different solvents remove only soluble components in their solubility range of polar to non-polar. The mixture, ethanol-benzene, appears to provide the most complete removal of residual solvent-extractable substances in wood.

Based on Table 2, alcohol-benzene extractives were higher at the bottom (4.06%) than both the middle and the top portions. Duncan’s multiple range tests showed that alcohol benzene extractive content significantly affected the bottom and top portions (Table 2).

The overall mean obtained in the alcohol-benzene extractive (3.24%) was similar to the previous report of Lourenço, et al. (3.96% [25] however, lower than the report of Santos, et al. [24] (6.51%) on A. melanoxylon, which they used alcohol-toluene solution instead of alcohol-benzene solution used in this study. The result was higher than A. mangium (1.77%) [12], while it is less than O. abyssinica (5.60%) [15]. High solubility will be an indicator of low pulp yield as well as higher chemical consumption both in pulping and bleaching [35,36].

Ash content

According to Table 2, the highest ash content was observed in the bottom portion (0.56%) while, the lowest value was in the top portion (0.37%) of A. melanoxylon wood. Ash content was insignificant between the bottom and middle portions although, both portions are significant to the top portions at p < 0.05 (Table 2). The overall mean percentage of ash content obtained in this study (0.48%) is similar to the previous report of Santos, et al. (0.43%) [24] on A. melanoxylon, however lower than Acacia tortilis (1.94%), Acacia origina (1.99%) [13] and E. globules (1.0%) [37]. The difference may be due to species, age, and growth environment differences of sample trees since it affects the chemical properties of the wood [17].

The result shows that the portion of wood with higher density contributed to the increase in the percentage of ash content because of the transformation of sapwood into heartwood from the bottom to the top portion of the tree. Panshin and Zeeuw reported that the bottom portion has more heartwood and higher density, consequently higher ash content compared with the top portion of the tree [38]. According to Ogunsile, et al. high ash content is undesirable for pulping as they affect normal alkali consumption and create problems in waste liquor recovery [39,40]. The average ash content percentage of A. melanoxylon obtained in this study (0.48%) was lower than other tropical pulpwood species; E. globulus (1.0%), Gmelina Arborea (0.84%) and Leucaena leucocephala (2.50%) which show the better property for pulp and paper production [36] Table 4.

| Table 4: Comparison of the Chemical Composition of Acacia melanoxylon Wood with Other Paper Making Raw Materials. | ||||||

| Chemical composition (%) | ||||||

| Species | Cellulose | KL | Hem | AB | HW | Ash |

| A. melanoxylon (*) | 45.02 | 23.79 | 21.93 | 3.24 | 5.52 | 0.48 |

| E. globules (a) | 56.90 | 17.80 | NA | 1.40 | NA | 1.0 |

| A.mangium(b) | 48.34 | 19.78 | 35.71 | 1.77 | NA | NA |

| Beech wood(c) | 45.80 | 21.90 | NA | NA | NA | 0.4 |

| Bagasse fiber(d) | 42.34 | 21.70 | NA | 1.85 | 7.42 | 2.10 |

| Cotton stalk€ | 43.80 | 17.60 | NA | NA | NA | 3.50 |

| O.abyssinica(f) | 52.06 | 22.47 | 16.90 | 5.60 | 6.80 | 5.30 |

| (*) This study (*), (a)[37], (b)[12], (c)[40], (d)[33], (e)[29], (f)[15] Notes KL: Klason Lignin; AB: Alcohol-Benzene solubility; Hem: Hemicellulose; HW: Hot-Water; NA: Not Available. |

||||||

The basic information on the chemical composition of Acacia melanoxylon as a source of fibrous raw material for pulp and paper production was examined. Cellulose, hemicellulose, Klason lignin, Alcohol-benzene solubility, Hot-water solubility, and ash content were considered. All chemical compositions were significantly varied between the bottom and the top portion except, hot-water extractives. Compared to the wood properties related to pulp and paper quality with those of Eucalyptus and Acacia species currently used for commercial pulpwood, A. melanoxylon showed better properties. Generally, A. melanoxylon wood gave a good indication of its properties which is becoming a raw material for the pulp and paper industry.

Recommendations

Based on the findings of the study, the following points were recommended: -

- Since A. melanoxylon grown in the Chencha district is suitable in terms of its chemical composition for pulp and paper making, attention should be given to tree growers, investors, government, and non-governmental organizations on its plantation expansion.

- The fiber properties of this species should be investigated in different ways of tree management and tree spacing.

- Further research should be carried out on different agroecology of Ethiopia to obtain a comprehensive understanding of the fiber properties of the species.

- Besides the information on the properties of the fibers revealed in this study, the production and testing of its pulp and paper should be done.

The authors acknowledge the Forest Products Innovation Center of Ethiopian Forest Development’’ for providing financial and laboratory facilities. Additionally, thank goes to all individual friends and staff those supported and shared their thoughts until the completion of this work.

- Sharma M, Sharma CL, Kumar YB. Evaluation of fiber characteristics in some weeds of Arunachal Pradesh, India for pulp and paper making. Research Journal of Agriculture and Forestry Sciences. 2013; 1(3):15-21.

- Hurter RW, Riccio FA. Why CEO’s Don’t Want to Hear about Non woods-or SHOULD THEY? In Proceedings, 1998 North American Non wood Fiber Symposium (Atlanta) 1998;1-10.

- Jiménez L, Rodríguez A, Ferrer JL, Pérez A,Angulo V. Paulownia, a fastgrowing plant, as a raw material for paper manufacturing. Afinidad. 2005; 62(516).

- ERCA. Ethiopian Revenue and Custom Authority. 2015; 100105.

- Midgley SJ, Turnbull JW, Pinyopusarerk K. Industrial Acacias in Asia: Small Brother or Big Competitor? In: Eucalyptus Plantations - Research, Management and Development, R-P. Wei and D. Xu (Eds). Proc. Of International symposium on “Eucalyptus Plantations", Guangzhou Zhaoqing, China, 1-6 September 2002, World Scientific, Singapore. 2003; 19-36.

- Bekele-Tesemma A. Useful Trees and Shrubs for Ethiopia: Identification, Propagation and Management for 17 Agroclimatic Zones. relma and icraf Project, Nairobi. 2007.

- Desalegn G, Abegaz M, Teketay D, Gezahgne A. Commercial timber species in Ethiopia: Characteristics and uses. A handbook for forest industries, construction sectors, foresters and other stakeholders 2012.

- CCIDI. “2015-2020 Strategic Plan" A draft document by Chemical and Construction Input Industry Development Institute, Addis Ababa, Ethiopia. 2015.

- Cao S, Ma X, Lin L, Huang F, Huang L,Chen L. Morphological and chemical characterization of Green bamboo (Dendrocalamopsis oldhami (Munro) Keng F.) for dissolving pulp production. BioResources 2014; 9(3): 4528-4539.

- Ogata A. Indigenous Common Grazing land Management in Chencha Wereda. South Ethiopia. 2006.

- Latib NA, Kasim NSMTJ. Physical and chemical properties of Kelempayan (Neolamarckia cadamba sp.) wood. International Journal of Latest Research in Science and Technology. 2014; 3(6):215-219.n

- Ghalehno M,Nazerian M. The investigation on chemical and anatomical properties of Roselle (Hibiscus sabdariffa) stem. International Journal of Agriculture and Crop Sciences. 2013; 5(15):1622.

- Amini MHM, Rasat MSM, Mohamed M, Wahab R, Hafizah N, Ramle IK Yunus AAM. Chemical Composition of Small Diameter Wild Acacia Mangium Species. 2006.

- Nasser RAS, Aref IM. Fuel Wood Characteristics of Six acacia species growing wild in the southwest of Saudi Arabia as affected by geographical location. Bioresources. 2014; 9(1):1212-1224.

- Evtuguin DV, Neto P. Recent advances in eucalyptus wood chemistry: Structural features through the prism of technological response. In 3rd International colloquium on eucalyptus pulp. Belo Horizonte, Brazil. 2007.

- Tolessa A, Woldeyes B, Feleke S. Chemical Composition of Lowland Bamboo (Oxytenanthera abyssinica) Grown around Asossa Town, Ethiopia. World Scientific News. 2017; (74):141-151.

- Lemma HB, Kiflie Z, Feleke S, Yimama A. Chemical and Morphological Analysis of Enset (Ensete Ventricosum) Fiber, Leaf, and Pseudo stem Lignocellulose .2016; 5(2): 139-151.

- Smook GA .Handbook for Pulp & Paper Technologists, Vancouver: Angus Wilde Publications. 1992.

- Kiaei M, Tajik M, Vaysi R.Chemical and biometrical properties of plum wood and its application in pulp and paper production. Maderas. Ciencia y tecnología. 2014; 16(3):313-322.

- Khoo KC, Peh TB. Proximate chemical composition of some Malaysian hardwoods. The Malaysian Forester (Malaysia). 1982.

- Khalil A, Alwani S, Omar M. Chemical composition, anatomy, lignin distribution, and cell wall structure of Malaysian plant waste fibers. Bio Resources. 2006; 1(2):220-232.

- Malik RS, Dutt D, Tyagi CH, Jindal AK. Lakharia LK. Morphological, anatomical and chemical characteristics of Leucaena leucocephala and its impact on pulp and paper making properties. 2004.

- Bowyer JL, Haygreen JG, Shmulsky R. Forest products and wood science: an introduction (5th edition). Blackwell, Ames, Iowa. 2007; 558.

- Santos A, Anjos O, Amaral ME, Gil N, Pereira H. Simões R. Influence on pulping yield and pulp properties of wood density of Acacia melanoxylon. Journal of wood science. 2012; 58(6):479-486.

- Lourenço A, Baptista I, Gominho J, Pereira H.The influence of heartwood on the pulping properties of Acacia melanoxylon wood. Journal of wood science. 2008; 54(6):464-469.

- Marsoem SN, Irawati D. Basic properties of Acacia mangium and Acacia auriculiformis as a heating fuel. In AIP Conference Proceedings. 2016; 1755: 130007).

- Amidon TE. Effect of the wood properties of hardwoods on kraft paper properties. Tappi. 1981; 64(3): 123-126.

- Dutt D, Tyagi CH. Comparison of various eucalyptus species for the morphological, chemical, pulp and paper making characteristics. 2011.

- Ververis C, Georghiou K, Christodoulakis N, Santas P, Santas R. Fiberdimensions, lignin and cellulose content of various plant materials and their suitability for paper production. Industrial Crops and Products. 2004; 19(3): 245-254. DOI:10.1016/J.INDCROP.2003.10.006

- Bakker RR, Elbersen HW October. Managing ash content and quality in herbaceous biomass: an analysis from plant to product. In 14th European Biomass Conference. 2005; 17-21.

- Allen LH. Mechanisms and control of pitch deposition in newsprint mills. Tappi.1980; 63(2):81.

- Browning BL. Methods of wood chemistry. Volumes I & II. Methods of wood chemistry. Volumes I & II. 1967.

- Agnihotri S, Dutt D, Tyagi CH. Complete characterization of bagasse of early species of Saccharum officinerum-Co 89003 for pulp and paper making. BioResources. 2010; 5(2):1197-1214.

- Onuorah EO, Nwabanne JT, Nnabuife ELC. Pulp and paper making potentials of elaeis guineensis (oil palm) grown in south east, Nigeria. World Journal of Engineering. 2015;12(1): 1-12.

- Ates S, Ni Y, Akgul M, Tozluoglu A. Characterization and evaluation of Paulownia elongota as a raw material for paper production. African Journal of Biotechnology. 2008; 7(22).

- Khristova P, Kordsachia O, Patt R, Dafaalla S. Alkaline pulping of some eucalypts from Sudan. Bioresour Technol. 2006 Mar;97(4):535-44. doi: 10.1016/j.biortech.2005.04.006. Epub 2005 Jun 2. PMID: 15935655.

- Miranda I, Gominho J, Pereira H. Incorporation of bark and tops in Eucalyptus globulus wood pulping. Bioresources. 2012; 7(3):4350-4361.

- Panshin AJ, Zeeuw CD. Textbook of wood technology. McGraw-Hill BookCo. 1980.

- Ogunsile BO, Uwajeh CF. Evaluation of the pulp and paper potentials of a Nigerian-grown Bambusa vulgaris. World Applied Sciences Journal. 2009; 6(4), 536-541.

- Demirbas A. Aqueous glycerol delignification of wood chips and ground wood. Bioresource Technology. 1998; 63(2):179-185.