More Information

Submitted: September 06, 2022 | Approved: September 19, 2022 | Published: September 20, 2022

How to cite this article: Abara L, Bekele T. Evaluation of fiber characteristics and basic density of Acacia melanoxylon (R.Br.) grown in Ethiopia for pulp and paper making. Ann Civil Environ Eng. 2022; 6: 053-061.

DOI: 10.29328/journal.acee.1001041

Copyright License: © 2022 Abara L, et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Keywords: Basic density; Fiber dimension; Derived fiber values; Paper production

Evaluation of fiber characteristics and basic density of Acacia melanoxylon (R.Br.) grown in Ethiopia for pulp and paper making

Lamesa Abara1* and Tsegaye Bekele2

1Ethiopian Forest Development, Forest Products Innovation Center (FPIC) Addis Ababa, Ethiopia

2Professor and lecturer at Hawassa University, Wondogenet College of Forestry and Natural Resources, Hawassa, Ethiopia

*Address for Correspondence: Lamesa Abara, Ethiopian Forest Development, Forest Products Innovation Center (FPIC) Addis Ababa, Ethiopia. Email: [email protected]

The fiber characteristics and basic density of Acacia melanoxylon were investigated for its potential as a raw material for pulp and paper production. Six trees from the even-aged stand and similar diameter class were selected randomly from the Chencha district of Ethiopia. Wood disks were systematically cross-cut from a log along tree height levels, at the bottom (10%), middle (50%) and top (90%) of the merchantable height and blocks of wood (2 cm x 2 cm x 2 cm) were taken from pith to periphery at near pith (10%), middle (50%) and near bark (90%) of disk radius. Fiber maceration and basic density were determined, by 50% nitric acid solution and water displacement method respectively. All the data were analyzed using a two-way analysis of variance at α = 0.05. The fiber characteristics of the selected trees; the fiber length, fiber diameter, lumen diameter and cell wall thickness were measured while the-slenderness ratio, Runkel ratio, flexibility coefficient and wall coverage ratio of the fibers were derived from the measured fiber dimensions. The result showed that- the overall mean were, 1.04 mm, 21.60 µm, 15.36 µm, 3.75 µm, 0.48, 48.05%, 71.10%, 0.34 and 0.56 g/ml, for fiber length, fiber width, lumen diameter, cell wall thickness, Runkle ratio, slenderness ratio, flexibility ratio, wall coverage ratio and basic density, respectively. Generally, Acacia melanoxylon wood is suitable for pulp-and-paper-production, to due-to-its adequate-fiber dimension, derived fiber value and basic density. Therefore, attention should be given to tree growers, government and non-governmental organizations on the plantation expansion of Acacia melanoxylon.

Global paper consumption is expected to increase to 500 million tons by 2025, which is about 1.6% growth a year [1,2]. The consumption of paper-and paperboard products increases continuously due to numerous reasons, which include population growth and industrialization in developing countries [3]. This ever-increasing demand for paper forces countries of the world to find technically and economically viable fiber sources to supplement forest-based resources for pulp and paper production [4].

Pulp is produced from hardwood, softwood and agro-residues. Hardwood and softwood pulping account for 95% of the total worldwide pulp production and the rest 5% comes from non-wood raw materials, mainly agro-residues and grasses [5]. The demand for paper and paperboard products in Ethiopia has grown fast with endless development. For instance, according to ERCA [6], the demand is growing by 10% every and in 2003 average annual domestic production of paper was 7,266 tons while in the same year 127,132 tons of paper have been imported which means the average total supply of paper during the period under consideration was 134,398 tons per annum, of which only about 5% was locally produced.

Hence, the consideration of some fast-growing wood species in the Ethiopia forest as a potential fiber source for pulp production is the right step toward meeting the demand for pulp and paper. However, before recommending any wood species for pulp and paper production, adequate information on fiber characteristics and chemical composition is important, since they affect the quality of pulp and pulp products [7].

Fiber characteristics have been considered to be the most important factor for determining the degree of efficiency of wood species in pulping [8]. The strength property of paper depends on the characteristics of its fiber. It is frequently correlated with the physical and mechanical properties of paper and paperboard [9]. Morphological characteristics of the fiber, such as fiber length and width, are important parameters in estimating the qualities of pulp [10].

Basic density influences the end-use properties of the solid wood and those of the corresponding fiber products, such as pulp yield and paper quality [11]. It is also an indicator of energy consumption during pulping [12].

There are many indigenous and exotic woody species grown in Ethiopia which could be considered for their suitability as raw material for pulp and paper production. The usage of species as raw material for pulp, paper and cellulose-based industries is minimized every day and the wood imports exhaust the country’s foreign currency [13,14]. In Ethiopia, only very few plant species have been studied as raw materials for pulp and paper products such as Yushinia Alpina [15].

Acacia melanoxylon is one of the several Australian acacia species introduced to Ethiopia. This species has been distributed widely in cooler and wetter upland areas, Moist and Wet Kolla Weyna Dega and Dega agroclimatic zones and used mainly for firewood, charcoal, timber (light construction, plywood, flooring, fence posts, shade, ornamental, windbreak, gum and tannery). It is a very fast-growing tree species to a height of 35 m and produces hard and valuable timber [16]. This species reproduces mainly by seed, which is known to germinate prolifically after the fire. It also sprouts profusely from root suckers, particularly when the roots are damaged and readily coppices from damaged stems.

Even though the wide range of use of this species, is fast-growing, its ability to coppice and its adaptation to different parts of Ethiopia, its quality for pulp and paper products were not known. Therefore, this study aimed to investigate the fiber characteristics and basic density of A. melanoxylon as a potential raw material for pulp and paper production.

Description of the study area

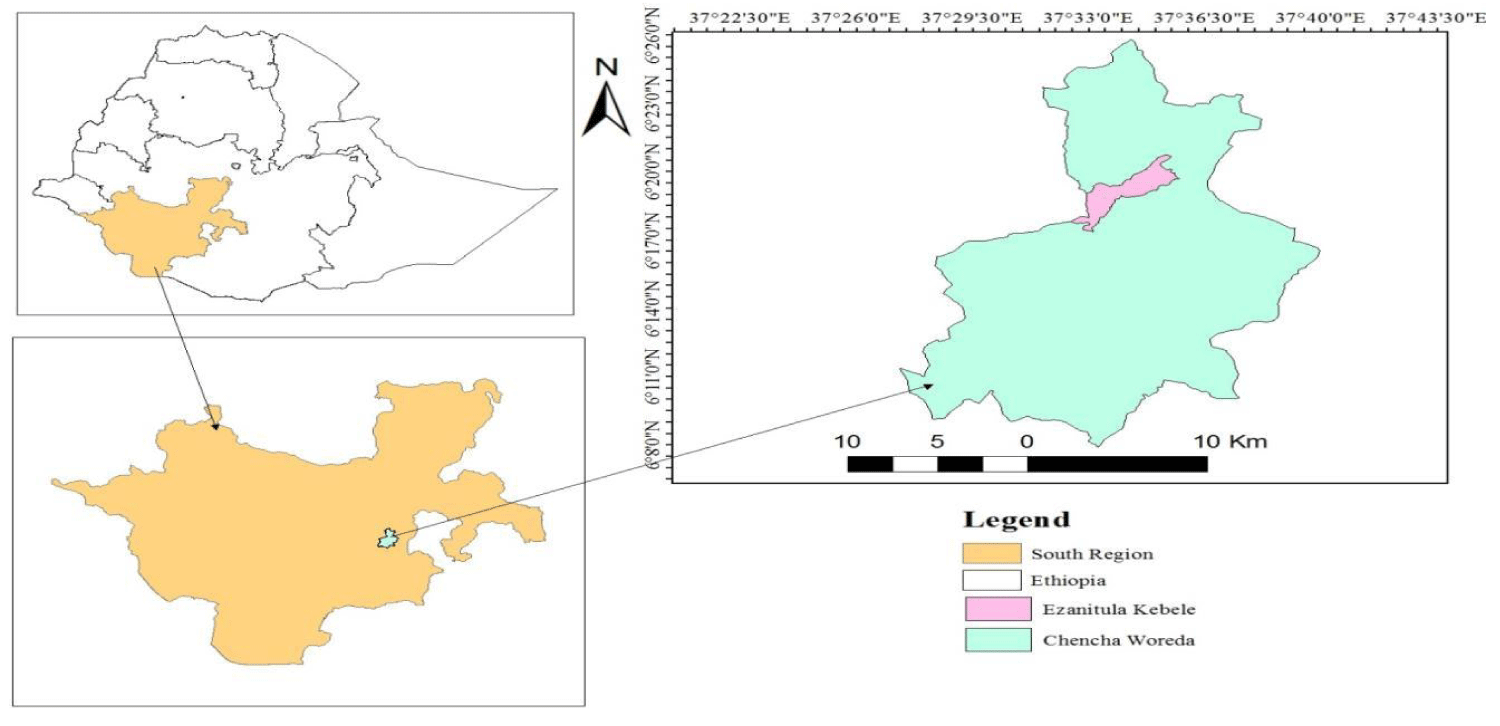

The study sample trees were taken from Chencha Woreda, SNNP region, which is located 37 kilometers North of Arbaminch and 500 kilometers from the capital city of Addis Ababa [17]. It is located 37o 26’0” - 37o 40’0” E and 6o 8’0”- 6o 26’0” N longitude and latitude respectively. The annual rainfall distribution of the area varies between 900 mm to 1200 mm (Figure 1).

Figure 1: Map of the sample collection area.

Sample collection and preparation

For investigation of fiber characteristics and basic density, wood disks were systematically cross-cut from a log along tree height levels, at the bottom (10%), middle (50%) and top (90%) of the merchantable height [18], and from each disk sample were taken from pith to periphery at near pith (10%), middle (50%) and near bark (90%) of the disk radius to perceive variations in fiber characteristics and basic density from pith to periphery.

For fiber dimension, matchstick size (1 cm × 0.2 cm × 0.2 cm) was taken and 50% nitric acid was used for maceration processes since it consumes less time and economical method [19]. Matchstick-size samples were taken in test tubes, immersed completely in nitric acid solution, and kept in a water bath at 70 ºC for 5 to 6 hrs to get separated white colored. After cooling, nitric acid was drained and macerated fibers were washed with distilled water and filtered using Whatman Grade 1 filter paper for separation of fibers [19]. Two slides were prepared per sample and images were taken by using a camera-attached Motic BA210 microscope. Then the dimensions of 50 fibers were measured [20] using the Motic software.

For cell measurement, the specimen was softened in warm water below 100 ºC for one hour and slices were cut by using a Leica sliding microtome with a thickness of 20 µm [20]. Then the slice was immersed in safranin solution and 25%, 50% and 75% of alcohol concentrations respectively for one minute to remove excess safranin solution that may cause invisibility of cells [21]. Finally, the specimens/slice were immersed in xylene for 1 minute and put on the slide (standard 7.5 cm × 2.5 cm). The small amount of Canada balsam was dropped and covered using a slide cover and kept to dry.

Then an image was taken with a camera-attached Motic BA210 microscope and 30 cells from each distance from pith lumen diameters and cell wall thickness were measured from each distance from the pith [20], by using the Motic software. The equations used for the computation of the derived values: Runkel ratio [22], slenderness ratio [23], flexibility coefficient [24] and wall coverage ratio [25], are expressed as equations 1 to 4.

(1)

(2)

(3)

(4)

For basic density the specimens of wood were cut at three distances from the pith (10%, 50% and 90% of the radius length) [26] by the dimension of 20 mm x 20 mm x 20 mm according to ASTM D14394 [27], to perceive variations in basic density from pith to periphery from each disk. The volume of each specimen was determined by immersing the sample in water containing a beaker and water displaced from the beaker (in milliliter) by the submerged sample was recorded. Then each specimen was dried in an oven drying machine at a temperature of 105 ºC for 24 hrs and re-weighed until a constant weight was obtained. The oven dry weight of each sample was measured and recorded. Finally, basic density was calculated by dividing the oven-dry weight of the sample (gm) by the volume of displaced water at green (ml).

Statistical analysis

Statistical analysis was conducted using the SPSS program in conjunction with analysis of variance (ANOVA). Duncan’s multiple range test (DMRT) was used to compare mean values for each fiber dimension and basic density along height levels and from the pith to the periphery at α = 0.05.

Fiber characteristics

Variation of fiber length along tree height and from pith to periphery: Fiber length is an important fiber dimension that affects pulp quality and paper strength [28]. Wimmer, et al. [11], also reported that the fiber length of E. globulus had a strong effect on pulp yield and freeness, as well as active alkali consumption, in addition, to tear index and bending stiffness.

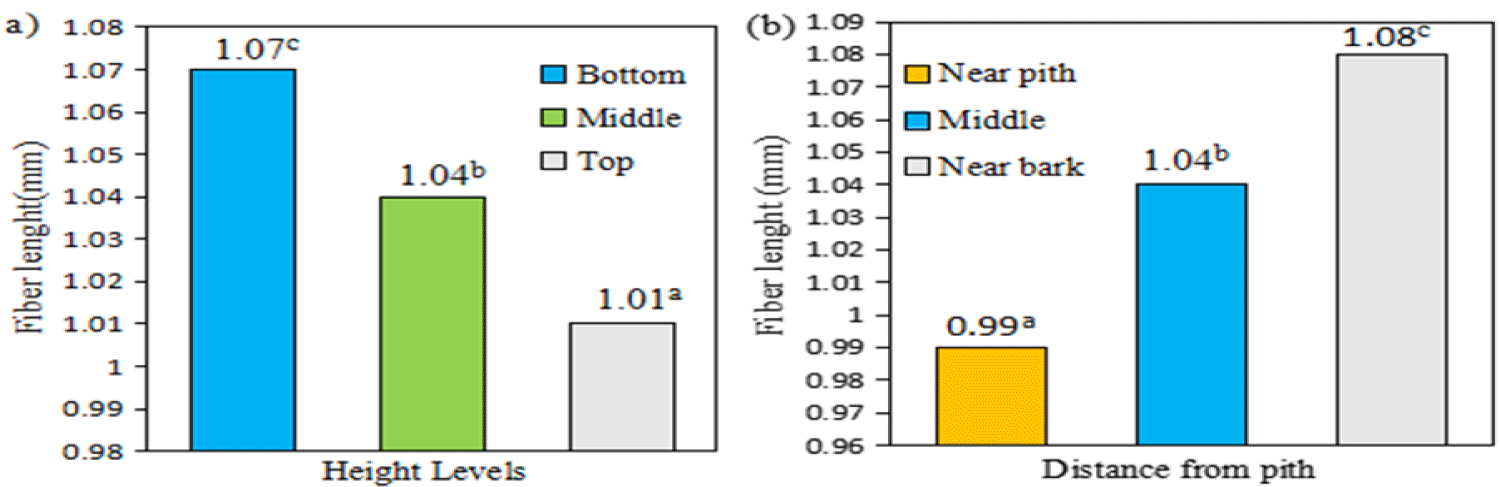

This study showed that fiber length ranged from 1.01 mm to 1.07 mm along tree height and 0.99 mm to 1.08 mm from pith to periphery of the disks. It varied significantly along tree height levels (Figure 2a) and from the pith to the periphery (Figure 2b) at p < 0.05. Fiber length decreases from bottom to top portions however, it increases from pith to periphery. The general decrease in fiber length from the bottom to the top and its corresponding increase from near pith to periphery observed in this study had earlier been reported by Tavares, et al. [29], on A. melanoxylon wood. The decreasing trend of fiber length from bottom to top observed in this study could be due to the fact that minimal net photosynthetic for cell development at the top caused by competition for leaf and branch development leads to better cell production at the bottom [30]. The increase of fiber length from pith to periphery could be explained based on the increase in the length of cambial initials with increasing cambial age and crown formation [31]. Furthermore, due to many molecular and physiological changes that normally occur in the vascular cambium during the aging process [32]. The cells produced in the primary xylem divide less frequently, thus allowing more time for the fusiform initial section to elongate longitudinally and transversely [33].

Figure 2: Variation of fiber length along tree height levels (a), distance from the pith (b); Mean with different letter are significant (p < 0.05).

The mean value in fiber length obtained in this study (1.04 mm) is close to previously reported by Tavares, et al. [29], which ranges from 0.91 mm to 0.97 mm, along with tree height levels and 0.75 mm to 1.06 mm from pith to the periphery of A. melanoxylon. But, the result was higher than the report of Santos, et al. [34], which ranges from 0.63 mm to 0.66 mm on the same species. This difference may be due to the age variation of sample trees since fiber length increase with the age of the tree [31].

The result is also similar to pulpwood species: Gmelina Arborea (1.03 mm), Leucaena leucocephala (1.01 mm) [35] and Eucalyptus species (0.67 mm - 1.06 mm) [36,37]. Moreover, the results were in line with other acacia species, namely; Acacia mangium which ranges from 0.96 mm to 1.20 mm [38] and Acacia bilimekii (1.016 mm - 1.201 mm) [39]. Since the result obtained in fiber length is similar to other pulpwood, the studied species is suitable for pulp and paper making.

Fiber width, lumen diameter and cell wall thickness

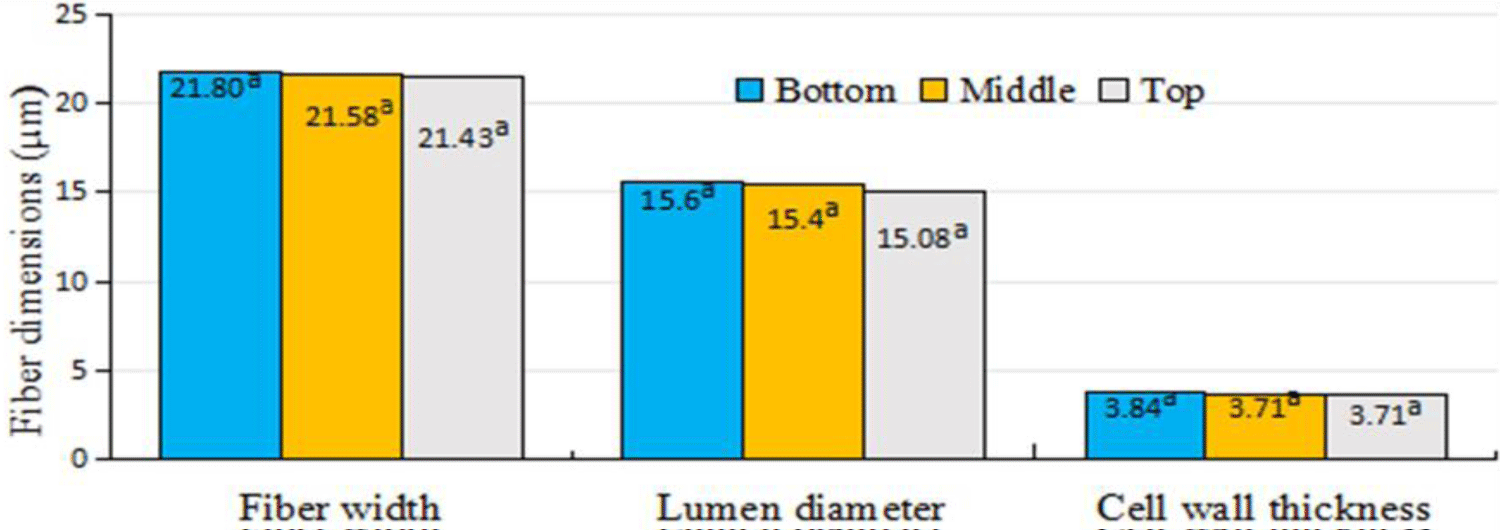

Variation along tree height levels: The result obtained in fiber width, lumen diameter, and cell wall thickness along tree height of A. melanoxylon were presented in Figure 2. Along with tree height, fiber width ranges from 21.43 µm to 21.8 µm. Duncan, multiple range tests showed that fiber width was insignificant along height levels at p < 0.05 (Figure 3) and it decreases from the bottom to the top of a tree. The mean fiber width obtained in this study (21.60 µm) was higher than previously reported by Santos, et al. [40], (19.55 µm) and Santos, et al. [34] (17.6 µm) on the same species. This difference may be due to the geographical location and age of the sample trees. The result is also higher than pulpwood species such as E. globulus. Accordingly, Santos, et al. [41], observed values ranging from 18.3 µm to 19.3 µm, on A. melanoxylon and Miranda, et al. [42], reported 14.5 µm to 22.2 µm, of fiber width.

Figure 3: Variation of fiber characteristics along tree height levels. The mean of the same fiber dimension with the different letters is significantly different (p < 0.05).

The decreasing trend of fiber width from base to top observed in this study could be due to the fact that minimal net photosynthetic for cell development at the top caused by competition for leaf and branch development leads to better cell production at the base [30].

The lumen diameter of A. melanoxylon ranges from 15.08 µm to 15.6µm along the height levels. Duncan’s multiple range test showed lumen diameter was insignificant along tree height levels at p < 0.05 (Figure 3). It decreases from bottom to top of tree portions. Lumen diameter affects the pulping process. For instance, a larger lumen diameter gives better pulp beating because of the penetration of liquid into empty spaces of the fibers [43].

The cell wall thickness ranges from 3.71 µm to 3.84 µm along the tree height of A. melanoxylon. Analysis of variance carried out at a 5% probability level showed that cell wall thickness was insignificant difference along tree height at p < 0.05 (Figure 3). It decreases from bottom to top of tree portions. The result obtained was lower than other pulpwood. For instance, in E. globulus it ranges from 5.4 μm to 7.3 μm along height levels with decreasing trend from the bottom to the top of the tree [44].

Wood with thick cell walls tends to produce paper with a poor printing surface and poor burst strength. Thick-walled cells do not bend easily and do not collapse upon pulping, which inhibits chemical bonding. However, thin-walled cells collapse upon pulping, bond well together chemically and produce a smoother paper surface [45]. Therefore, A. melanoxylon has better than E. globulus for pulping in terms of its cell wall thickness.

Variation across from pith to periphery

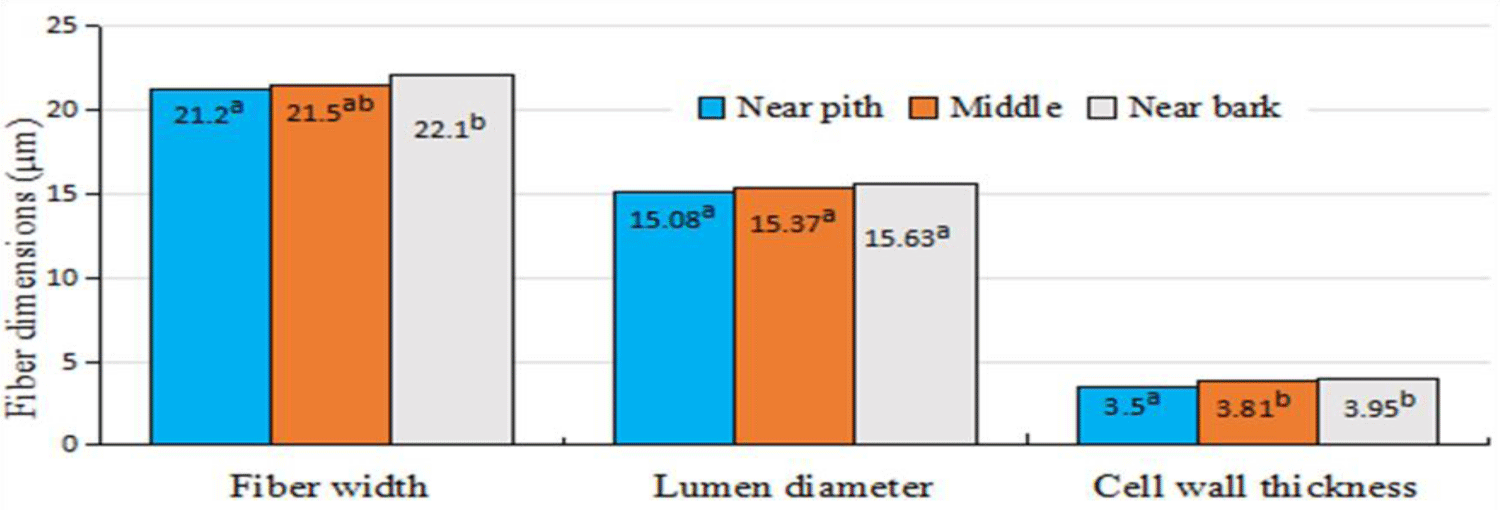

The fiber dimensions of A. melanoxylon wood at different distances from pith to bark are presented in Figure 4. Across the distance from the pith, fiber width ranges from 21.2 µm to 22.1 µm. Duncan multiple range tests showed that fiber width was significant between the near pith and at the periphery, although both sections were insignificant varied with the middle section of a disk at p < 0.05 (Figure 4). Across the distance from the pith, fiber width increased from the pith to periphery. A similar trend was reported by Izekor and Fuwape [46], on Teak and Ogunsanwo [8], on T. scleroxylon. The reason for this trend was attributed to the influence of cambium age on the development and maturation of fiber from pith to bark [30].

From the pith to the periphery of A. melanoxylon, the mean lumen diameter ranges from 15.08 µm to 15.63 µm (Figure 4).

Analysis of variance carried out at a 5% probability level showed that lumen diameter was insignificant difference where it increases from pith to periphery (Figure 4). The increase in lumen diameter from pith to the periphery is attributed to increase in cell size and active physiological development of the wood as the tree grows in girth [30].

The cell wall thickness ranges from 3.5 µm to 3.95 µm across from the pith to the periphery of the disk of A. melanoxylon wood. Analysis of variance carried out at a 5% probability level showed cell wall thickness was insignificant variation between middle and at near bark, however, both the inner section of the disk showed a significant difference to near pith at p < 0.05 (Figure 4). Cell wall thickness increase from near pith to the periphery of the disk. The increase of cell wall thickness from pith to periphery was also previously reported by Tavares, et al. [29], on A. melanoxylon wood.

Figure 4: Variation of fiber characteristics across the distance from pith. The mean of the same fiber dimension with different superscripts is significantly different (p < 0.05).

The result obtained in cell wall thickness was similar to Tavares, et al. [29], which ranges from 3.45 μm to 3.89 μm. It is also similar to Eucalyptus species (3.29 μm - 3.86 μm) [36].

However greater than Jorge [47], which ranges from 1.8 μm to 2.5 μm, and higher than Santos, et al. [24], which has 2.00 μm and 2.40 μm in earlywood and latewood respectively, on A. melanoxylon. The result was less than A. cochliacantha which increases 5 μm to 7 μm from pith to bark [39]. This difference may be due to different species, ages and growing environments of sample trees since it affects wood fiber properties [48] (Table 1).

| Table 1: Summary of analysis of variance for fiber characteristic | |||||

| Source of variation | Mean square and statistical significance | ||||

| DF | FL | FW | LD | CWT | |

| Height | 2 | 0.018* | 0.611 ns | 1.267 ns | 0.096 ns |

| Section | 2 | 0.033* | 3.773 ns | 1.340 ns | 0.955* |

| Height x Section | 4 | 0.000 ns | 0.395 ns | 0.550 ns | 0.041 ns |

| Note: FL: Fiber Length; FW: Fiber Width; LD: Lumen Diameter; CWT: Cell Wall Thickness; ns: not significant at p > 0.05, *significant at p < 0.05. | |||||

Derived fiber values

Derived fiber values along tree height: Derived values from the fiber dimensions are important to determine the suitability of the material for paper production. Based on Table 2 the mean values of the Runkle ration ranged from 0.48 to 0.49. Duncan’s multiple range tests showed that there is no statistically significant difference in Runkle ratio along tree height levels at p < 0.05 (Table 2).

The mean values of the slenderness ratio obtained along tree height levels range from 47.13% to 49.08% (Table 2).

| Table 2: Mean and standard deviation of derived fiber values along the height. | ||||

| Derived fiber values | N | Sampling height (%) | ||

| Bottom (10%) | Middle (50%) | Top (90%) | ||

| Runkle ratio | 18 | 0.49 ± 0.05a | 0.48 ± 0.05a | 0.49 ± 0.04a |

| Slenderness ratio | 18 | 49.08 ± 3.12a | 48.19 ± 3.76a | 47.13 ± 3.27a |

| Flexibility coefficient | 18 | 71.56 ± 4.66a | 71.36 ± 4.15a | 70.36 ± 4.41a |

| Wall coverage ratio | 18 | 0.35 ± 0.03a | 0.34 ± 0.04a | 0.34 ± 0.03a |

| The mean of the same row with different superscript are significantly different (p < 0.05). | ||||

It has higher in the bottom and minimum at the top portion. Duncan’s multiple range test showed that there is no significant variation in slenderness ratio between portions at p < 0.05 (Table 2). The slenderness ratio is related to fiber length and width and influences paper sheet density and increases tearing resistance [49].

The mean values flexibility coefficient along tree height levels of A. melanoxylon ranges from 70.36% to 71.56% and it decreases from the bottom to the top of the tree portion. Analysis of variance carried out at a 5% probability level show that, there is no significant difference in flexibility coefficient along tree height (Table 2).

The mean values obtained in the wall coverage ratio along tree height range from 0.34 to 0.35 and it decreases from the bottom to top portion of the tree. Duncan multiple range tests show that there is no significant difference in wall coverage ratio between portions at p < 0.05 (Table 2). The wall coverage ratio is an index for bending resistance [25] and is related to fiber flexibility [50].

Derived fiber values from pith to periphery: From the pith to the periphery of the disk the mean values of the Runkle ration range from 0.46 to 0.50. Analysis of variance carried out at a 5% probability level showed that the Runkle ratio was significantly varied between the near pith and at near bark, however, both the inner sections were insignificant variation to the middle at p < 0.05 (Table 3).

| Table 3: Mean and standard deviation of derived fiber values across the distance from the pith. | ||||

| Derived fiber values | N | Distance from the pith (%) | ||

| Near pith (10%) | Middle (50%) | Near bark (90%) | ||

| Runkle ratio | 18 | 0.46 ± 0.04a | 0.49 ± 0.06ab | 0.50 ± 0.04b |

| Slenderness ratio | 18 | 46.69 ± 3.79a | 48.37 ± 2.95a | 48.86 ± 3.44a |

| Flexibility coefficient | 18 | 71.13 ± 4.76a | 71.48 ± 4.08a | 70.72 ± 4.43a |

| Wall coverage ratio | 18 | 0.33 ± 0.02a | 0.35 ± 0.04b | 0.35 ± 0.02b |

| The mean of the same row with different superscript are significantly different (p < 0.05). | ||||

This value agrees with those previously reported by Santos, et al. [40], Anjos, et al. [51] and Santos, et al. [24] on A. melanoxylon. Furthermore, the potential of E. globulus wood for pulp and paper is well known and its Runkle value was 0.56 as reported by Patt, et al. [52]. According to Kiaei, et al. [53], the Runkel ratio is a parameter used to determine the suitability of raw material for pulp. Ona, et al. [54] reported that the Runkel ratio is significantly related to pulp yield (positively) and digestibility (negatively). Santos, et al. [24] previously reported that, if the Runkle ratio < 1, the fiber is highly appropriate for pulp and paper production, from 1 to 2 is regular and above 2 it may not be used for paper. All Runkle ratio values obtained in this study along tree height and distance from pith were lower than 1 (Tables 2,3), suggesting good potential for pulp and paper production.

Based on Table 3 the mean values obtained in slenderness ratio from pith to periphery range from 46.69% to 48.86% and it increases from inner to outer wood. Duncan’s multiple range test shows that there is no statistical significance variation in slenderness ratio from the pith to the periphery at p < 0.05. Ververis, et al. [37], reported that fiber with less than a 70 slenderness ratio is not appropriate to use as raw material in the pulp and paper industry. Hence, in terms of its slenderness ratio, A. melanoxylon is not suitable for pulp and paper production since the value obtained is less than the accepted standard (70%) both along tree height and from the pith to the periphery of the disk. According to Ogunjobi, et al. [55], pulp tear resistance increases with increasing fiber slenderness. This means paper made from A. melanoxylon would have low tear strength and therefore may not be suitable for wrapping and packaging purposes.

The value obtained in the flexibility index ranged from 70.72% to 71.48% across from the pith to the periphery and it was higher in the middle section of the disk (Table 3). Duncan’s multiple range test showed that there was no significant difference in flexibility coefficient from the near pith to the periphery of the disk at p < 0.05 (Table 3). The overall mean value obtained in flexibility coefficient was similar to previous work of Santos, et al. [24] on A. melanoxylon wood, which is in the range of elastic fiber (50% - 75%). Additionally, the value is similar to other known pulpwood. For instance, E. globulus species (72%) and E. camaldulensis (70%) [54]. According to Hemmasi, et al. [56], the flexibility coefficient (FC) can be divided into four classes: high elastic fibers with FC over 75; elastic fibers with FC between 50 and 75; rigid fibers with FC between 30 and 50; highly rigid fibers with FC less than 30. Furthermore, the values of the flexibility index ranging from 50% to 75% will produce good paper with high strength properties [57]. According to this classification, the flexibility coefficient of A. melanoxylon fibers is 71.10, so it is included in the elastic fibers group and satisfies the requirement for its suitability for pulp and paper production.

The mean values obtained in the wall coverage ratio from the pith to the periphery of A. melanoxylon range from 0.33 to 0.35 and it is higher at the periphery of the disk. Duncan’s multiple range test shows that there is no significant difference between middle and near bark, while both sections were significant to a near pith at p < 0.05 (Table 3). According to Nisgoski, et al. [58], a material with a wall coverage ratio value less than 0.4 is considered to be good pulpwood since it is not too rigid. Therefore, A. melanoxylon is suitable for pulp and paper production, since the value obtained fulfilled the accepted standard Table 4.

| Table 4: Summary of analysis of variance for derived fiber properties. | |||||

| Source of variation | Mean square and statistical significance | ||||

| DF | RR | SR | FC | WCR | |

| Height | 2 | 0.000 ns | 20.649 ns | 7.271 ns | 0.000 ns |

| Section | 2 | 0.009 ns | 17.594 ns | 2.582 ns | 0.004 ns |

| Height x Section | 4 | 0.001 ns | 4.737 ns | 18.896 ns | 0.000 ns |

| Notes: RR: Runkle Ratio; SR: Slenderness Ratio; FC: Flexibility Coefficient; WCR: Wall Coverage Ratio; ns: not significant at p > 0.05, *significant at p < 0.05. | |||||

Basic density

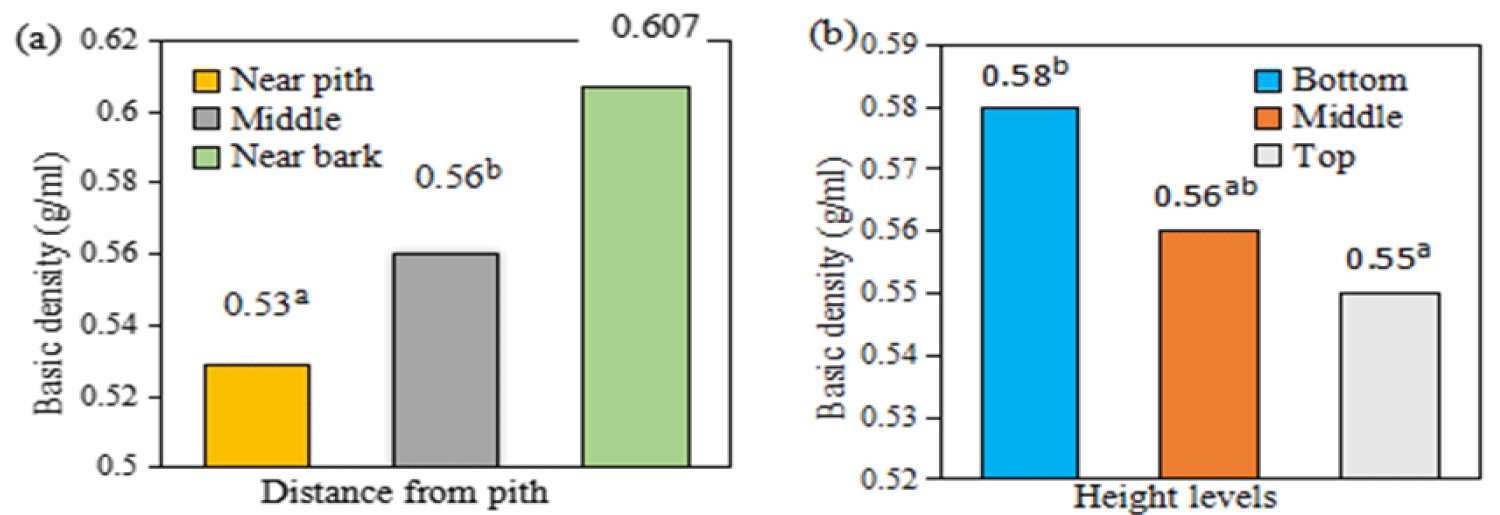

Basic density is an important parameter in pulping properties: Wood with a low basic density produces paper with high sheet density; tensile, bursting, and folding strengths; and lower resistance to beating; but with low pulp yield and tearing strength [40,59]. The overall mean basic density observed in this study was 0.56 g/ml which ranges from 0.53 to 0.607 g/ml. Basic density significantly varied between the bottom and the top portion, while both portions were insignificant to the middle portion along tree height levels at p < 0.05 (Figure 5b). From pith to periphery of the disk, basic density was significantly varied at p < 0.05 (Figure 5a).

Figure 5: Variation of basic density distance from the pith (a) and along height levels (b).

It decreases from bottom to top and increase from pith to periphery in A. melanoxylon wood.

The continuous reduction in basic density with height in the tree from bottom to the top and its corresponding increase from near pith to periphery observed in this study had earlier been reported in the wood of A. melanoxylon [26,60] and E. globulus [61]. Additionally, its significant variation from pith to periphery was also previously reported by Machado, et al. [26].

The mean basic density obtained in this study was similar to the values of the previous study on A. melanoxylon. Accordingly, Nicholas and Brown [60] report between 0.465 to 0.670 g/cm3 for 70 years-old trees; a range from 0.432 to 0.649 g/cm3 for 40-years-old with significant variation at different height levels [40] and Ilic [62], reported from 0.546 to 0.566 g/cm3 on the same species. The result obtained in this study also compared with the density of other woody species growing in Ethiopia. For instance, the value is similar to Hagenia abyssinica (0.56 g/cm3), Pouteria adolfi-friederici (0.60 g/cm3) and Juniperus procera (0.54 g/cm3). However, it is higher than the density of Cupressus lusitanica (0.430 g/cm3), Pinus patula (0.450 g/cm3) and lower than those of E. globulus (0.780 g/cm3) and E. camaldulensis (0.853 g/cm3) [13,63].

The result is also compared to other acacia species: For instance, the value is similar to A. auriculiformis (0.57 g/cm3) [64].

However, the value is higher than A. mangium wood with 0.42 and 0.45 g/cm3 for 5 and 7-years old trees respectively [65]. This higher value may be due to age and species differences since it affects the density.

The highest values of basic density at the stem base (old) and lower at the top (young), obtained in this study, may come from a combined effect of cambial age and influence from the root system [26]. Basic density influences pulp yield and paper quality [11]. According to Clark and Hicks [66], the preferred range for wood density in pulp and paper production is between 0.4 g/cm3 to 0.6 g/cm3. Therefore, the wood density of A. melanoxylon was suitable for pulp and production.

The fiber characteristics and basic density were investigated from the wood of Acacia melanoxylon trees growing in the Chencha district of Ethiopia to determine the usefulness of these trees as fiber resources for pulpwood production. Compared to the wood properties related to pulp and paper quality with those of Acacia and Eucalyptus species currently used for commercial pulpwood, A. melanoxylon showed better properties.

All fiber dimension decrease from bottom to top portion however, it increases from pith to periphery of disks and insignificantly varied along the tree height levels, except the fiber length which is highly significant at p < 0.05. Derived fiber values decrease from bottom to top portions and increase from pith to periphery. Since there was no significant variation in all the derived fiber values between tree heights, any part of the tree portion may be utilized for pulp and paper production. Basic density decreases from the bottom to the top and significantly varies between the bottom and top portions. However, it decreases from pith to periphery and is highly significant at p < 0.05. Generally, A. melanoxylon wood gave a good indication of its properties which is becoming a raw material for the pulp and paper industry due to adequate fiber dimensions, basic density, and its derived fiber values, except slenderness ratio which is lower than the accepted standard.

Based on the findings of the study, the following points were recommended: -

- Since A. melanoxylon is suitable for pulp and paper production, attention should be given to tree growers, investors, government, and non-governmental organizations on its plantation expansion.

- Further research should be carried out on different agro-ecology of Ethiopia to obtain a comprehensive understanding of the fiber properties of the species

- Fiber properties of this species should be investigated in different ways of tree management and tree spacing.

- Besides the information on the properties of the fibers revealed in this study, the production and testing of its pulp and paper should be done.

- Since there is not enough research in Ethiopia, government, research institutes and non-governmental organizations should give special attention to the evaluation of different raw materials for pulp and paper production.

The author acknowledges “The Ethiopian Environment and Forest Research Institute’’ for providing financial and laboratory facilities for this work. Additionally, thank goes to all individual friends and staff those supported and shared their thoughts until the completion of this work.

- Forest industries 2013. Global Paper Consumption is growing. Paper production and consumption growing in Asia. Retrieved 11th September. 2015.

- FAO Survey of World Pulp and Paper Capacities 2013-2018. FAO Forestry Department Rome, Italy. 2014.

- Hurter RW, Riccio FA. Why CEO’s Don’t Want to Hear about Non woods-or SHOULD THEY? In Proceedings, 1998 North American Non wood Fiber Symposium 1998; 1-10.

- Jahan MS, Sabina R, Rubaiyat A. Alkaline pulping and bleaching of Acacia auriculiformis grown in Bangladesh. Turkish Journal of Agriculture and Forestry. 2008; 32(4): 339-347.

- Jiménez L, Rodríguez A, Ferrer JL, Pérez A, Angulo V.Paulownia, a fast-growing plant, as a raw material for paper manufacturing. Afinidad. 2005; 62(516):100-105.

- ERCA Ethiopian Revenue and Custom Authority. 2015.

- Cao S, Ma X, Lin L, Huang F, Huang L, Chen L. Morphological and chemical characterization of Green bamboo (Dendrocalamopsis oldhami (Munro) Keng F.) for dissolving pulp production. BioResources. 2014; 9(3), 4528-4539.

- Ogunsanwo OY. Characterization of wood properties of plantation grown Obeche Triplochiton scleroxylon in Omo Forest Reserve, Ogun State. Ph.D. thesis. Dept. of Forest Resources Management, University of Ibadan. 2000; 253.

- Keays JL, Hatton JV, Bailey GR, Neilson RW. Present and future uses of Canadian poplars in fibre and wood products. 1974.

- Marques G, Rencoret J, Gutiérrez Suarez A, Río Andrade JCD. Evaluation of the chemical composition of different non-woody plant fibers used for pulp and paper manufacturing. 2010.

- Wimmer R, Downes GM, Evans R, Rasmussen G, French J. Direct effects of wood characteristics on pulp and handsheet properties of Eucalyptus globulus. Holzforschung. 2002; 56(3):244-252.

- Li B, Li H, Zha Q, Bandekar R, Alsaggaf A, Ni Y. Effects of wood quality and refining process on TMP pulp and paper quality. BioResources. 2011; 6(3):3569-3584.

- Desalegn G, Abegaz M, Teketay D, Alemu Gezahgne. Commercial timber species in Ethiopia: Characteristics and uses. A handbook for forest industries, construction sectors, foresters and other stakeholders. 2012.

- CCIDI 2015-2020 Strategic Plan A draft document by Chemical and Construction Input Industry Development Institute. Addis Ababa. Ethiopia. 2015.

- Tolessa A, Woldeyes B, Feleke S. Chemical Composition of Lowland Bamboo (Oxytenanthera abyssinica) Grown around Asossa Town, Ethiopia. World Scientific News. 2017; (74):141-151.

- Bekele-Tesemma A. Useful Trees and Shrubs for Ethiopia: Identification, Propagation and Management for 17 Agroclimatic Zones. relma and icraf Project, Nairobi. 2007.

- Ogata A. Indigenous Common Grazing land Management in Chencha Wereda. South Ethiopia. 2006.

- Latib NA, Kasim NSMTJ. Physical and chemical properties of Kelempayan Neolamarckia cadamba wood. International Journal of Latest Research in Science and Technology. 2014; 3(6):215-219.

- Mahesh S, Kumar P, Ansari SA, A rapid .economical method for the maceration of wood fibers in Boswellia serrata Roxb. Tropical Plant Research. 2015; 2(2): 108-111.

- Ishiguri F, Aiso H, Hirano M, Yahya R, Wahyudi I, Ohshima J, Iizuka K, Yokota S. Effects of radial growth rate on anatomical characteristics and wood properties of 10-year-old Dysoxylum mollissimum trees planted in Bengkulu. Indonesia. Tropics. 2016; 25(1):23-31.

- Zebene Kiflie HBL, Feleke S, Yimama A. Chemical and Morphological Analysis of Enset Ensete Ventricosum Fiber, Leaf and Pseudo stem Lignocellulose. 2016; 5(2), 139-151.

- Ibrahim ME, Abdelgadir AY. Effect of growth rate on fiber characteristics of Eucalyptus camaldulensis wood of coppice origin grown in White Nile state, Sudan, Jour. of Nat. Resour. & Environ. 2015; 3(1683-6456): 14-23.

- Samariha A. The influence of trees’ age on the physical properties and fiber length of Eucalyptus camaldulensis in the Zabol Region at Iran. Middle-East Journal of Scientific Research. 2011; 8(5):851-854.

- Santos AJ, Pereira H, Anjos O. Characterization and within-tree variation of wood anatomy of Acacia melanoxylon. Millenium-Journal of Education, Technologies, and Health. 2018; 2(5):13-19.

- Hudson I, Wilson L, Van Beveren K. Vessel and fibre property variation in Eucalyptus globulus and Eucalyptus nitens: some preliminary results. IAWA Journal. 1998; 19(2): 111-130.

- Machado JS, Louzada JL, Santos AJ, Nunes L, Anjos O, Rodrigues J, Simões RM, Pereira H. Variation of wood density and mechanical properties of Blackwood Acacia melanoxylon R. Br. Materials & Design (1980-2015), 2014;56:975-980.

- ASTM D. Standard Test Methods for Small Clear Specimens of Timber. ASTM International. 2000; 143-94.

- Ek M, Gellerstedt G, Henriksson G. Wood chemistry and biotechnology .Walter de Gruyter. 2009.

- Tavares F, Quilhó T, Pereira H. Wood and bark fiber characteristics of Acacia melanoxylon and comparison to Eucalyptus globules. Cerne 2011; 17(1) 61-68.

- Mercy OB, Adeola FJ, Olajide OA, Babatunde A, Sunday FJ. Evaluation of fiber characteristics of Ricinodedron heudelotii Baill, Pierre Ex Pax for pulp and paper making. International Journal of Science and Technology .2017; 6(1):634-641.

- Jorge F, Quilhó T, Pereira H. Variability of fibre length in wood and bark in Eucalyptus globulus. IAWA Journal. 2000; 21(1): 41-48.

- Plomion C, Leprovost G, Stokes A. Wood formation in trees. Plant physiology. 2001; 127(4), 1513-1523.

- Horacek P, Slezingerova J, Gandelova L. Effects of environment on the xylogenesis of Norway spruce (Picea abies [L.] Karst.). Tree-ring analysis: biological, methodological and environmental aspects. CABI publishing: Wallingford, UK. 1999; 33-53.

- Santos A, Anjos O, Simões R. Papermaking potential of Acacia dealbata and Acacia melanoxylon, Appita J. 2006; 59(1), 58-64.

- Onuorah OE. Reliminary Investigation of the potentials of six Nigerian grown Hardwood species as sources of fiber for the pulp and paper industry. Nigerian J Agricult Technol.2001; 9: 17-24

- Dutt D, Tyagi CH. Comparison of various eucalyptus species for the morphological, chemical, pulp and paper making characteristics. 2011.

- Ververis C, Georghiou K, ChristodoulakiS N, Santas P, Santas R. Fiber dimensions, lignin and cellulose content of various plant materials and their suitability for paper production, Industrial Crops and Products. 2004; 19(3), 245-254. DOI:10.1016/J.INDCROP.2003.10.006.

- Lim SC, Gan KS.Some physical properties and anatomical features of 14-year-old Acacia mangium. Journal of Tropical Forest Products. 2000; 6(2), pp.206-213.

- Quintanar Isaías A, Velázquez Núñez M, Solares Arenas F, Olvera P, de la Paz C, Torre-Blanco A.Secondary stem anatomy and uses of four drought-deciduous species of a tropical dry forest in México. Revista de biología tropical. 2005; 53(1-2):29-48.

- Santos A, Anjos O, Amaral ME Gil N, Pereira H, Simões R. Influence on pulping yield and pulp properties of wood density of Acacia melanoxylon. Journal of wood science. 2012; 58(6):479-486.

- Santos A, Amaral ME, Vaz A, Anjos O, Simo˜es R Effect of Eucalyptus globulus wood density on papermaking potential. Tappi J 2008; 7(5):25–32.

- Miranda I, Gominho J, Pereira H. Incorporation of bark and tops in Eucalyptus globulus wood pulping. Bioresources. 2012; 7(3), 4350-4361.

- Emerhi EA. Variations in anatomical properties of Rhizophora racemosa (Leechm) and Rhizophora harrisonii (G. Mey) in a Nigerian mangrove forest ecosystem. International Journal of Forest, Soil and Erosion. 2012; 2(2): 89-96.

- Quilhó T, Pereira H, Richter HG. Within–tree variation in phloem cell dimensions and proportions in Eucalyptus globulus. IAWA Journal 2000; 21(1):31-40.

- Zobel BJ, Buitjeenen JP. Wood Variation Its Causes and Control Springer-Verlag. New York. 1989.

- Izekor DN, Fuwape JA. Variations in the anatomical characteristics of plantation grown Tectona grandis wood in Edo State, Nigeria. Archives of Applied Science Research. 2011; 3(1): 83-90.

- Jorge F. Variabilidade anatómica, física e química Madeira da Eucalyptus globulus Labill. Dissert~ ao de doutoramento. Universidade Técnica de Lisboa. Lisboa. 1994.

- Burdon RD, Kibblewhite RP, Walker JC, Megraw RA, Evans R, Cown DJ. Juvenile versus mature wood: a new concept, orthogonal to corewood versus outer wood, with special reference to Pinus radiata and P. taeda. Forest science. 2004; 50(4): 399-415.

- Agnihotri S, Dutt D, Tyagi CH.Complete characterization of bagasse of early species of Saccharum officinerum-Co 89003 for pulp and paper making. BioResources.2010; 5(2):1197-1214.

- Amidon TE. Effect of the wood properties of hardwoods on kraft paper properties. Tappi. 1981; 64(3) :123-126.

- Anjos O, Santos AJ. Simoes, R. Effect of Acacia melanoxylon fibre morphology on papermaking potential. Appita Journal: Journal of the Technical Association of the Australian and New Zealand Pulp and Paper Industry. 2011; 64(2):185.

- Patt R, Kordsachia O, Fehr J. European hardwoods versus Eucalyptus globulus as a raw material for pulping. Wood Science and Technology. 2006; 40(1):39-48.

- Kiaei M, Tajik M, Vaysi R. Chemical and biometrical properties of plum wood and its application in pulp and paper production. Maderas. Ciencia y tecnología. 2014; 16(3):313-322.

- Ona T, Sonoda T, Ito K, Shibata M, Tamai Y, Kojima Y, Ohshima J, Yokota S, Yoshizawa N, Investigation of relationships between cell and pulp properties in Eucalyptus by examination of within-tree property variations. Wood Science and Technology. 2001; 35(3): 229-243.

- Ogunjobi KM, Adetogun AC, Omole AO. Assessment of variation in the fibre characteristics of the wood of Vitex doniana Sweet and its suitability for paper production. Journal of Research in Forestry, Wildlife and Environment. 2014; 6(1):39-51.

- Hemmasi AH, Samariha A, Tabei A, Nemati M, Khakifirooz A. Study of morphological and chemical composition of fibers from Iranian sugarcane bagasse. American-Eurasian J. Agric. & Environ. Sci. 2011; 11(4): 478-481.

- Brindha D, Vinodhini S, Alarmelumangai K. Fiber dimension and chemical contents of fiber from Passiflora foetida, l. and their suitability in paper production. Sci Res Rep. 2012; 2(3):210-219.

- Nisgoski S, Trianoski R, de Muniz GIB, de Matos JLM, Batista FRR. Anatomia da Madeira de Toona ciliata características das fibras para produção de papel. Floresta. 2011; 41(4).

- Yahya R, Sugiyama J, Silsia D, Gril J. Some anatomical features of an Acacia hybrid, A. mangium and A. auriculiformis grown in Indonesia with regard to pulp yield and paper strength. Journal of Tropical Forest Science. 2010; 343-351.

- Nicholas I, Brown I. Blackwood: a handbook for growers and users. New Zealand Forest Research Institute Limited. 2002.

- Wimmer R, Downes G, Evans R, French J. Effects of site on fibre, kraft pulp and handsheet properties of Eucalyptus globulus. Annals of Forest Science. 2008; 65(6).

- Ilic J, Boland D, McDonald M, Downes G, Blakemore P. Wood density phase 1: state of knowledge. National Carbon Accounting System Technical Report No. 18. Australian Greenhouse Office. 2000.

- Desalegn G, Kelemewerk S, Gebeyehu D. Forest Products Utilization Research in Ethiopia: Highlights on Major Achievements and Contributions. Ethiopian Environment and Forest Research Institute, Addis Ababa. 2015; 122.

- Chowdhury Q, Ishiguri F, Iizuka K, Hiraiwa T, Matsumoto K, Takashima Y, Yokota S, Yoshizawa N Wood property variation in Acacia auriculiformis growing in Bangladesh. Wood and Fiber Science. 2009; 41(4):359-365.

- Makino K, Ishiguri F, Wahyudi I, Takashima Y, Iizuka K, Yokota S. Yoshizawa N. Wood properties of young Acacia mangium trees planted in Indonesia. Forest Products Journal. 2012; 62(2):102-106.